Did you know that India, the powerhouse of manufacturing, accounts for a staggering 17% of the world’s total textile and garment production? From traditional textiles to cutting-edge technology, India’s manufacturing sector is thriving like never before. However, behind every successful production lies effective production management. It’s the secret sauce that ensures smooth operations, optimized resources, and timely delivery of top-notch products. In this comprehensive guide, we will dive deep into the world of production management, unravelling its meaning, objectives, and the advantages it brings to the table. So, fasten your seatbelts as we embark on a captivating journey that will revolutionize the way you approach production management. And who knows, you might discover the key to unlocking your business’s true potential.

What is Production Management? Unveiling the Art of Efficient Production

Production management forms the backbone of efficient manufacturing processes. It involves the systematic planning, organising, coordinating, and controlling of resources and activities required to convert inputs into desired outputs. By optimising resources, minimising costs, and ensuring the timely delivery of high-quality products or services, production management serves as the cornerstone of successful operations. Let’s dive deeper into this integral concept that drives organisations forward.

Production management refers to the process of planning, organising, coordinating, and controlling the resources and activities involved in the creation of goods or services. It encompasses a wide range of functions, from raw material procurement to product delivery. The primary objective of production management is to optimise resources, minimise costs, and maximise productivity while ensuring the quality and timely delivery of products.

Objectives of Production Management: Forging a Path to Excellence

The objectives of production management revolve around achieving efficiency, quality, and customer satisfaction. Each objective plays a vital role in enhancing organisational performance and delivering value to stakeholders. Let’s explore the primary objectives of production management:

- Optimal Resource Utilisation: Production management aims to make the best use of available resources, including labour, machinery, materials, and technology, to maximise output while minimising waste.

- Cost Reduction: By streamlining processes, eliminating bottlenecks, and minimising waste, production management helps in reducing production costs, leading to higher profitability.

- Quality Control: Ensuring product quality is crucial for customer satisfaction. Production management focuses on implementing quality control measures at each stage of the production process to meet customer expectations and industry standards.

- Timely Delivery: Meeting delivery deadlines is essential for maintaining a competitive edge. Production management involves effective planning and coordination to ensure products are delivered to customers on time.

- Continuous Improvement: Production management strives for continuous improvement by analysing performance metrics, identifying areas of improvement, and implementing corrective measures to enhance efficiency and productivity.

