Introduction

In the swiftly evolving landscape of inventory management, maintaining a competitive edge is paramount for operational excellence and business triumph. One pivotal facet demanding meticulous consideration is Pipeline Inventory. Within this all-encompassing guide, we delve into the intricacies of pipeline inventory, offering profound insights, concrete examples, and strategic approaches to elevate your stock flow optimization.

Understanding Pipeline Inventory

What Constitutes Pipeline Inventory?

Pipeline Inventory delineates the inventory or stock dynamically transitioning or progressing through distinct stages within the intricate web of the supply chain. This encompasses commodities traversing from suppliers to manufacturers, within the production stages, or from manufacturers to distributors and retailers. Essentially, pipeline inventory epitomizes products navigating various phases of production, transportation, or distribution.

Spearheading the optimization of pipeline inventory is imperative for businesses, ensuring an uninterrupted and efficient flow of goods across the supply chain. It entails vigilant monitoring and supervision of inventory movement at each stage, from production initiation to distribution, mitigating disruptions, and fine-tuning the overall inventory management mechanism.

In simpler terms, pipeline inventory embodies the inventory on the move, whether it pertains to raw materials in transit towards production facilities, work-in-progress during manufacturing, or finished goods an route to their ultimate destination. Proficient management of pipeline inventory stands as a linchpin for sustaining an agile and streamlined supply chain, consequently contributing to operational triumphs within the business.

Decoupling Inventory

Decoupling inventory emerges as a strategic paradigm in inventory management, orchestrating buffers or stock reserves amid diverse stages of the production or distribution continuum. The raison d’être of decoupling inventory is to amplify adaptability and curtail the repercussions of disruptions or delays within the supply chain.

In more straightforward terms, decoupling inventory functions as a protective barrier against uncertainties, introducing a buffer amid assorted phases of the production or distribution spectrum. This buffer serves to pre-emptively counteract disruptions from permeating the entire supply chain, empowering businesses to sustain seamless operations.

Illustratively, in the realm of manufacturing, decoupling inventory might encompass the storage of surplus raw materials or partially completed products strategically positioned at pivotal junctures in the production line. This tactical placement of inventory buffers serves to absorb fluctuations in production rates or unanticipated delays, ensuring the overarching supply chain retains resilience and adaptability to unforeseen alterations.

Decoupling inventory is a proactive measure designed to minimize the cascading effects of disruptions, furnishing businesses with the latitude needed to navigate challenges and perpetuate a steady flow of goods. This strategic approach to inventory management proves indispensable for optimizing operational efficiency and responsiveness within the dynamic environs of contemporary business landscapes.

Pipeline Inventory Example

Real-world Illustration of Pipeline Inventory

A tangible manifestation of pipeline inventory in operation manifests in the domain of automotive manufacturing. Let’s envision a scenario where a company fabricates automobiles.

Procurement of Raw Materials:

- The inception of the pipeline inventory commences with the acquisition of raw materials like steel, plastic, and electronic components. These materials are in transit from suppliers to the manufacturing facility.

Manufacturing Undertakings:

- Subsequent to the arrival of raw materials, they become integral to the work-in-progress (WIP) inventory during the manufacturing process. At this juncture, diverse components coalesce, and the partially completed vehicles traverse through distinct stages on the production line.

Inventory in Transit:

- The purview of pipeline inventory also encompasses the completed vehicles in transit from the manufacturing facility to distribution centers or dealerships. This phase entails the conveyance of the finished products to their final destinations.

Dispensation to Dealerships:

- Upon reaching distribution centers, the vehicles continue to constitute part of the pipeline inventory until they are dispensed to individual dealerships. This stage involves the logistical orchestration of moving products from a centralized locale to regional points.

Retailer’s Inventory:

- Finally, when the vehicles grace the dealership, they merge into the retailer’s inventory until they are procured by end consumers. This incorporates cars on display, test drive vehicles, and those awaiting collection by customers.

In this instance, pipeline inventory encompasses the entirety of the automotive product lifecycle, from the procurement of raw materials to the conclusive sale at the dealership. Each phase entails the perpetual flux of inventory, and adroit management of this pipeline proves quintessential for the automotive entity to satisfy demand, curtail stockouts, and perpetuate an unbroken supply chain.

Pipeline Stock in Inventory Management

Pipeline stock, within the purview of inventory management, epitomizes the cumulative amalgamation of goods traversing through the assorted stages of the supply chain. It assumes a pivotal role in guaranteeing an uninterrupted flow of products from production inception to the ultimate consumer. Let’s delve into the significance and strategies affiliated with the effective administration of pipeline stock.

Understanding Pipeline Stock

Pipeline stock encompasses the entirety of inventory either in transit or at varying stages of processing, ranging from raw materials to consummated goods. In the context of inventory management, it constitutes the aggregate stock progressing through the supply chain pipeline. Proficient administration of pipeline stock proves indispensable for preserving optimal inventory levels, forestalling stockouts, and amplifying overall operational efficiency.

