Procurement is a critical business function that ensures organizations acquire the necessary goods, services, and resources to operate efficiently. From sourcing raw materials to negotiating contracts, procurement plays a key role in managing costs, ensuring quality, and maintaining supplier relationships.

In this comprehensive guide, we will explore what is procurement process, its various types, benefits, and key steps. By the end, you’ll have a clear understanding of how procurement impacts business success and operational efficiency.

Understanding what is the Procurement Process

Before diving into the details, let’s first define what is procurement process.

The procurement definition refers to the structured approach a business follows to acquire goods, services, or works from external sources. It involves identifying needs, evaluating suppliers, negotiating contracts, placing orders, and managing supplier relationships.

This process is essential for organizations to ensure they procure high-quality products at the best possible price while maintaining compliance with legal and ethical standards.

Types of Procurement Process

Procurement can be classified into different types based on business needs and sourcing strategies. Here are the four major types:

1. Direct Procurement

Definition:

This involves purchasing raw materials, components, or goods that are directly used in the production or delivery of a company’s core products or services.

Purpose:

To ensure consistent supply for manufacturing and production activities.

Examples:

Steel for car production, fabric for clothing manufacturing, or ingredients for food processing.

2. Indirect Procurement

Definition:

Refers to acquiring goods and services not directly linked to the production process but critical for daily operations and support functions.

Purpose:

To maintain business functions like IT, administration, and facilities.

Examples:

Office supplies, marketing services, IT software, and maintenance services.

3. Goods Procurement

Definition:

Focuses on purchasing physical items—whether raw materials, machinery, tools, or finished goods needed for business operations.

Purpose:

To acquire the tangible assets needed for production or sale.

Examples:

Equipment, vehicles, packaging materials, inventory for resale.

4. Services Procurement

Definition:

Involves sourcing intangible offerings and expertise that provide support or specialized services to the organization.

Purpose:

To fulfill requirements that cannot be met internally and require third-party service providers.

Examples:

Consulting, legal services, logistics, software development, or cleaning services.

