Manufacturing has evolved dramatically in recent decades, from manual assembly lines to fully automated smart factories. One of the most transformative trends in recent years is the application of artificial intelligence (AI) to detect anomalies across the production cycle. Anomaly detection in manufacturing refers to the use of data-driven systems to identify irregularities or deviations from expected behaviour in machines, processes, or product quality, often before they escalate into costly failures or defects.

In a sector where precision, efficiency, and uptime are critical, catching anomalies early can save both time and resources. Let’s explore how AI is powering anomaly detection, the specific use cases making headlines, and the tangible benefits companies are reaping.

What Is Anomaly Detection in Manufacturing?

Anomaly detection is a process of identifying data patterns that do not conform to expected behaviour. In manufacturing, this can mean:

- A sudden temperature rise in a machine

- Unexpected vibrations in a motor

- A defect in a product’s shape or dimension

- A drop in production speed

- Sensor readings falling outside acceptable thresholds

Traditional anomaly detection methods required manual monitoring or rule-based thresholds. These approaches, though helpful, often miss subtle indicators of larger problems. With AI and machine learning, the detection process becomes more proactive, adaptive, and precise.

Today, anomaly detection in manufacturing leverages algorithms that can learn from historical data, recognise normal operating conditions, and spot deviations in real-time, without needing explicit programming.

How AI Enhances Manufacturing Defects

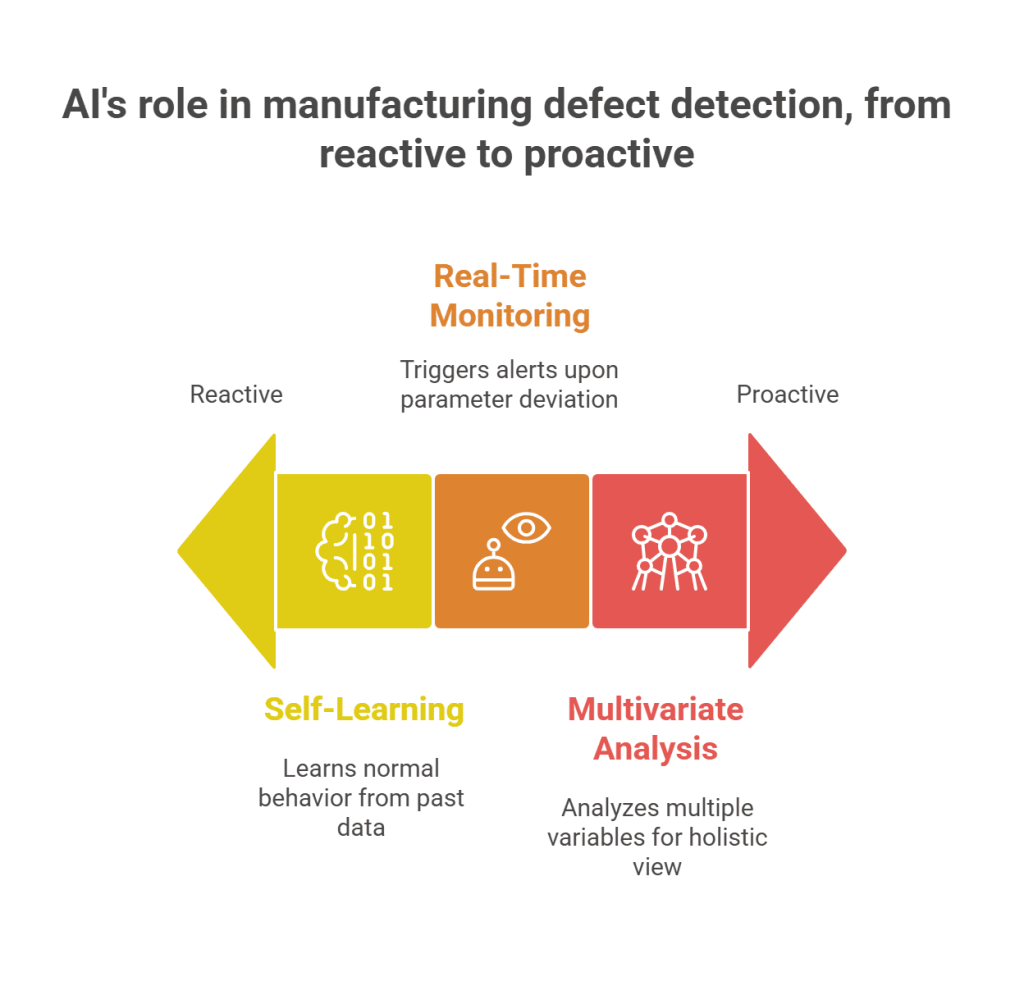

AI, particularly machine learning and deep learning, brings predictive power to anomaly detection. Here’s how:

1. Self-Learning Capabilities

AI systems learn from past production data, sensor readings, machine logs, and other inputs. Over time, they build a model of “normal behaviour” for various equipment and processes. Once established, these models can detect even the slightest irregularities, often before a human operator notices.

