Traceability Solutions

Trace Every Product, Every Step of the Way

Seamless integration of technology to track product movement, ensure quality and consumer trust.

Error: Contact form not found.

Traceability Solutions

Qodenext offers comprehensive traceability solutions tailored to your specific needs,. Our services leverage cutting-edge RFID technology to provide real-time visibility and control over your assets.

Check out our supply chain traceability solutions to ensure smooth operations and real-time monitoring.

Qodenext’s Commitment to Traceability

Qodenext delivers world-class traceability solutions by leveraging advanced technologies like RFID, automation, and industrial-grade printing.

We implement robust systems that provide full visibility to your supply chain, ensuring every product is tracked with precision and accuracy.

We define traceability to ensure compliance with industry regulations, enhance supply chain efficiency, and building trust by maintaining the integrity of your products from start to finish.

Our solutions are designed to integrate seamlessly into your operations, improving transparency and operational control.

Transform Your Inventory Management

Objectives of Traceability

We provide complete visibility across the entire supply chain. Our customers have the full picture- from raw material sourcing to final delivery.

Ability to meet regulatory requirements by tracking products accurately while maintaining detailed records.

Automation of data collection reduces errors and delays. This ensures seamless tracking throughout the supply chain.

Strengthen consumer confidence by ensuring product authenticity, safety and quality at every stage.

Enhance inventory management and logistics with real-time tracking data that helps prevent bottlenecks and shortages.

Traceability can help identify and recall contaminated or defective products quickly, protecting consumer health.

Traceability ensures authenticity and product quality thus preserving your brand reputation.

Qodenext utilises cutting-edge solutions including RFID technology, IoT devices and data analytics to provide comprehensive traceability.

Qodenext puts data protection first by implementing robust security measures that safeguard sensitive information.

Understanding the traceability meaning, it’s evident that some solutions might need tailoring to meet each client's specific needs and requirements.

It’s crucial to give clients dedicated support and assistance throughout the traceability process.

Transform Your Inventory Management

Unlock Industrial Excellence

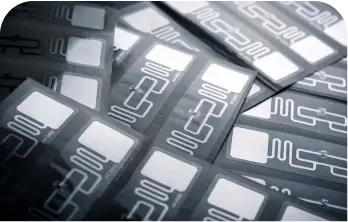

RFID Tags

Radio Frequency Identification or RFID tags are at the core of traceability systems, enabling automated tracking and identification of products across the supply chain.

They offer real-time visibility eliminating manual scrolling, reducing human errors and increasing efficiency.

RFID tags on products can monitor their movement from production to delivery, ensuring accuracy, compliance and security.

Printers

Industrial printers play a vital role in traceability by printing labels and RFID tags. These printers ensure that every product, package, or container carries the necessary identification for tracking purposes.

High-quality printing ensures that barcodes, RFID tags and other traceability marks are durable and readable and even in harsh industrial environments.

Scanning

Barcode and RFID scanners are crucial for reading and capturing traceability data. With industrial-grade scanning devices, operators can quickly access product details, track locations and monitor the supply chain’s status in real-time.

RFID

Apart from tags, RFID being a technology is applicable in a variety of contexts. RFID systems, which include handheld and/or fixed readers, can automate contactless data collection, enhancing the traceability of goods.

Automation

Employing automated analysis systems can minimise human involvement in the processes, accelerate operations, and ensure the data are correctly recorded at every point. It continues to document the location of products in real-time and helps to mitigate delays and inefficiencies along the supply chain.

Inspection (Vision)

Vision systems employ cameras and software to analyze products for quality, defect(s), and compliance. Inspection systems can be used to authenticate products and confirm compliance with desired standards, ensuring complete traceability.

Transform Your Inventory Management

Traceability in Food Industry

Identify the source of food-borne illnesses quickly: Traceability helps users identify the source of the outbreak, thus enabling a rapid response.

Compliance with local, state, and federal food safety regulations: Traceability help users follow food regulations such as HACCP and FSMA.

Support consumer trust: Traceability can demonstrate the safety and quality of the food that is served to consumers.

Benefits of Traceability in Supply Chain

Traceability, the transparency of Drafted in the review process, can rationalize operations by reducing errors and proper allocation of resources as a result.

Traceability will prevent and eliminate probable risks such as product forgery and supply chain interruptions.

Traceability can enhance the customer satisfaction by providing extra information and by ensuring the purity of the product.

Traceability can be unique and the core that distinguishes them from others giving them the best position on the market.

Frequently Asked Questions

What is product traceability?

It refers to tracking and tracing a product through its lifecycle, from production to delivery, by capturing and recording relevant data at every stage of the supply chain.

How does RFID help in traceability?

RFID technology provides automated, contactless tracking, allowing products to be monitored in real time without any need for manual scanning. This increases accuracy and efficiency in data collection.

Why is traceability important in the food industry?

Traceability in the food industry ensures food safety, managing recalls, and maintaining compliance with regulatory standards. This builds consumer trust.