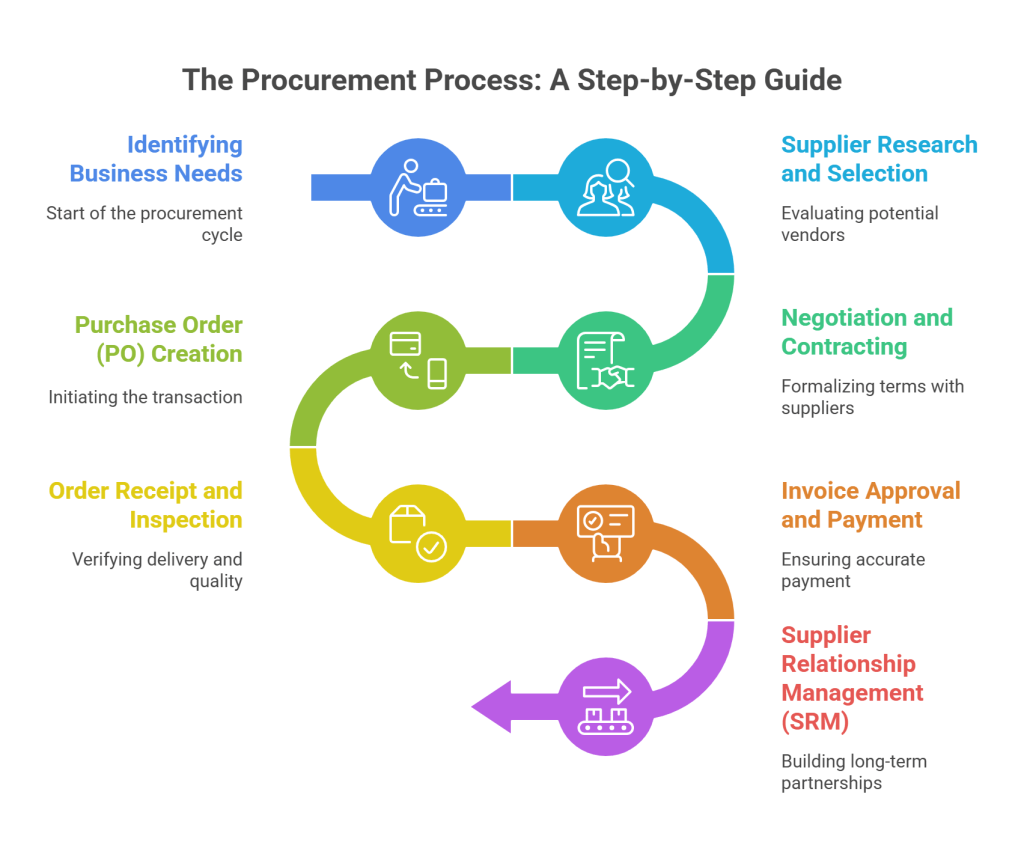

Key Steps in the Procurement Process

The procurement process is a strategic function that ensures an organization efficiently acquires the goods and services it needs to operate. A well-defined procurement process not only controls costs but also enhances operational efficiency and supplier collaboration. Below are the seven key steps involved in the procurement cycle, explained in greater detail:

1. Identifying Business Needs

What It Entails:

The procurement process starts when a department or team identifies a requirement for goods, services, or materials. This need can stem from multiple triggers, such as low stock levels, expanded production plans, new project launches, or equipment upgrades.

Key Considerations:

- Is the need recurring or one-time?

- What are the quantity, specifications, and timeline?

- Are there internal alternatives or contracts already in place?

Why It Matters:

Accurate identification of needs ensures that procurement efforts are focused, budget-aligned, and timely—preventing rushed purchases or disruptions in operations.

2. Supplier Research and Selection

What It Entails:

Once the requirement is defined, procurement teams conduct market research to identify possible vendors. Suppliers are evaluated on criteria such as price competitiveness, quality standards, reliability, capacity, delivery timelines, reputation, and compliance.

Tools and Activities:

- Request for Proposal (RFP)

- Request for Quotation (RFQ)

- Invitations to Tender (ITT)

- Supplier audits and shortlisting

Why It Matters:

Choosing the right supplier prevents future risks related to delays, quality issues, inflated costs, or contractual breaches.

3. Negotiation and Contracting

What It Entails:

After a supplier is selected, both parties engage in negotiations regarding pricing, delivery terms, warranties, penalties, and terms of service. Once mutually agreeable, these terms are formalized in a legally binding contract.

Key Contract Elements:

- Pricing model (fixed, per unit, volume-based)

- Payment terms and conditions

- Delivery schedules and fulfillment obligations

- Confidentiality, liability, and dispute resolution clauses

Why It Matters:

Clear contract documentation protects both parties, aligns expectations, and lays the foundation for performance monitoring.

4. Purchase Order (PO) Creation

What It Entails:

With the contract in place, the organization issues a Purchase Order (PO) to initiate the transaction. The PO details the product or service being ordered, the quantity, agreed price, delivery instructions, and reference to the contract.

Key Components of a PO:

- PO number and date

- Vendor name and address

- Description of items/services

- Payment and shipping terms

Why It Matters:

The PO serves as an official internal and supplier-facing document that authorizes procurement and facilitates invoicing and delivery tracking.

5. Order Receipt and Inspection

What It Entails:

Upon delivery, goods or services are inspected to verify they meet the requirements as per the PO and contract. Where applicable, acceptance testing, quality control, or compliance reporting is conducted.

Verification Checks:

- Quantity of items received

- Product quality, functionality, and compliance with specification

- Damaged or incomplete shipments

- Timeliness of delivery

Why It Matters:

This step protects the company from paying for defective or incomplete goods and ensures that materials are ready for use or further processing without delay.

6. Invoice Approval and Payment

What It Entails:

Following successful delivery and inspection, the supplier sends an invoice that corresponds to the terms outlined in the PO. The procurement or finance team cross-checks the invoice against the PO and receipt report before authorizing payment.

