In today’s world where everyone including consumers has heightened environmental awareness, businesses too are turning to sustainability· Sustainability is not only in the products but has also creept into supply chains· If there is an approach that is gaining traction, it is the zero waste packaging. This innovative strategy is unique, it aims to minimise or entirely eliminate waste generation throughout the production, distribution, and consumption processes·

By prioritising materials that are reusable, recyclable, or compostable, supply chains can drastically reduce their environmental footprint. They can do so while simultaneously meeting consumer demand for eco-friendly products·

Sustainable packaging practices are becoming a core component of circular economy initiatives globally. According to the Ellen MacArthur Foundation, adopting circular principles in packaging can reduce waste generation, conserve resources, and lower carbon emissions significantly. [Ellen MacArthur Foundation – Circular Economy](https://ellenmacarthurfoundation.org/circular-economy/overview/concept)”

Eco-friendly packaging solutions do more than benefiting the environment. It also contributes to cost savings and enhanced brand reputation· From utilising biodegradable materials to redesigning packaging for optimal recyclability, companies are exploring various avenues to integrate these solutions into their operations· Let’s see how it helps·

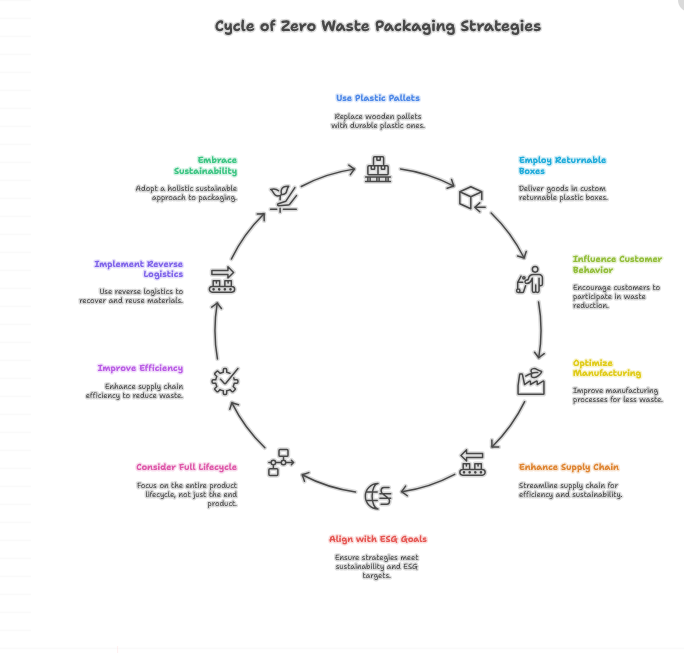

10 Strategies for Zero Waste Packaging

1. Using Plastic Pallets Instead of Wooden Ones

Companies across the world use billions of wood pallets. The Indian market for pallets is expected to reach US$ 3,385.8 Mn by 2033, growing at a ~8.9% CAGR from 2023 to 2033. Wood pallets usually have a lifespan of one year and about half of them are destined for single-use.

The recyclability statistics of wood pallets are somewhat nebulous as some are considered to be ‘recycled”. But the problem arises when you use one pallet more than once. The recyclability statistics of wood pallets becomes doubtful due to the nails and chemicals used in construction.

Another important factor in this is weight. The average weight of a pallet is 40 lb or 18.15 kilograms. This might vastly impact transport energy costs and carbon emissions.

Plastic pallets offer a sustainable alternative to traditional wood pallets, boasting extended lifespans that often surpass 10 years of continuous usage· The longevity of this zero waste packaging not only minimises yearly waste but also eliminates the need for deforestation associated with hardwood pallet production, thereby increasing their value over time·

Typically crafted from recycled plastics, plastic pallets contribute to circularity by being fully recyclable themselves· Furthermore, they provide exceptional strength while simultaneously reducing tare weight and shipping dimensions, thus mitigating the environmental impact caused by carbon emissions from bulky freight transportation·

A prime illustration of plastic pallet efficiency can be observed in lightweight variants, weighing as little as 12 lbs·, which conveniently nest for return shipping and storage purposes.

2. Deliver Goods in Custom Returnable Plastic Boxes

Around the world, multiple governing bodies are banning single-use plastic bags. Even the harvesting, pulping and distribution impacts on paper bags is coming under increased scrutiny. They also have a negative impact on the environment.

