Recent advancements in technology have revolutionized the transportation of fresh, perishable foods and vital biopharmaceuticals across vast distances without compromising their quality. While much attention is given to refrigerated transportation, it’s essential to recognize the crucial role of cold storage warehouse and refrigerated warehousing in maintaining the integrity of these goods.

In this blog, we’ll delve into the importance of cold storage, explore its various types, and understand how refrigerated warehousing facilitates the seamless operation of the entire cold chain logistics process.

Let’s begin!

What is a Cold Storage Warehouse?

In simple terms, a cold storage warehouse is a structure or facility that is built to maintain specific environmental conditions, thus ensuring the safety of temperature-sensitive items. Though on the outside, they look like normal warehouses, the inside is specially designed to protect the perishable goods and the pharmaceuticals.

Types of Cold Storage Warehouses

To delineate the basic types of cold storage warehousing, we can identify two primary components: the external warehouse structure and the internal equipment.

Additionally, there exists a third integrated option, where the racks commonly found in warehouse designs are part of the integral structure.

Irrespective of construction type, all cold storage facilities are unified in their mission to uphold a consistently controlled temperature within their confines.

In a broader classification, cold storage warehousing typically falls into two main categories dictated by the required temperature:

1. Refrigerated Storage

Maintaining a controlled temperature ranging from 0 to 10 °C. This category caters to items such as perishable food items, where the objective is to preserve produce by retarding spoilage and extending its shelf life.

2. Freezer Storage

Operating at temperatures between -30 to 0°C, this type of storage is designed to maintain products in a fully frozen state. Freezer warehouses are crucial for preserving the integrity of goods, preventing damage, and ensuring products remain in their optimal condition.

Each type of cold storage serves a distinct purpose, with refrigerated storage primarily focusing on extending the longevity of perishable goods, while freezer storage is essential for preserving products in a frozen state without compromising their quality.

How to Build a Cold Storage Warehouse?