Steps Involved:

- 3-way matching: Invoice + PO + Goods Receipt

- Dispute resolution (if invoicing discrepancies arise)

- Issuing payment according to agreed terms (e.g., Net 30, Net 60)

Why It Matters:

Proper invoice verification ensures payment accuracy, builds supplier trust, prevents overcharging, and keeps the financial records clean.

7. Supplier Relationship Management (SRM)

What It Entails:

Procurement doesn’t end with payment. Maintaining long-term, value-driven relationships with reliable suppliers is key for sustainable operations. SRM involves periodic performance evaluations, feedback sessions, collaboration on innovation, and resolving service issues.

Performance Indicators:

- Timely delivery rates

- Quality and compliance reports

- Responsiveness and communication

- Cost-effectiveness

Why It Matters:

Strong supplier relationships lead to better contract rates, collaborative product development, faster issue resolution, and preferred access during market shortages or crises.

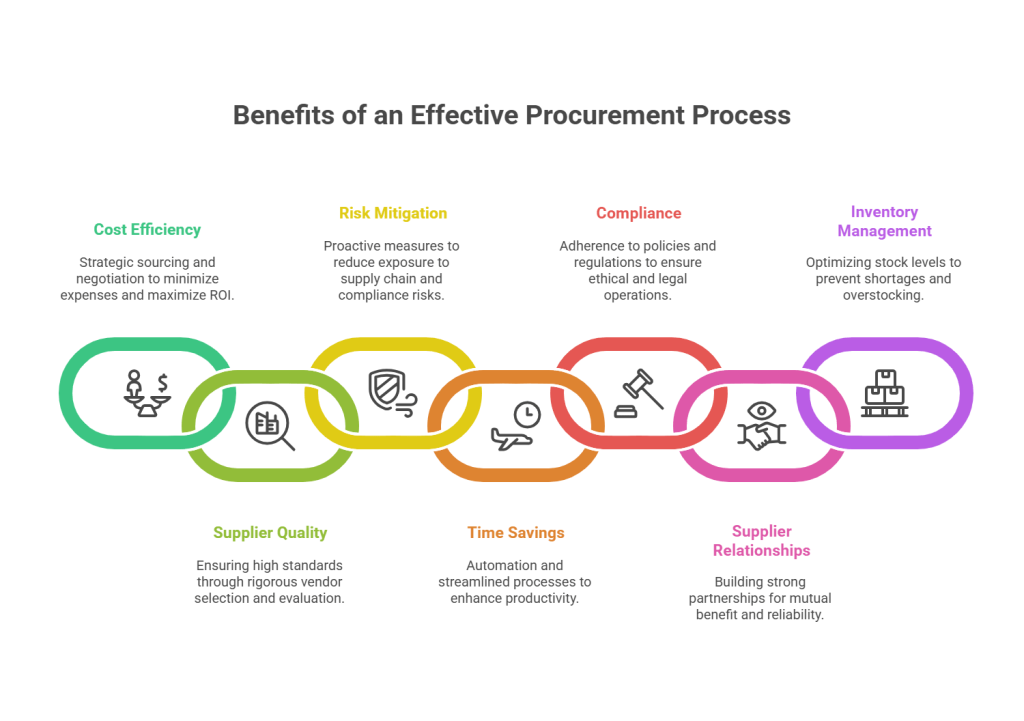

Benefits of an Effective Procurement Process

A well-managed procurement function does far more than just purchasing—it plays a vital role in cost control, operational efficiency, risk reduction, and strategic growth. Below are the key benefits of establishing and maintaining a structured procurement process:

1. Cost Efficiency

Effective procurement strategies allow businesses to identify the best price-value combinations through competitive bidding, supplier negotiation, and volume purchasing. By securing favorable contract terms and avoiding overpayments, companies significantly cut down procurement and operational costs. Strategic sourcing also helps in minimizing wasteful spending and enhancing return on investment.