2. Real-Time Monitoring – AI Use in Manufacturing

With AI-driven platforms, data is monitored in real-time. The moment a parameter deviates from the norm, alerts are triggered. This minimizes downtime and prevents minor anomalies from becoming major failures.

3. Multivariate Analysis

Machines don’t fail in isolation. AI can analyse multiple variables—temperature, pressure, load, vibration, etc.—simultaneously to get a full picture of machine health. This holistic approach makes anomaly detection more reliable.

Uses of AI in Manufacturing

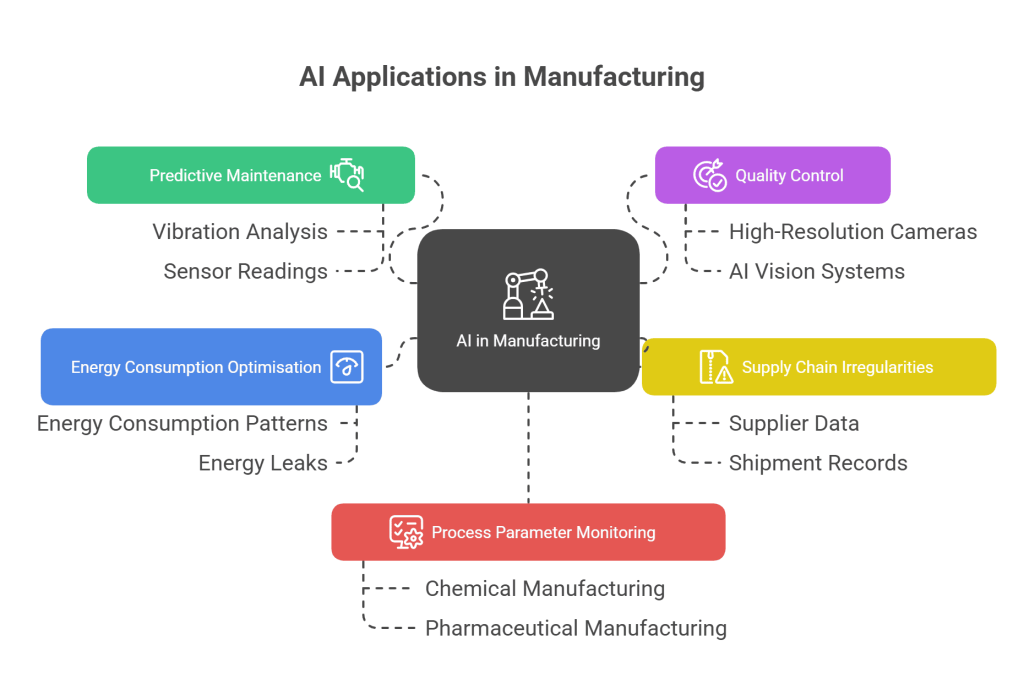

The applications of AI-powered anomaly detection span the entire manufacturing value chain. Here are some key examples:

1. Predictive Maintenance

AI can analyse vibration patterns, sound frequencies, oil analysis data, and sensor readings to detect wear and tear in equipment. For example, an impending motor failure might manifest as a slight change in vibration long before the motor fails. Detecting this anomaly early ensures maintenance can be scheduled proactively, preventing unexpected breakdowns.

2. Quality Control in Production Lines

Manufacturers use high-resolution cameras and AI vision systems to inspect products in real-time. If a product has a minor crack, misalignment, or deformation that a human eye might miss, the system flags it instantly. This makes anomaly detection in manufacturing vital for maintaining consistent quality.

3. Supply Chain Irregularities

AI can detect anomalies in procurement patterns, delivery delays, or material inconsistencies. By analysing supplier data, order logs, and shipment records, companies can preempt supply chain disruptions.

4. Energy Consumption Optimisation

Excessive power usage often signals an underlying fault. AI models detect anomalies in energy consumption patterns to help reduce costs and identify energy leaks or inefficiencies.

5. Process Parameter Monitoring

In chemical or pharmaceutical manufacturing, even a small deviation in process parameters can affect product efficacy. AI tracks multiple variables to ensure recipes and mixtures remain within desired thresholds.

