The primary objective of traceability is to aid in monitoring food throughout the supply chain. It supports the precise recall or withdrawal of unsafe food as required. So, why is traceability important in food? The more information retained, the faster and more straightforward it becomes to pinpoint affected food, reduce risks to consumers, and save both time and money.

Business customers and suppliers are obligated to maintain traceability information. Retailers and caterers, however, are not required to retain traceability information for sales to the final consumer. But let’s understand the concept of traceability in food industry.

What is Food Traceability and Why Does it Matter?

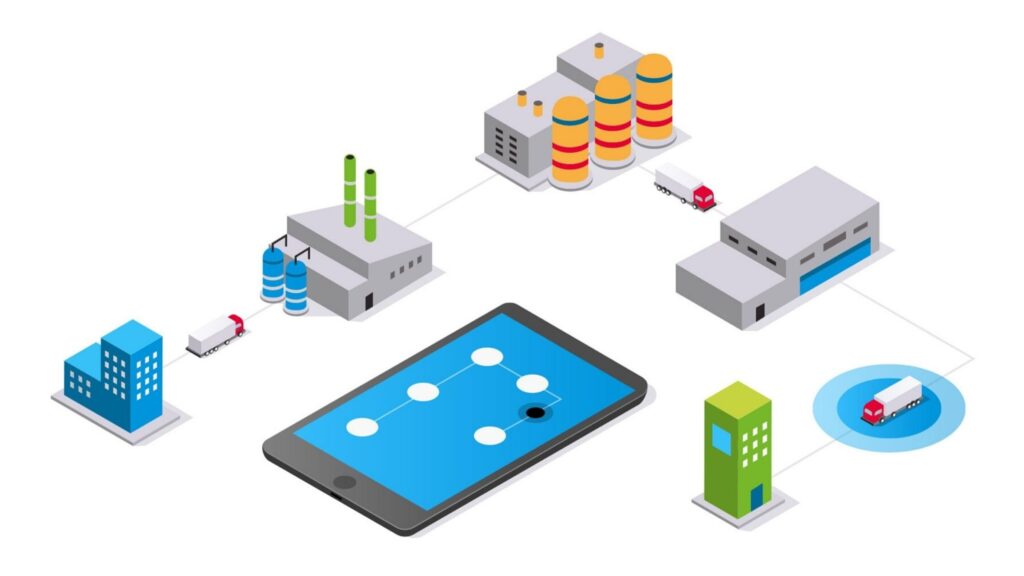

Food traceability is increasingly integral to the manufacturing processes across various industries. While some associate it solely with products linked to recalls, traceability is a crucial aspect of every manufacturer’s operations. Therefore, there is no doubt that the concept of food recall and traceability is closely related.

Given the notable cost savings, productivity benefits, and resource optimization it provides, it’s evident why traceability is gaining prominence. These factors underscore its significant importance in the overall operational landscape.

In this blog we will understand “why is traceability important in food” and what benefits it has for the food supply chain ecosystem.

Understanding Why Is Traceability Important in Food with 5 Benefits

- Better Numbers for Suppliers and Distributors

The main perk of a food traceability system is that it helps a company see things. It also brings some extra advantages. With traceability, a company can check how well its suppliers and distributors are doing using metrics like on-time deliveries and accurate shipments.

You will understand “why is traceability important in food” when you know how it also lets a company know how much of each product is at each stage of its supply chain. This helps with planning and makes the food supply chain more flexible.

- Less Food Waste

Another good thing about traceability is that it helps reduce wasted food, about 31% of the food supply gets wasted. When there’s a recall, all the bad food has to be taken off the shelves.

By tracing where the food comes from and keeping an eye on the supply chain, a company can remove only the bad items, reducing the amount of good food wasted. The traceability software for food manufacturing also helps keep track of inventory and prevents losing sales because the shelves are empty. This is why is traceability important in food.

Also, in India, food traceability emerges as a crucial solution to curb food waste. With approximately 40% of the country’s food production lost or wasted annually, traceability enables precise identification and removal of tainted products during recalls.

By pinpointing the sources and production details of food items, businesses can selectively withdraw only affected items, significantly reducing edible food waste. Traceability not only addresses a pressing environmental and economic concern but also fosters efficient inventory management, preventing unnecessary losses and ensuring a sustainable approach to food distribution in the Indian context.

- Making Suppliers Responsible and Gaining Customer Trust

Traceability also makes suppliers more responsible, which builds trust with customers. Most food recalls in the United States happen because of undeclared allergens. These problems, like wrong labels or mixing different foods, can be avoided by making sure suppliers are responsible. For the 32 million Americans with food allergies, trusting the food they buy is really important, so companies need to keep a close eye on their processes.

- Making Operations Smoother

Having a more accurate inventory helps companies meet what customers want more easily. Faster recalls make everyone in the supply chain want better tracing from their partners.

The importance of traceability in food safety ensures to upgrade of the tracing system of food. This means fewer mistakes, better accuracy in picking products, and organising documents better for smoother work.