2. Improved Supplier Quality

A robust procurement process emphasizes supplier evaluation and selection based on strict quality criteria. This ensures that only reliable and high-performing vendors are engaged. Sourcing quality materials or services leads to fewer defects, reduced rework, and higher levels of output efficiency—ultimately benefiting product quality and customer satisfaction.

3. Risk Mitigation

Structured procurement helps organizations limit exposure to risks such as:

- Late or missed deliveries

- Substandard goods

- Price volatility

- Supplier failures

- Regulatory non-compliance

By implementing pre-qualification checks, contract controls, and performance tracking, businesses can proactively manage and reduce these risks, protecting both reputation and profitability.

4. Time Savings and Enhanced Productivity

Modern procurement systems are supported by automation tools like e-procurement platforms and ERP integrations. These systems accelerate purchase requisitions, approvals, and vendor communications, reducing reliance on manual paperwork. Teams can redirect their time from transactional tasks toward value-adding functions such as supplier development, market analysis, or cost forecasting.

5. Enhanced Compliance and Transparency

A formalized procurement process ensures all purchases comply with internal policies, ethical standards, and legal regulations. Transparent procedures offer a clear audit trail for each transaction, reducing the risk of fraud, corruption, or unauthorized spending. This is particularly important in regulated industries and for companies undergoing audits or certifications.

6. Stronger Supplier Relationships

Effective procurement is not a one-time activity but an ongoing relationship. Consistent communication, timely payments, fair treatment, and collaborative planning foster stronger partnerships with suppliers. These relationships lead to better pricing, preferential treatment, innovation sharing, and dependable service—especially during critical times like supply chain disruptions or increased demand.

7. Better Inventory Management

Procurement plays a critical role in ensuring the right quantity of goods is ordered and delivered at the right time. Timely replenishment avoids inventory shortages that can halt production, and prevents overstocking that ties up capital and storage space. This balance improves warehouse efficiency, lowers carrying costs, and enhances cash flow.

Challenges in the Procurement Department

Despite its benefits, procurement comes with challenges that organizations must navigate:

- Supplier Reliability Issues – Delays or quality concerns can disrupt business operations.

- Cost Fluctuations – Price changes due to market conditions can impact procurement budgets.

- Compliance Risks – Failure to adhere to regulations can result in penalties and reputational damage.

- Lack of Automation – Manual procurement processes lead to inefficiencies and errors.

- Poor Communication – Misalignment between departments and suppliers can cause operational issues.

To overcome these challenges, businesses adopt e-procurement systems, supplier management tools, and strategic sourcing practices.