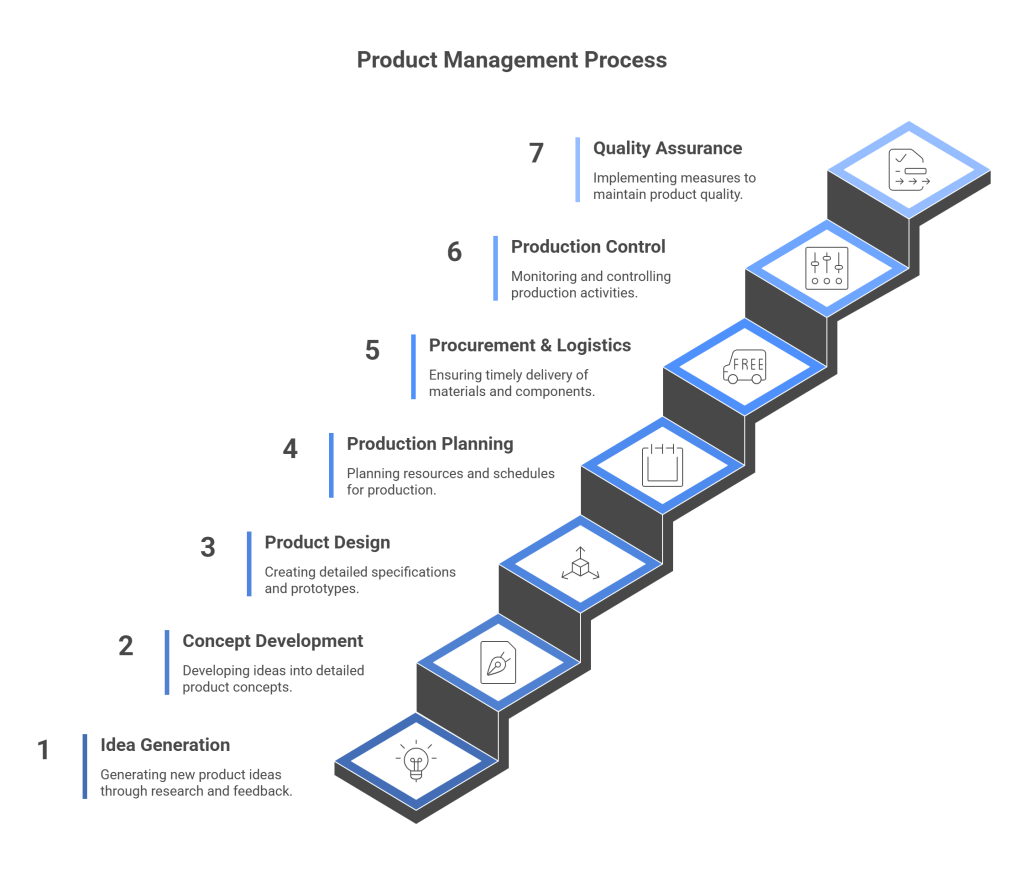

The Product Management Process

The product management process encompasses the entire lifecycle of a product, from its conceptualization to its delivery. It typically includes the following stages:

- Idea Generation: The process begins with generating ideas for new products or enhancements based on market research, customer feedback, and industry trends.

- Concept Development: Once a viable product idea is identified, it is further developed into a concept that includes product features, design, and functionality.

- Product Design: This stage involves creating detailed product specifications, including engineering drawings, prototypes, and packaging design.

- Production Planning: Planning for production involves determining the required resources, production capacity, scheduling, and sequencing of production activities.

- Procurement and Logistics: The procurement of raw materials, equipment, and other resources necessary for production is an integral part of the product management process. Efficient logistics management ensures the timely delivery of materials and components.

- Production Control: Production control is crucial for monitoring and controlling production activities to ensure adherence to planned schedules, quality standards, and cost parameters.

- Quality Assurance: Implementing quality control measures throughout the production process helps maintain product quality and minimise defects or rework.

