These days, launching a business might seem straightforward, yet sustaining its operations smoothly and ensuring profitability remains a significant challenge for most entrepreneurs. At its core, a thriving business prioritises two key principles: the efficient production and sale of goods. Effective management of operations and supply chain is paramount for navigating the complexities accompanying growth and success.

This blog delves into the essence of supply chain and operations management, shedding light on its indispensable role in business endeavours.

Defining Supply Chain Operations

Supply chain management means keeping track of how things move from one place to another and making sure everything goes smoothly. In the candle business, this involves deciding which scents to make, ordering materials from suppliers, arranging transportation, checking inventory, and working with a company to ship orders.

For a deeper dive into the critical role of end-to-end visibility, see why end-to-end visibility is important for supply chain management.

It involves:

- Deciding on the assortment and quantity of various candle scents to produce.

- Initiating procurement of raw materials from suppliers.

- Coordinating the timing and logistics of transporting both raw materials and finished products.

- Conducting regular audits of inventory and tracking inventory levels over time.

- Collaborating with a third-party logistics provider for order fulfillment.

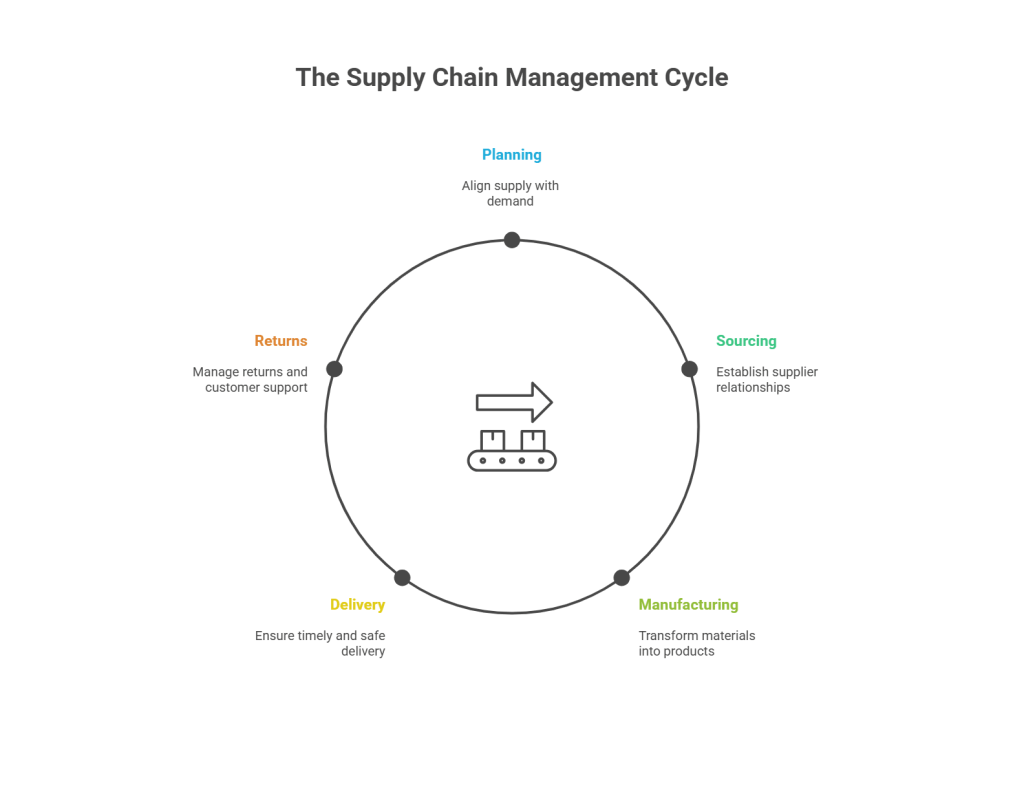

The 5 Phases of Supply Chain Management

A supply chain manager’s role extends beyond traditional logistics and purchasing; it involves finding ways to enhance efficiency, cut costs, and prevent shortages while preparing for unexpected events. The SCM process typically comprises five phases:

1. Planning

This stage kicks off SCM by aligning supply with customer and manufacturing demands. Companies predict future needs, considering materials, equipment capacity, and staffing. Demand forecasting in supply chain management is essential for accurate planning. Many use enterprise resource planning (ERP) software for coordination.

2. Sourcing

Strong supplier relationships are crucial for effective SCM. This phase involves collaborating with vendors to procure materials meeting manufacturing specs, at competitive prices, with flexibility for emergencies, and a track record of timely delivery.

3. Manufacturing

Here, raw materials are transformed into finished products through various tasks like assembly, testing, and packaging. Deviations from plans, like excess waste or resource usage, require corrective action.

4. Delivery

After production and sales, products must reach customers promptly and safely. A robust logistics setup ensures timely and cost-effective delivery, even with unforeseen challenges like extreme weather. Explore types of logistics in supply chain management for more.