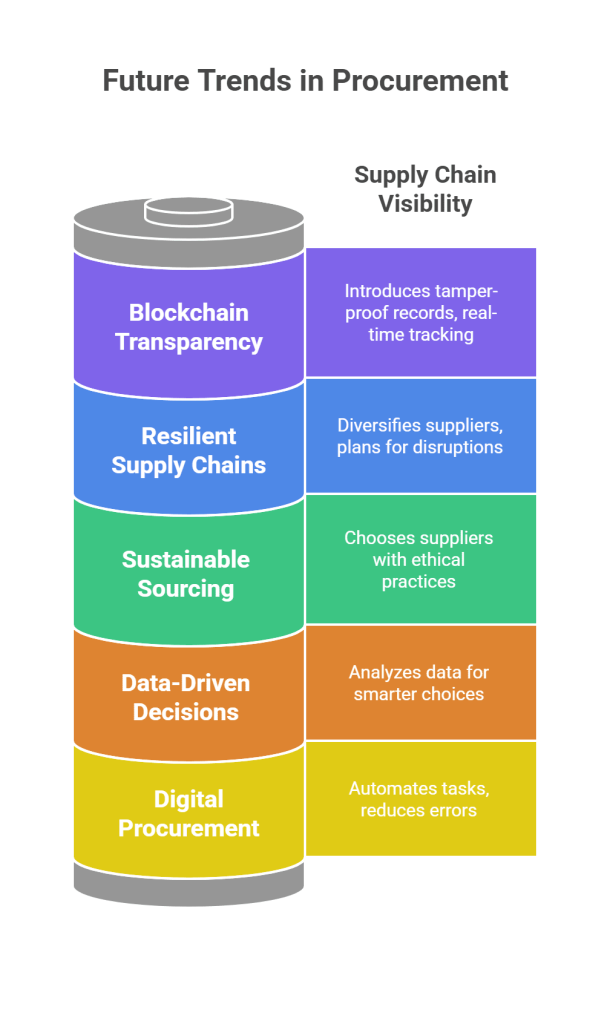

Future Trends in Procurement

As businesses modernize and global supply chains become more complex, procurement practices are advancing rapidly. The following key trends are shaping the future of procurement, driving efficiency, transparency, and sustainability across organizations:

1. Digital Procurement and Automation

- AI-powered procurement platforms are transforming traditional processes by automating repetitive tasks such as supplier selection, contract management, and invoice processing.

- These platforms reduce human errors, increase transaction speeds, and enable seamless integration with other business systems.

- Automation frees up procurement teams to focus on strategic initiatives like supplier development and risk assessment.

2. Sustainable and Ethical Sourcing

- Companies are increasingly choosing suppliers who demonstrate sustainable practices—such as minimal environmental impact, reduced carbon emissions, and responsible resource use.

- Ethical sourcing means vetting suppliers for compliance with labor regulations, fair wages, and safe working conditions.

- Procurement teams now factor in environmental and social governance (ESG) metrics when assessing supplier performance and long-term partnerships.

3. Blockchain for Transparency

- Blockchain technology introduces tamper-proof records and real-time tracking throughout the supply chain.

- It enables all parties to access a shared ledger, making it easier to verify product origins, ensure responsible sourcing, and prevent fraud.

- Blockchain increases trust among supply chain partners and supports compliance with regulatory requirements.

4. Data-Driven Decision Making

- Procurement processes are becoming more analytical with the adoption of big data and advanced analytics.

- Tools analyze historical spend, supplier performance, and market trends to support smarter purchasing decisions and risk forecasting.

- Data-driven insights also facilitate dynamic supplier segmentation, performance evaluations, and continuous process improvement.

5. Building Resilient Supply Chains

Scenario planning and risk modeling are now standard practices to ensure business continuity during events like natural disasters, pandemics, or geopolitical tensions.

Recent global disruptions have underscored the importance of robust supply chains.

Organizations are diversifying their supplier base, exploring nearshoring or local sourcing options, and developing contingency plans.

Conclusion

Understanding what is procurement process is crucial for businesses aiming to optimize costs, enhance supplier management, and ensure seamless operations. A well-structured procurement process contributes to efficiency, transparency, and long-term growth.

By leveraging technology, focusing on supplier relationships, and implementing best practices, businesses can navigate procurement challenges and stay ahead in an evolving marketplace.

Want to invest in a robust supply chain strategy, contact Qodenext today.

Now, let’s understand what is the procurement process under the FAQs section.

FAQs – What is the Procurement Process?

1. What is procurement in the supply chain?

Procurement is the structured process of acquiring goods, services, or works from external sources to meet business needs efficiently.

2. What are the main types of procurement?

We’ve already mentioned the major procurement types which include direct, indirect, goods, and services.

3. Why is procurement important for businesses?

Procurement ensures cost savings, quality assurance, risk management, and operational efficiency, making it vital for business success.

4. How does procurement differ from purchasing?

Procurement is a broader process involving supplier selection, negotiation, and contract management while purchasing refers to the act of buying goods or services.

5. What technologies are transforming procurement?

AI, blockchain, e-procurement software, and data analytics are revolutionizing procurement by improving efficiency and transparency.

6. How can businesses improve their procurement process?

Organizations can enhance procurement by automating workflows, evaluating suppliers effectively, negotiating better contracts, and adopting sustainable sourcing strategies.

7. What are the risks in procurement?

Common risks include supplier delays, cost fluctuations, compliance issues, fraud, and lack of transparency in supplier relationships.