Importance of Managing Pipeline Stock

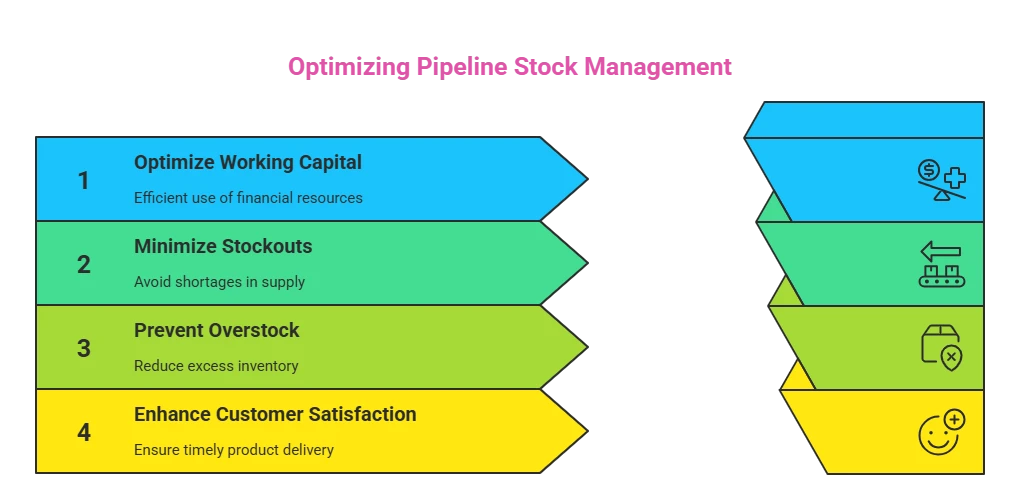

1. Optimizing Working Capital:

Competent administration of pipeline stock aids in optimizing operational capital. By judiciously harmonizing inventory levels, businesses can guarantee that capital is not unwarrantedly ensnared in surplus stock, thereby liberating resources for alternative operational requisites.

2. Minimizing Stockouts and Overstock:

Pipeline stock administration plays an instrumental role in forestalling both stockouts and surpluses. By cultivating a lucid comprehension of inventory in transit and leveraging sophisticated tracking systems, businesses can sustain the delicate equilibrium necessary to cater to demand sans excess or deficiency.

3. Enhancing Customer Satisfaction:

Timely and unwavering product availability constitutes a pivotal tenet for customer satisfaction. Proficient administration of pipeline stock ensures that products reach consumers promptly, culminating in a favorable customer experience and engendering loyalty.

Strategies for Optimizing Pipeline Stock

Real-time Monitoring Systems:

Implementation of sophisticated monitoring systems furnishes real-time visibility into the flux of pipeline stock. This facilitates proactive decision-making, curtails the hazard of disruptions, and provides insights for strategic modifications.

Anticipating Demand:

Precise demand anticipation stands as a cornerstone for pipeline stock administration. By leveraging data analytics and discerning market trends, businesses can prognosticate consumer demand, thereby facilitating enhanced inventory planning and diminishing the probability of surplus or deficit stock.

Prudent Stock Placement:

Strategically employing decoupling inventory involves the judicious placement of buffer stock at strategic points within the supply chain. This strategic positioning serves as a safety mesh, guaranteeing an uninterrupted flow of goods and alleviating the impact of unforeseen delays.

Streamlined Logistics and Transportation:

Ensuring the efficiency of logistics and transportation constitutes a paramount facet of pipeline stock administration. Rationalizing transportation processes diminishes the time goods expend in transit, thereby amplifying the overall agility and responsiveness of the supply chain.

Stock in Transit – Ensuring a Seamless Flow

In the intricate tapestry of supply chain oversight, the concept of “Stock Transit” assumes a pivotal role, functioning as a bridge linking production and consumption. This article probes the importance of inventory on the move and delineates strategies to ensure a seamless flux within the supply chain.

Understanding Stock in Transit

Defining Stock in Transit:

Inventory on the move characterizes stock actively transitioning from one location to another within the supply chain. This may encompass raw materials en route to production facilities, work-in-progress navigating manufacturing stages, or consummated products journeying towards distribution centers or end consumers.

Dynamic Nature of Stock in Transit:

In contradistinction to stagnant inventory, inventory on the move exudes dynamism and embodies the pulse of the supply chain. It mandates vigilant monitoring and strategic foresight to preclude bottlenecks and delays, thereby guaranteeing a smooth progression of goods from origin to terminus.

Importance of Managing Stock in Transit

Minimizing Temporal Gaps:

Competent administration of inventory on the move proves critical for minimizing temporal gaps. Through the optimization of transportation routes and logistics, businesses can guarantee the expeditious conveyance of goods to their final destination, truncating the comprehensive time consumed from production to delivery.

Averting Stockouts:

A well-regulated inventory on the move forestalls stockouts. By cultivating a lucid comprehension of inventory in motion, businesses can prophesize arrival times and modulate stocking levels to meet demand, circumventing scenarios where products become inaccessible.