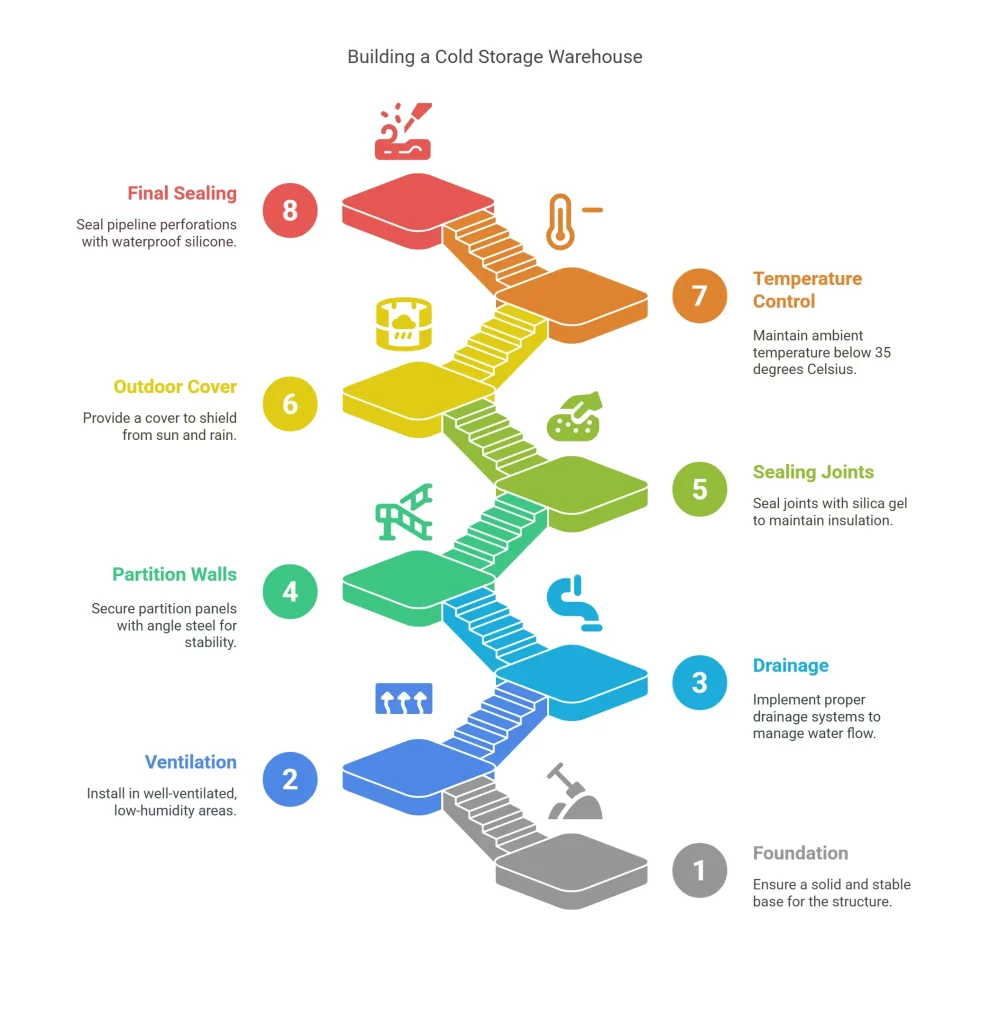

Consider the following tips when building a cold storage warehouse:

- Ensure that cold storage is installed on a solid and stable foundation.

- Install cold storage in well-ventilated, low-humidity areas, preferably within a shed protected from light and rain.

- Proper drainage is essential, directing water through drain pipes to ensure free flow away from the storage area.

- For combined cold storage, a level concrete base is necessary. Uneven ground requires levelling for proper installation.

- Secure partition wall panels using angle steel for stability.

- Check and seal joints of combined cold storage with silica gel as needed to maintain insulation.

- If installing cold storage outdoors, provide a cover to shield from sun and rain exposure.

- Avoid installing U-shaped pipes on drain pipes to prevent corrosion risks.

- Maintain ambient temperature below 35 degrees Celsius for efficient operation and ensure space for unit maintenance.

- Apply sponge tape carefully to the edges of storage boards to prevent collisions and ensure proper sealing.

- Install U-shaped pipes on drain pipes to prevent leakage, insects, and rodent intrusion.

- Consult assembly diagrams when installing movable cold storage due to varied board types.

- Gradually tighten hooks to close board seams evenly, avoiding excessive force to prevent damage.

- Keep cold storage away from heating appliances to maintain the desired temperature.

- Seal all pipeline perforations on combined cold storage boards with waterproof silicone after installation.

- Address condensation issues during installation, especially in high humidity conditions, to prevent moisture-related problems.

Success in cold storage management hinges on mastering fundamental practices and empathising with customer needs.

Maintaining a Cold Storage Warehouse

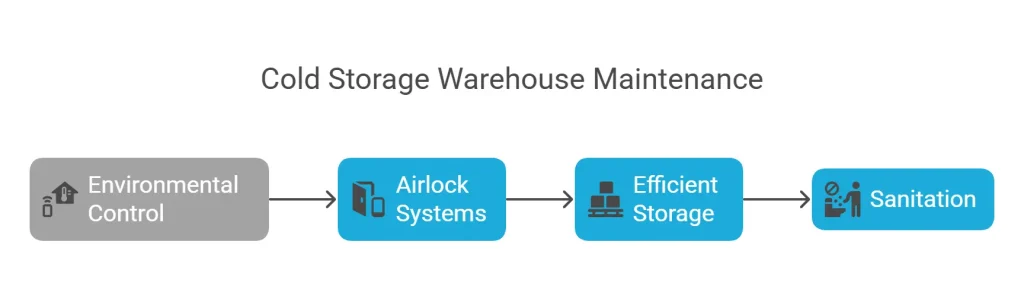

1. Environmental Control

Cold storage warehouses use temperature and humidity sensors to maintain optimal conditions. Dehumidifiers help prevent ice buildup and condensation, ensuring product quality and safety.

2. Airlock Systems

To reduce temperature fluctuations during loading and unloading, airlock systems with two high-speed doors are used. These prevent simultaneous opening, minimizing heat loss and condensation.