5. Returns

SCM concludes with handling product returns and customer support. Reverse logistics manage returned items, ensuring refunds and addressing underlying issues to reduce future returns.

Supply Chain Models

Different companies adopt models tailored to their goals and circumstances:

- Continuous flow: Consistent production for stable demand.

- Agile: Flexibility for unpredictable demand or custom orders.

- Fast: Quick turnover for short-lived trends.

- Flexible: Scalability for seasonal demand fluctuations.

- Custom: Tailored approach for specialized industries.

Example of SCM

Walgreens Boots Alliance Inc. revamped its supply chain by leveraging technology and big data to enhance forecasting and inventory management across its vast network of stores and suppliers. This strategic shift included appointing a chief supply chain officer and integrating SCM into its ESG initiatives, emphasizing sustainability and transparency in its operations.

Importance of Supply Chain Management

Supply chain management holds significance as it enables businesses to accomplish various objectives. For instance, overseeing manufacturing processes can enhance product quality, mitigating the likelihood of recalls and legal issues while bolstering consumer trust in the brand.

Effective supply chain management systems aim to reduce costs, waste, and production cycle times. The prevailing industry standard is the just-in-time supply chain, where retail sales trigger automatic replenishment orders to manufacturers, enabling swift restocking of shelves.

Analyzing data from supply chain partners offers a pathway for further enhancement. The Chief Information Officer (CIO) identifies three scenarios where effective SCM adds value:

-

Cost Reduction & Efficiency: Effective SCM reduces costs, waste, and production cycle times. For best practices, see supply chain management best practices.

-

Data-Driven Decisions: Analyzing data from supply chain partners offers further enhancement. Supply chain management tools can help you leverage analytics for better decision-making.

-

Risk Management: Prepare for disruptions with insights from supply chain management risks and challenges and supply chain disruption.

-

Inventory Optimization: Maintain the right stock levels with inventory optimization.

-

Global Trends: Stay updated with what is global supply chain trends.

1. Identifying Potential Issues

Data analysis allows manufacturers to foresee shortages before customers experience dissatisfaction due to unfulfilled orders.

2. Optimizing Pricing Dynamically

For seasonal products with limited shelf life, retailers often resort to discounting or scrapping. Similarly, industries with perishable offerings adjust prices based on demand. Analytic software aids in forecasting, enabling better margin management even for durable goods.

3. Enhancing “Available to Promise” Inventory Allocation

Analytical tools dynamically allocate resources and schedule work based on sales forecasts, actual orders, and promised raw material deliveries. This reduces errors in order fulfillment and ensures accurate product delivery timelines.

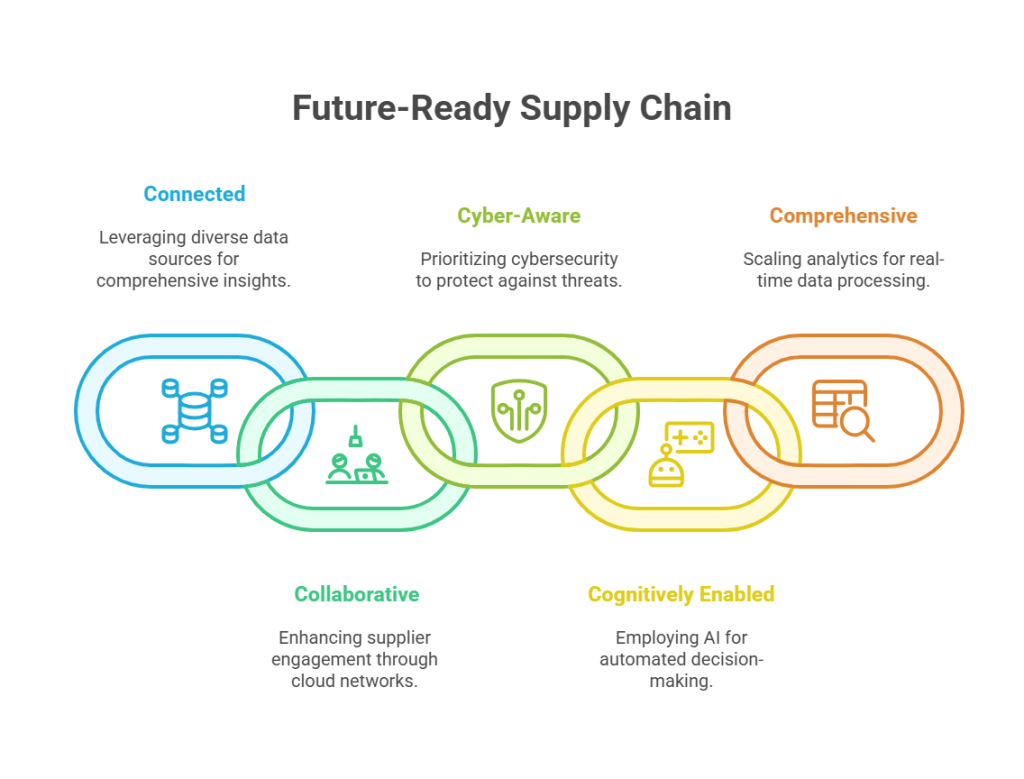

Key Features of Supply Chain Management

The supply chain serves as the primary interface between businesses and customers, profoundly impacting the company’s reputation and long-term viability. IDC outlines the five Cs of future-ready supply chain management:

1. Connected

Leveraging a range of data sources, including social media, IoT, ERP, and B2B integration tools, to access both structured and unstructured data.