These are the reasons why players in the supply chains are turning to zero waste packaging. They are exploring alternative, reusable delivery packaging. Reusable bags are viable for some uses but lack the rigidity and structural strength that can protect fragile items.

But, worry not, there is a solution to this. The solution lies in using corrugated plastic containers. Lightweight and built to last, corrugated plastic boxes, bins, totes and trays make the ideal delivery and distribution packaging solution.Paired with a viable return system, corrugated packaging is the wave of the future.

3. Influence of the Customer

The transformation of consumer goods packaging initiates at the earliest stage of the supply chain: raw material acquisition· Suppliers are now embracing sustainable packaging options for transporting raw materials, aiming to curtail waste and mitigate environmental harm·

This paradigm shift necessitates close collaboration between suppliers and manufacturers to seamlessly integrate zero waste packaging materials· Often, packaging for ingredients and raw materials is single-use, making waste reduction and cost minimization financially prudent·

4. Manufacturing Operations

Within Manufacturing Operations, the adoption of packaging technologies and materials presents both opportunities and obstacles to the manufacturing process· While eco-friendly materials may initially inflate manufacturing costs, ongoing innovations are gradually mitigating these expenses·

Additionally, zero waste packaging design can optimize space utilization, leading to decreased storage and transportation costs· While transitioning to sustainable packaging may demand substantial upfront investment, impacting short-term profitability, the focus should be on the long-term performance of the company·

5. Supply Chain Performance

Supply chain performance is significantly influenced by zero waste shipping packaging changes· Lightweight and compact packaging reduces transportation costs, enabling companies to streamline logistics networks· In some cases, trucks can accommodate increased product volumes·

Moreover, efficient packaging design minimises product damage during transit, thereby enhancing overall supply chain reliability. Real-time tracking technologies facilitate better inventory management, reducing instances of stockouts and wastage.

A study by Ellen MacArthur Foundation shows that redesigning packaging for minimal material use and maximum recyclability can reduce transportation costs by up to 20% and lower CO2 emissions, highlighting measurable business benefits. [Ellen MacArthur Foundation](https://ellenmacarthurfoundation.org/)”

Consumer preferences are also evolving· As consumers become more educated about sustainability and the environment, they want eco-friendly options· There is a growing emphasis on eco-friendliness and aesthetics· Modern consumers are demanding packaging that not only protects the products but also aligns with their values·

This has resulted in manufacturers investing in research and development so that they can create innovative, sustainable and visually appealing packaging solutions·

6. Sustainability and ESG Goals

The global shift towards sustainability and ESG consciousness has reshaped the packaging landscape· Many consumers are not willing to purchase products from manufacturers who do not have the proof to show their carbon footprint or effective ESG measures·

Zero waste packaging is the main motif for this message· Therefore manufacturers are adopting eco-friendly materials like biodegradable plastics, compostable packaging and recycled materials to reduce environmental impact·

Sustainable packaging not only aligns with corporate social responsibility but also meets regulatory requirements and enhances brand reputation·

7. It is More Than the Finished Products

The changes in the consumer good packaging happens at the earliest stage of the supply chain. We are referring to raw material sourcing. Suppliers now use sustainable packaging options for transporting raw materials, reducing waste and minimising environmental harm.

This shift requires the suppliers and manufacturers to collaborate. Only then there can be seamless integration of sustainable packaging materials. In many cases, zero waste packaging for ingredients and raw materials only have single use so there is minimal waste.

8. Enhancing Supply Chain Efficiency

The performance of supply chains and distribution is significantly influenced by alterations in packaging. Adopting lightweight and compact packaging can lead to reduced transportation costs, enabling companies to streamline their logistics networks. In certain instances, this can even allow trucks to accommodate greater product volumes.

Moreover, effective packaging design plays a crucial role in minimising product damage during transit, thereby improving the overall reliability of the supply chain. The integration of real-time tracking technologies facilitates enhanced inventory management, mitigating stockouts and minimising wastage.

9. Unlocking Value through Reverse Logistics

Here are some facts about packaging waste. The implementation of reverse logistics is essential for facilitating reuse. This involves a series of operations aimed at retrieving used products from customers and either disposing of them or preparing them for reuse.