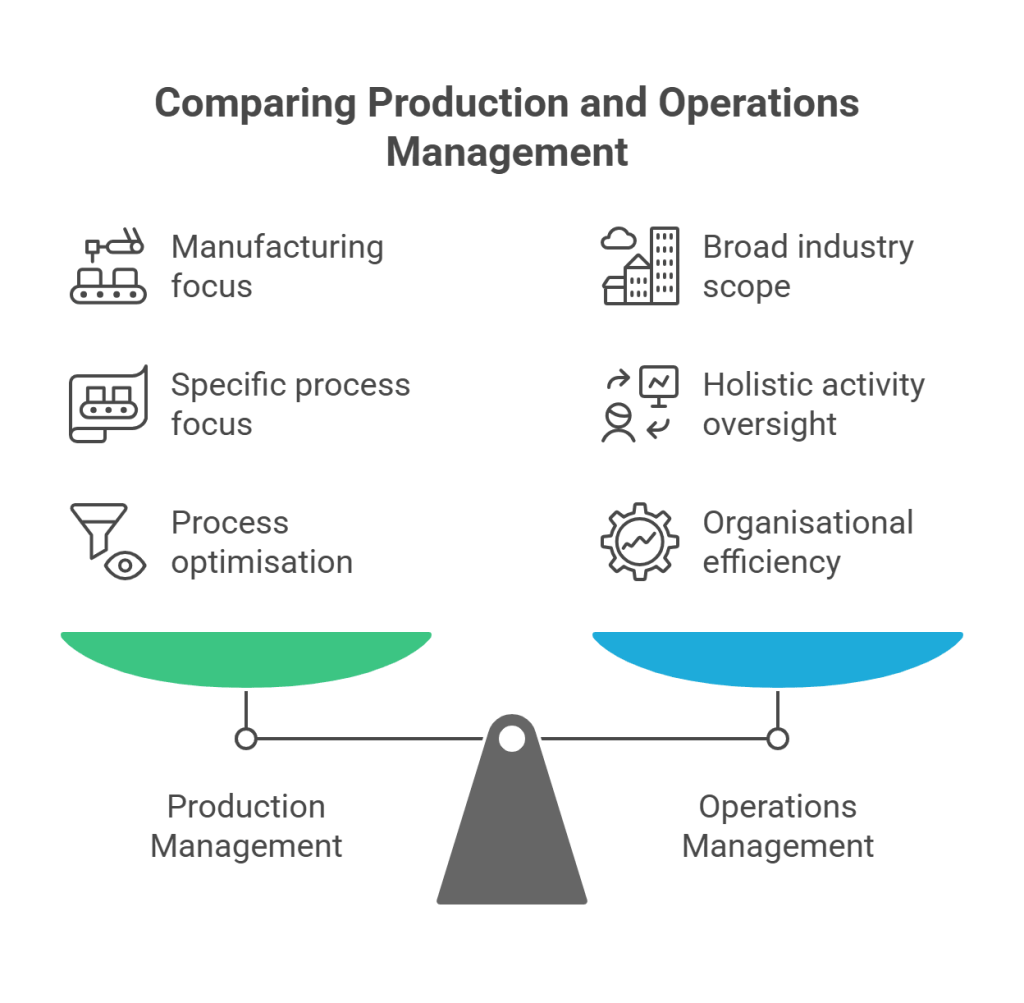

Difference between Production Management and Operations Management

While production management focuses on the conversion of inputs into outputs, operations management encompasses the holistic management of an organisation’s operations. While the two disciplines share common goals, they differ in scope and applicability. Let’s explore the differences between production management and operations management:

- Scope: Production management primarily focuses on manufacturing processes, while operations management extends to various industries, including service-oriented organisations.

- Functionality: Production management deals with the specific processes involved in creating goods or services, while operations management oversees a broader range of activities, including production, procurement, inventory management, logistics, and more.

- Perspective: Production management emphasises optimising production processes, while operations management takes a holistic view, aiming to enhance overall organisational efficiency.

- Integration: Production management is often a subset of operations management, working in synergy to achieve organisational goals efficiently.

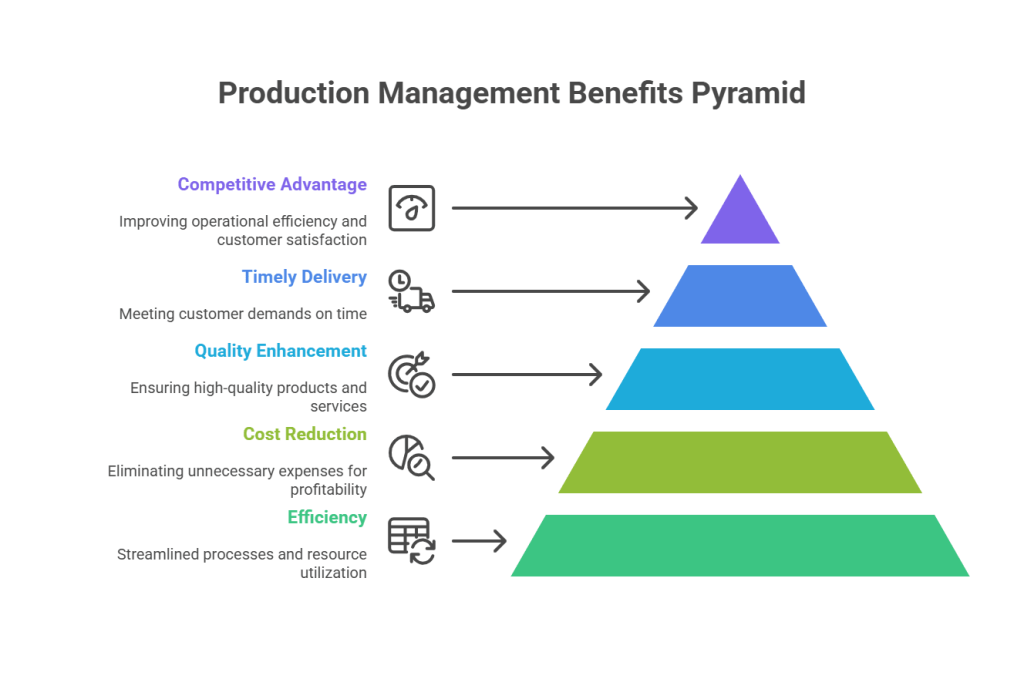

Advantages of Production Management: Unlocking the Benefits

Implementing effective production management practices offers numerous advantages for organizations striving for success:

- Improved Efficiency: Streamlined processes, waste reduction, and optimal resource utilisation lead to increased productivity and operational efficiency.