2. Collaborative

Enhancing collaboration with suppliers through cloud-based commerce networks, facilitating multi-enterprise engagement.

3. Cyber-Aware

Prioritizing cybersecurity measures to safeguard systems against intrusions and cyber threats, recognizing it as an enterprise-wide imperative.

4. Cognitively Enabled

Employing AI platforms as control towers to orchestrate decisions and actions across the supply chain, enabling automation and self-learning capabilities.

5. Comprehensive

Scaling analytics capabilities to process real-time data, ensuring comprehensive and swift insights to address evolving supply chain demands.

Many supply chains are already embracing these principles, with increased participation in cloud-based networks and substantial efforts to bolster analytics capabilities.

Traceability in Supply Chaim Management

When evaluating SCM options, prioritize systems incorporating blockchain technology to seamlessly integrate visibility and insights into your SCM processes. This ensures traceability, repudiation, and trust throughout your supply network.

The food industry, in particular, stands to gain significantly from such SCM advancements. LiDestri Food and Drink’s experience exemplifies this, as it effectively manages a complex supply chain, resulting in heightened visibility, more accurate forecasting, and increased profitability, while fostering stronger trust with customers.

Today’s cutting-edge SCM systems serve as comprehensive suites, managing and optimizing supply chains as unified ecosystems. Being fully integrated cloud technologies, these systems provide 100% visibility across the supply chain and possess the flexibility to adapt to market dynamics.

With a modern, demand-driven approach to supply chain management, businesses can address challenges like heightened customer expectations, shorter product lifecycles, and fluctuating demand with confidence.

The Future of Supply Chain Management

The future of supply chains revolves around responsiveness and prioritizing the customer experience within a network-based model rather than a linear one. Each node within this network must be adaptable and responsive to consumer needs while also navigating complexities like sourcing, trade policies, and shipping methods.

Advanced technologies will play an increasingly pivotal role in enhancing transparency, visibility, and connectivity throughout this network, empowering more effective SCM utilization. SCM planning will evolve towards greater intelligence, continuously incorporating consumer demands and necessitating adaptability as a core requirement.

Future SCM systems will aim for tighter integration between planning and execution, a gap that currently exists for many enterprises. With the increasing demand for speed and accuracy in SCM, it’s crucial to equip your supply chain for the future with an intelligent SCM system.

Conclusion

In summary, running a smooth supply chain is crucial for businesses to keep growing and making money. By focusing on making things efficient and working well with others in the supply chain, companies can meet customer needs and handle challenges.

With new tech like smart systems and blockchain, the future looks bright for making supply chains even better. Qodenext offers helpful solutions for businesses to improve their supply chain operations and stay strong in the market.

FAQs: Guide to Supply Chain Operations 2024

1. What are the 7 operational processes in supply chain operations?

The 7 operational processes in supply chain operations include procurement, production, inventory management, distribution, transportation, warehousing, and customer service.

2. What are the limitations of supply chain management?

Limitations for supply chain management include disruptions, complexity, lack of coordination, information asymmetry, and dependence on external factors.

3. How important is logistics in supply chain operations?

Logistics is crucial in supply chain operations as it involves the efficient flow of goods, information, and finances from the point of origin to the point of consumption.

4. What are the types of flow in supply chain management?

Types of flow in supply chain management include product flow, information flow, and financial flow, ensuring seamless coordination throughout the supply chain network.

5. What is the role of AI in supply chain management?

AI helps automate routine tasks, predict demand, optimize routes, and make smarter decisions by analyzing large sets of supply chain data in real time.

6. How does blockchain improve supply chain traceability?

Blockchain ensures that every step in the supply chain is recorded securely and transparently. This makes it easier to trace products, prevent fraud, and build trust with customers.

7. What is end-to-end visibility in supply chain management?

It means being able to track and monitor products, materials, and information from the start (like raw material sourcing) to the end (delivery to the customer) in real time.

8. Why is inventory optimization important?

Optimizing inventory helps businesses keep just the right amount of stock—reducing storage costs, avoiding overstocking or stockouts, and improving cash flow.

9. What is just-in-time (JIT) supply chain strategy?

JIT is a system where products are made or bought only when needed, helping reduce waste and storage costs. It requires precise planning and coordination with suppliers.

10. How can businesses manage supply chain risks?

By identifying potential disruptions early, having backup suppliers, diversifying sourcing, and using tools to monitor risks in real time, businesses can stay prepared.