Reverse logistics is one of the best ways to reduce packaging waste. It generates value by transforming waste into sales and fostering customer trust. Businesses engage in reselling, reusing, and recycling returned products. Efficient reverse logistics practices help to keep storage and distribution costs in check while simultaneously reducing a company’s environmental, social, and economic footprint. Furthermore, it can enhance profitability and optimise asset utilisation.

10. Embracing a Sustainable Approach

Combining reduction and reuse strategies and incorporating upcycled or degradable materials represents a forward-thinking approach to maximising impact· Employing tools such as Life Cycle Assessment (LCA) allows for a thorough examination of the expected benefits·

LCA evaluates the entire life cycle of a product, from raw material extraction and processing to manufacturing, distribution, use, and disposal or recycling· By comprehensively analysing resource consumption, energy usage, waste generation, and broader environmental challenges like climate change, LCA enables informed decision-making to minimise a product’s environmental footprint and promote zero waste packaging.

Conclusion

The inclusion of zero waste packaging solutions into supply chains reflects a pivotal shift towards sustainability. At the core of it lies the consumer demand, cost savings, and environmental stewardship. By adopting innovative strategies, collaborating across the supply chain, experts like Qodenext businesses can not only mitigate waste but also unlock value, enhance efficiency, and contribute to a greener future.

FAQs: How Supply Chains Use Zero Waste Packaging Solutions

1. Why is zero waste important in supply chains?

Zero waste in supply chains minimises environmental impact, reduces resource consumption, lowers costs, enhances brand reputation, fosters innovation, and ensures long-term sustainability, aligning with societal and regulatory expectations.

2. What are some examples of zero waste packaging?

Reusable containers, compostable materials, bulk packaging, and minimalist packaging designs are examples of zero waste solutions embraced by supply chains to minimise environmental impact.

3. What are the 5 concepts of zero waste management?

There is an easy to follow guideline on the 5 R’s of Zero Waste Living: Refuse, Reduce, Reuse, Recycle, and Rot.

4. How can companies implement zero waste packaging strategies?

Companies can implement zero waste packaging by:

- Replacing single-use pallets with plastic or reusable alternatives

- Using returnable or reusable delivery containers

- Redesigning packaging to optimize space and minimize materials

- Collaborating with suppliers to integrate sustainable materials

- Implementing reverse logistics to collect and reuse packaging

5. What are the cost advantages of zero waste packaging?

Although the initial investment may be higher, zero waste packaging leads to long-term savings by:

- Reducing packaging waste disposal costs

- Lowering transportation costs with lighter and compact packaging

- Minimizing product damage during transit

- Enhancing brand value and consumer loyalty through sustainability

6. How does reverse logistics support zero waste packaging?

Reverse logistics involves collecting used packaging from customers or retail points and returning it for reuse, recycling, or proper disposal. This process minimizes waste, promotes circular economy practices, and creates value by converting packaging waste into reusable or recyclable assets.

7. Can zero waste packaging improve supply chain efficiency?

Yes. Lightweight, compact, and reusable packaging optimizes storage, reduces transportation costs, and allows for increased product volumes per shipment. Additionally, it minimizes product damage and waste, enhancing overall supply chain reliability and performance.

8. How do consumer preferences influence packaging choices?

Modern consumers prefer eco-friendly, sustainable, and aesthetically appealing packaging. Companies are adapting to these preferences by integrating zero waste materials and designs, which not only satisfy consumer values but also boost brand reputation and loyalty.

9. What is the role of ESG goals in packaging sustainability?

Environmental, Social, and Governance (ESG) goals drive companies to adopt sustainable practices, including zero waste packaging. By demonstrating responsible sourcing, carbon footprint reduction, and waste minimization, companies align with regulatory requirements and consumer expectations, while enhancing corporate reputation.

10. Which industries are leading in zero waste packaging adoption?

Industries at the forefront include:

- E-commerce and retail (Amazon, Flipkart)

- Food and beverage (Nestlé, Unilever)

- Consumer electronics (Apple, Samsung)

- Fast-moving consumer goods (FMCG)

These industries have high packaging volumes and are motivated by environmental impact, cost efficiency, and consumer demand for sustainability.