3. Efficient Storage

Mobile pallet racking optimizes space by using a single aisle, increasing capacity by up to 80%. Drive-in racking is also effective, boosting space efficiency by up to 90%.

4. Sanitation

Strict cleaning protocols are followed to prevent microbial contamination. This includes both physical cleaning and chemical sanitization, similar to cleanroom standards.

3 Cold Storage Warehouse Examples

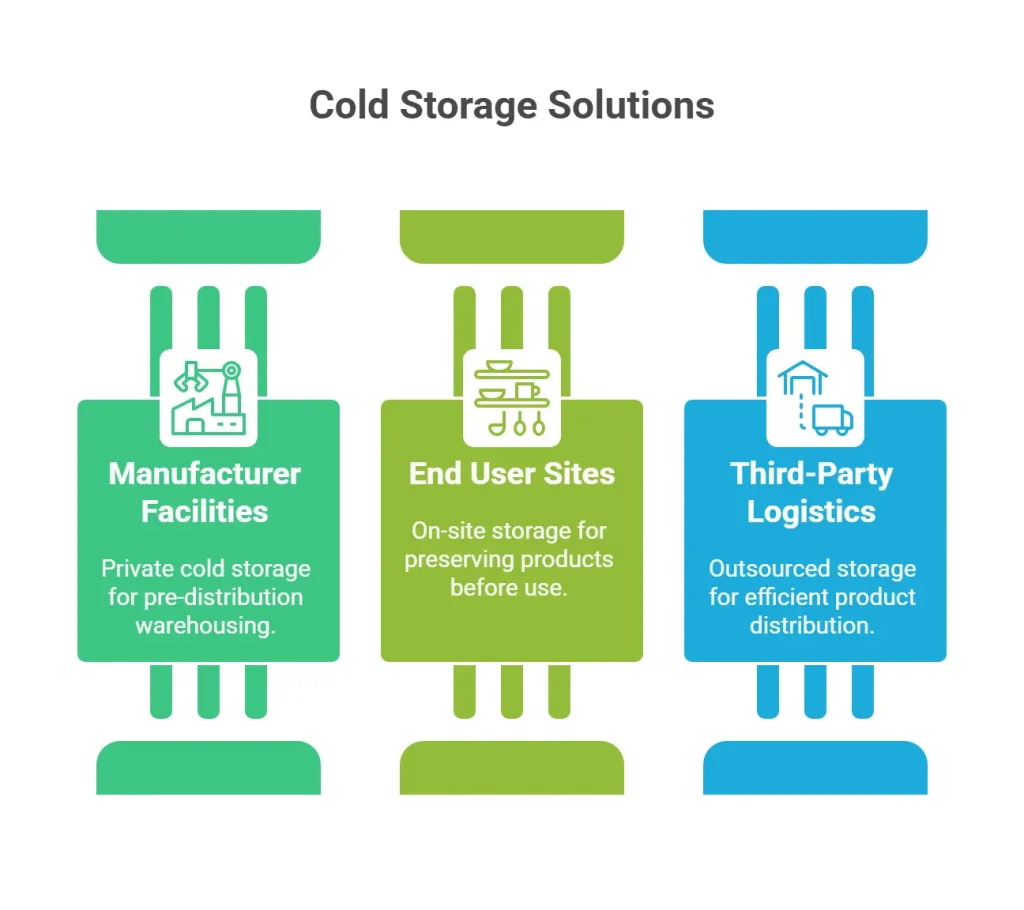

Cold storage encompasses the storage of any substance requiring temperature control to prevent decay or ensure compliance with relevant regulations. Such storage can be found in various settings:

1. Manufacturer Facilities

Manufacturers often maintain private cold storage facilities to warehouse products before distribution to end users. For instance, a meat packer based in Minneapolis may operate an on-site cold storage facility alongside a private fleet.

2. End User Sites

End users may also have their cold storage facilities to preserve temperature-sensitive products after receipt but before utilization. For example, a large hotel in Chicago may choose to buy food in bulk and store perishable items in an on-site cold storage unit.