- Cost Reduction: Identifying and eliminating unnecessary expenses enhances cost-effectiveness and improves profitability.

- Enhanced Quality: Implementing quality control measures ensures the delivery of high-quality products or services, boosting customer satisfaction and brand reputation.

- Timely Delivery: Efficient planning, coordination, and control enable organisations to meet customer demands and deliver on time, fostering customer loyalty.

- Competitive Advantage: Effective production management provides a competitive edge by improving operational efficiency, reducing costs, and enhancing customer satisfaction.

Conclusion

When it comes to comprehensive production management solutions, there is one name that stands out:

Qodenext. With our expertise and innovative approach, Qodenext has helped numerous businesses streamline their production processes and achieve remarkable results.

If you’re looking to take your production management to the next level, we highly recommend exploring what Qodenext has to offer. Our tailored solutions, backed by industry experience, can provide you with the tools and strategies needed to optimise your operations, increase efficiency, and maximise profitability.

To learn more about Qodenext and how we can benefit your organisation, get on a call with us today! Take the first step towards enhancing your production management practices and unlocking your business’s true potential.Remember, seamless production management can lead to remarkable success, and Qodenext is here to guide you every step of the way.

FAQs: What is Product Management

1. What are the key functions of production and operation management?

Production and operation management involves a range of responsibilities to ensure smooth business processes. These include planning production schedules, organising resources, coordinating workflow, controlling quality, and ensuring continuous improvement. Together, these functions help businesses produce goods or services efficiently and meet customer expectations.

2. How does production control contribute to efficient operations?

Production control acts like a traffic controller for the manufacturing process. It ensures that everything goes according to plan—on time, within budget, and without compromising quality. By monitoring every stage of production, businesses can quickly detect issues, minimise downtime, and use resources more efficiently.

3. Can production management principles be applied to service-oriented industries?

Absolutely. While services don’t result in tangible products, they still require careful management of time, labour, and resources. For example, a hospital, hotel, or consultancy can apply production management principles to improve service delivery, reduce wait times, and ensure consistent quality.

4. How does production management impact cost reduction?

Production management focuses on optimising every aspect of the manufacturing process. By cutting down on waste, eliminating inefficiencies, and ensuring the right use of manpower and materials, businesses can significantly lower production costs—boosting their bottom line.

5. What role does technology play in enhancing production management processes?

Technology is a game-changer in modern production management. From automation tools and robotics to AI-driven analytics and cloud-based planning systems, tech enables faster decision-making, real-time monitoring, and better forecasting. This leads to improved efficiency, fewer errors, and smarter use of resources.

6. What is the difference between production management and operations management?

While both aim to improve efficiency and quality, production management focuses specifically on manufacturing—turning raw materials into finished goods. Operations management has a wider scope, covering all business processes, including supply chain, logistics, procurement, and services. Essentially, production management is one part of the broader operations management umbrella.

7. Why is production planning important in manufacturing?

Production planning ensures that all resources—materials, machinery, and manpower—are available when needed. It helps avoid bottlenecks, reduces idle time, and aligns production with demand. A well-structured plan also allows manufacturers to respond quickly to changes in customer orders or market conditions.

8. How does quality assurance fit into production management?

Quality assurance is integral to production management. It involves setting quality standards, checking products at various stages, and making sure they meet customer expectations. This not only reduces defects and rework but also builds trust and long-term loyalty among customers.

9. What are the major challenges in production management?

Some common challenges include managing supply chain disruptions, fluctuating customer demand, equipment breakdowns, and labour shortages. Other issues like maintaining product quality while scaling up or keeping costs low during inflationary periods also pose significant hurdles. Effective planning and the right tools help mitigate these risks.

10. How can a company like Qodenext help improve production management?

Qodenext provides innovative solutions tailored to manufacturing businesses. Their technologies support everything from inventory tracking and process automation to quality control and logistics. By implementing Qodenext’s tools, companies can streamline operations, reduce manual errors, and achieve greater control over the entire production process.