Augmenting Supply Chain Transparency:

Transparency into inventory on the move augments the overarching visibility of the supply chain. Cutting-edge tracking systems and instantaneous monitoring empower businesses to trace the trajectory of goods, discern potential predicaments, and execute judicious decisions to perpetuate a seamless flux.

Strategies for Ensuring a Seamless Flow of Stock in Transit

1. Cutting-edge Monitoring Systems:

Implementation of cutting-edge monitoring systems confers real-time visibility into the locale and status of inventory on the move. This facilitates proactive decision-making, empowering businesses to respond promptly to disruptions or delays.

2. Optimization of Transportation Routes:

Streamlining transportation routes contributes to the seamless progression of inventory on the move. Businesses can optimize routes to truncate travel time, mitigate the peril of delays, and amplify the comprehensive efficiency of the supply chain.

3. Collaboration with Logistics Partners:

Effective collaboration with logistics partners stands as a linchpin for administering inventory on the move. Unambiguous communication and coordination ensure alignment among all stakeholders, diminishing the probability of misinterpretations or inefficiencies.

4. Exploiting Predictive Analytics:

Leveraging predictive analytics enables businesses to foresee potential predicaments in inventory on the move. By scrutinizing historical data and market trends, businesses can proactively confront challenges, rendering the supply chain more robust.

Conclusion

In conclusion, mastering the intricacies of pipeline inventory is imperative for businesses aiming for operational excellence in 2024. From understanding the significance of decoupling inventory to implementing cutting-edge tracking systems and refining lead times, each facet contributes to a seamless supply chain. Stay at the forefront by embracing these strategies with Qodenext, ensuring that your stock traverses effortlessly through the pipeline.

FAQ: Pipeline Inventory Management

1. What is the essence of pipeline inventory?

Answer: Pipeline inventory is stock in transit or moving through supply chain stages, from suppliers to manufacturers or retailers.

2. How does pipeline inventory differ from conventional inventory?

Answer: Pipeline inventory involves goods actively moving (e.g., raw materials in transit, work-in-progress), unlike static warehouse stock.

3. Why is managing pipeline inventory crucial?

Answer: It ensures smooth goods flow, reduces disruptions, prevents stockouts, and boosts efficiency with tools like QodeNext’s solutions.

4. What role does decoupling inventory play in pipeline management?

Answer: Decoupling inventory creates buffers between supply chain stages, absorbing delays for a resilient pipeline.

5. How can businesses reduce lead times in pipeline inventory?

Answer: Use data analytics, RFID tracking, and optimized logistics to speed up stock transit and improve efficiency.

6. What technologies support pipeline inventory management?

Answer: RFID, IoT sensors, and real-time monitoring systems ensure accurate tracking and efficient pipeline management.

7. How does pipeline inventory management benefit businesses?

Answer: It optimizes working capital, prevents stockouts, ensures timely deliveries, and enhances customer satisfaction.

8. What are the challenges of pipeline inventory management?

Answer: Delays, compliance issues, and demand fluctuations. QodeNext’s tracking tools help overcome these challenges.

9. How does GST impact pipeline inventory?

Answer: GST streamlines cross-state stock transit, reducing delays and ensuring compliance in pipeline management.

10. Can pipeline inventory solutions lower costs for SMEs?

Answer: Yes, QodeNext’s solutions (₹5-20 lakh/year) reduce stockout costs and optimize pipeline flow for SMEs.

11. What is the essence of pipeline inventory?

Pipeline inventory encapsulates the inventory or stock in transit or progressing through diverse stages within the supply chain. This includes goods traversing from suppliers to manufacturers, within production, and from manufacturers to distributors or retailers.

12. How does pipeline inventory distinguish itself from conventional inventory?

Pipeline inventory diverges from conventional inventory in its active progression within the supply chain. It involves goods at varied stages, such as raw materials in transit, work-in-progress during production, and consummated products en route to distribution or retail points.

13.Why is the oversight of pipeline inventory crucial?

Efficient oversight of pipeline inventory is pivotal for guaranteeing an uninterrupted flow of goods, mitigating disruptions, and optimizing the overarching supply chain. It forestalls stockouts, augments operational efficiency, and contributes to timely product availability.

14. What role does decoupling inventory play in pipeline management?

Decoupling inventory entails strategically inserting buffers amid distinct stages of the production or distribution process. In pipeline management, it assuages the repercussions of delays and disruptions, ensuring a malleable and responsive supply chain.

15. How can businesses refine lead times in pipeline inventory management?

Businesses can refine lead times by accurately forecasting the duration goods spend at each stage of the pipeline. This entails the utilization of data analytics, integration of sophisticated tracking systems, and informed decision-making to truncate delays and elevate comprehensive efficiency.

16. What strategies can businesses employ for proficient pipeline inventory management?

Strategies for proficient pipeline inventory management encompass the application of cutting-edge tracking systems, optimization of lead times, implementation of demand forecasting, and tactical placement of buffer stock. These strategies contribute to a well-managed and responsive supply chain.