3. Third-Party Logistics (3PL) Providers

Outsourcing cold storage to 3PL providers is common, with products stored until they’re ready for shipment. For instance, a Wisconsin cheese producer might utilize a 3PL’s cold storage facility to store dairy products until distribution to end users.

Cold Storage Warehouse Challenges with Solutions

Cold storage warehouses pose several challenges that necessitate careful consideration:

1. Cost Considerations

Cold storage is inherently more expensive than ambient temperature storage due to the energy required to maintain low temperatures.

2. Employee Comfort and Safety

Operating in sub-zero temperatures presents challenges for employee comfort and safety, requiring suitable measures and equipment to ensure their well-being.

3. Temperature Consistency

Ensuring consistent temperatures throughout the storage facility, including at points of goods receipt and dispatch, is essential for preserving product integrity.

Solutions:

- Addressing these challenges often involves strategic equipment selection, such as racking and conveyors, to optimize space utilization and streamline operations. Automation and semi-automation can also reduce labour costs and enhance efficiency.

- Popular cold storage solutions include mobile pallet racking, which maximizes floor space with a single operating aisle, potentially saving up to 40% compared to conventional pallet racking.

- Drive-in racking allows for the storage of large quantities while maximizing space efficiency by up to 90%, particularly suitable for cold and chilled goods.

- To enhance sustainability, there’s a growing investment in AGV (Automated Guided Vehicle) operated vehicles for cold store environments, aiming to improve warehouse efficiency.

- Pallet shuttle systems reduce manpower and reliance on forklift trucks, ideal for warehouses with low SKU levels requiring efficient yet compact storage systems.

- For warehouses with high product turnover, pallet flow solutions offer fast access to goods while using up to 60% less flow space, contributing to efficient operations in cold storage environments.

Conclusion

Cold storage warehouses are the most important factor in the maintenance of the quality and integrity of temperature-sensitive goods, from perishable foods to life-saving pharmaceuticals.

Although there are obstacles like the heavy initial costs and regulatory compliance, the demand for cold storage is still very big, this is due to the industries that depend on keeping the exact temperature conditions.

Businesses are looking for efficient and reliable cold storage solutions; as a result, new technologies like those provided by Qodenext can be a great help in improving operational efficiency and making cold chain logistics seamless.

FAQs: What is a Cold Storage Warehouse? Ultimate Guide

1. Is a cold storage warehouse profitable?

Cold storage warehouses can be profitable due to high demand for temperature-controlled storage, especially in the food and pharmaceutical industries. However, profitability depends on factors such as location, operational efficiency, and market conditions.

2. What are some limitations of a cold storage warehouse?

Limitations include high initial investment, ongoing energy costs, maintenance expenses, and strict regulatory requirements for temperature control and sanitation.

3. What is the cost of a 50-ton cold storage warehouse in India?

The cost of a 50-ton cold storage warehouse in India can vary widely depending on factors like size, location, construction materials, and technology used, but it could range from several lakhs to crores of rupees.

4. Are cold storage warehousing in demand?

Yes, cold storage warehouses are in demand, driven by the growth of perishable goods industries like agriculture, food, and pharmaceuticals. The need for temperature-controlled storage to maintain product quality and extend shelf life contributes to sustained demand.

5. What products require cold storage warehousing?

Cold storage is essential for a wide range of products such as fruits, vegetables, dairy products, meat, seafood, vaccines, biopharmaceuticals, cosmetics, and certain chemicals. Any product sensitive to temperature fluctuations benefits from cold storage.

6. How is energy efficiency achieved in cold storage warehouses?

Energy efficiency in cold storage is achieved through high-quality insulation, LED lighting, temperature zoning, automated systems, and technologies like motion-activated doors and smart HVAC systems. These methods help reduce energy consumption while maintaining consistent temperatures.

7. How is hygiene maintained in a cold storage warehouse?

Hygiene is maintained through strict cleaning protocols, use of antimicrobial surfaces, scheduled sanitization, pest control, proper drainage systems, and employee hygiene practices. Maintaining cleanliness is crucial to preventing product contamination and complying with health regulations.