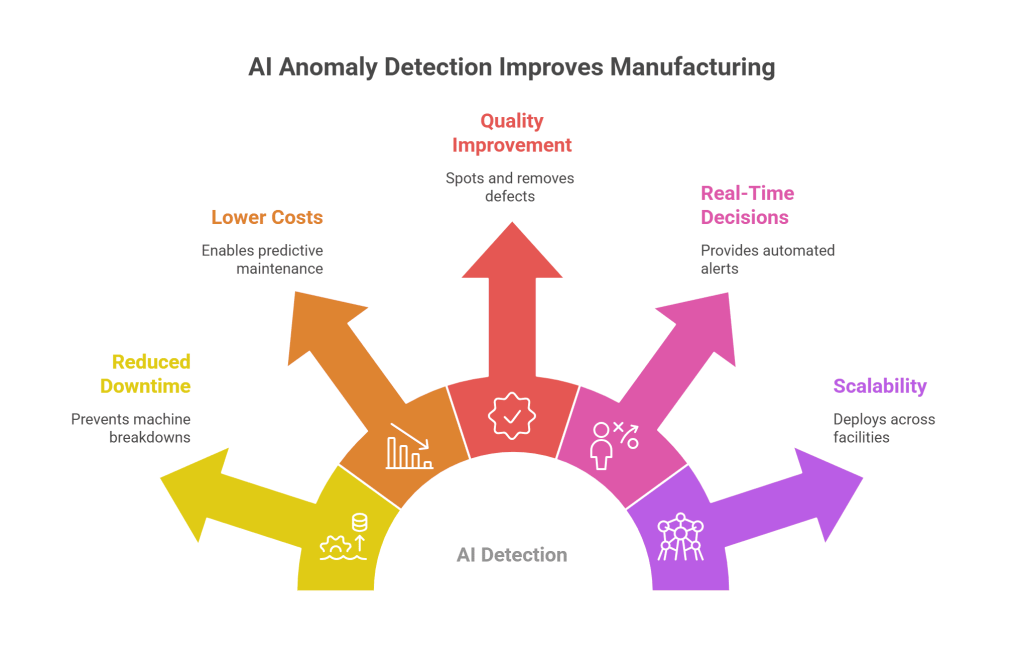

Benefits of AI-Powered Anomaly Detection in Manufacturing

Anomaly detection using AI yields several significant benefits:

1. Reduced Downtime

By identifying faults before they cause machine breakdowns, manufacturers can schedule repairs during planned downtime, maximising uptime and productivity.

2. Lower Maintenance Costs

Traditional maintenance is either reactive (post-failure) or preventive (routine). AI enables predictive maintenance, which is more efficient and cost-effective.

3. Improved Product Quality

Defective products damage reputation and lead to rework or waste. AI helps spot and remove defects early, maintaining high product standards.

4. Real-Time Decision Making

With automated alerts and real-time insights, floor managers can make quicker, more informed decisions.

5. Scalability Across Multiple Facilities

AI models, once trained, can be deployed across different lines, plants, or geographies. This makes anomaly detection in manufacturing highly scalable.

Implementation Challenges and Considerations

Despite its potential, implementing AI for anomaly detection isn’t plug-and-play. Manufacturers must address a few challenges:

- Data Collection and Integration: Clean, structured data from various sources is needed. Integration with legacy machines and systems can be complex.

- Model Training and Accuracy: Poorly trained models may produce false positives or miss anomalies.

- Interpretability: Black-box models can make it hard for operators to understand why an alert was triggered.

- Cybersecurity: Connected sensors and AI systems can become vulnerable if not secured properly.

To overcome these issues, manufacturers often start small—on a single line or machine—before scaling AI solutions across their facilities.

Real-World Examples

Bosch uses AI-based vibration analysis to predict machine wear in real-time, reducing unplanned downtime by over 25%.

- General Electric (GE) employs deep learning for anomaly detection in its jet engine manufacturing lines, saving millions in avoided failures.

- BMW uses computer vision to detect anomalies in vehicle paint jobs, leading to a sharp decline in rework rates.

These examples highlight that anomaly detection in manufacturing is not just theoretical—it’s transforming industry practices.

The Future of Anomaly Detection in Manufacturing

The journey has just begun. As AI algorithms become more sophisticated and as edge computing grows, we’ll see:

- Real-time anomaly detection at the device level (edge AI)

- AI agents that not only detect but also suggest fixes or take autonomous action

- Integration with digital twins for simulations before real-world deployment

- Industry-wide AI benchmarks for anomaly patterns

In the next 5–10 years, anomaly detection in manufacturing will likely become a standard part of smart factories, ensuring that operations are not just automated, but intelligent and self-correcting.

FAQs: Anomaly Detection in Manufacturing

1. What types of anomalies can AI detect in manufacturing?

AI can detect mechanical faults, quality defects, environmental inconsistencies, abnormal energy usage, and sensor failures.

2. How is anomaly detection different from traditional quality checks?

Traditional checks are manual or rules-based, while AI systems use machine learning to continuously learn and improve, enabling proactive and dynamic monitoring.

3. Is anomaly detection only for large manufacturers?

Not at all. Even small and mid-sized manufacturers can implement affordable AI-powered anomaly detection solutions on specific machines or lines.

4. How does anomaly detection improve ROI?

It reduces equipment downtime, minimises product defects, cuts maintenance costs, and increases throughput—ultimately boosting profitability.

5. Can anomaly detection be integrated with IoT sensors?

Yes. IoT sensors are often the data source for AI systems, providing real-time input for accurate anomaly detection.

Conclusion

The manufacturing world is shifting from reactive fixes to proactive intelligence. With the rise of AI, anomaly detection in manufacturing is no longer a luxury—it’s becoming a necessity. It enhances equipment reliability, streamlines quality control, and gives manufacturers a competitive edge.

As the complexity of manufacturing processes increases, having an intelligent system that watches every parameter, every second, is not just helpful, it’s game-changing. Contact Qodenext for a systematic supply chain traceability revamp.