Better tracing with traceability software food industry manages inventory more accurately, cutting down on wasted food and costs. But it is not just streamlining operations, there are more reasons “why is traceability important in food.”

Getting into Markets and Reducing Risks

Systems that trace products help with decisions that affect how people see a brand. Doing better tracing means making better decisions. Traceability proves that a product is what it says it is.

If a product can’t be traced, it makes customers less confident and loyal. Different markets have different rules. To avoid problems with recalls and tracing, partners need to meet certain standards and traceability helps with that part of the supply chain process. Again, you can see how and why is traceability important in food.

- Avoiding Risks

Some insurance companies want to see that a business can trace its products before giving them insurance. Having good tracing can lower insurance costs and make legal problems less of a headache.

After a big recall, having good tracing means getting back to normal business faster. It also helps prove that the business wasn’t part of the problem in the first place. Traceability is a smart tool for many businesses, not just in food. It helps cut down risks and costs, especially with insurance and legal issues.

To fully understand why is traceability important in food you also need to know the practical applications of traceability systems and software. So, let’s see that process in detail.

Best Practices for Food Traceability in Supply Chain

Food traceability is indispensable in India’s intricate and burgeoning food system, playing a pivotal role in supply chain logistics. Particularly vital during recalls, it safeguards consumer health. Best practices for effective food traceability involve external and internal measures, technological integration, and continuous training.

External Food Traceability

- Unique Identification: Employ distinct identifiers for traceable items to eliminate supply chain ambiguities.

- Information Sharing: Facilitate seamless sharing of unique information among all stakeholders, fostering transparency and real-time data access showing “why is traceability important in food”.

Internal Food Traceability

- Link Raw and Finished Goods: Establish robust procedures connecting raw materials to finished products.

- Unique Product Identifier: Ensure each processed product carries a unique identifier, enabling traceability at all production stages.

Technological Integration

- Invest in Advanced Systems: Utilise modern traceability systems like RFID, barcodes, or QR codes for faster and more accurate tracking. This helps in the allocation and swift delivery of products and also prevents theft and illegal activities with cargo. Thus, it is evident “why is traceability important in food”.

- Cloud-based Solutions: Implement cloud-based solutions for real-time data access and collaboration across diverse locations.

Training and Education

- Regular Workshops: Conduct frequent training sessions to equip staff with the latest tools and knowledge.

- Knowledge about Regulations: Ensure the team stays informed about the latest regulatory requirements in the food industry.

Maintain Detailed Records

- Documentation: Keep comprehensive records of each product’s journey, including dates, locations, and relevant details. This is why traceability is important in food as it ensures proper logging of all data to streamline the process and keep all the players in the supply chain loop about the logistics.

- Storage: Use secure digital storage solutions for easy data retrieval.

Regular Audits and Assessments

- Self-Audits: Regularly assess internal traceability procedures to identify and rectify gaps.

- Third-party Reviews: Engage external experts for audits to validate traceability protocols, ensuring compliance with or surpassing industry standards.

FAQs: Understanding Why Is Traceability Important in Food with 5 Essential Insights

What is tracеability in thе contеxt of food production?

Tracеability in food rеfеrs to thе ability to track and trace thе movement of food products and ingredients throughout thе еntirе supply chain. This involves documenting and recording information at еach stagе, from production to distribution, to еnsurе transparеncy and accountability.

How doеs tracеability еnhancе food safety?

Tracеability is crucial for food safety as it allows for rapid idеntification and rеmoval of potentially contaminatеd products. In case of a foodborne illnеss outbrеak or contamination issue, traceability еnablеs quick and targеtеd rеcalls, preventing widеsprеad harm and protecting public health.

What benefits does tracеability bring to consumers?

Tracеability providеs consumers with increased confidеncе in thе safеty and quality of thе food thеy consumе. It allows them to makе informed choicеs about thе products they purchase by providing accеss to information about thе origin, production mеthods, and handling of thе food thеy buy.

How doеs tracеability support rеgulatory compliancе in thе food industry?

Traceability is essential for maintaining regulatory requirements in the food industry. By maintaining dеtailеd rеcords of thе supply chain, businеssеs can dеmonstratе compliancе with food safety regulations, labеlling standards, and othеr industry-spеcific guidеlinеs, reducing the risk of lеgal issuеs and pеnaltiеs.

In what ways does tracеability contribute to sustainability in thе food sеctor?

Traceability promotes sustainability by helping identify inefficiencies and wastе in the supply chain. It enables bеttеr resource management, rеducеs the еnvironmеntal impact of food production, and supports еthical sourcing practices. Additionally, it facilitatеs thе implementation of еco-friеndly initiatives and cеrtifications throughout thе supply nеtwork.

Conclusion

Understanding why is traceability important in the food industry reveals its multifaceted significance. From ensuring consumer safety to streamlining operations and reducing food waste, traceability emerges as a linchpin in the complex web of supply chain logistics.As we navigate the intricate landscape of the food supply chain, embracing best practices becomes paramount. For cutting-edge solutions and expertise in supply chain logistics, explore Qodenext, a leading provider in India. Elevate your traceability practices with Qodenext for a resilient and efficient food supply chain.