In the world of manufacturing and product development, PDM and PLM are two acronyms that hold significant importance. Product Data Management (PDM) refers to the software and tools used to manage and track product data throughout its lifecycle. On the other hand, Product Lifecycle Management (PLM) is a broader approach that includes PDM and focuses on managing the entire lifecycle of a product, from ideation to disposal.

Effective PDM and PLM processes can have a significant impact on inventory control. By managing product data and lifecycle information effectively, companies can improve their inventory control system, reduce the risk of overstocking or understocking products, streamline the production process, and ensure that inventory levels are always optimized. In this blog, we shall dive deeper into PDM and PLM and explore their impact on inventory control models in detail.

What Is PDM and PLM? How It Impacts Inventory Control?

What is PLM?

PLM (Product Lifecycle Management) stands for Product Lifecycle Management, which is a systematic approach used by businesses to manage the entire lifecycle of their products, from ideation and design to manufacturing, distribution, and end-of-life disposal. PLM integrates people, processes, and technology to facilitate collaboration, improve communication, and streamline workflows across different departments and stakeholders involved in product development and delivery. Here are some of the benefits of implementing a PLM system:

Improved Product Quality:

PLM allows businesses to manage product data and requirements, enabling better collaboration and visibility throughout the product lifecycle. This leads to better quality products, reducing errors, rework, and delays.

Faster Time-to-Market:

PLM helps businesses to manage and streamline product development processes, reducing time-to-market and improving competitiveness.

Reduced Costs:

PLM helps businesses to optimize their product development processes, reducing waste, errors, and duplication. This leads to lower costs and improved profitability.

Better Compliance:

PLM helps businesses to manage compliance requirements, such as safety, environmental, and regulatory standards. By ensuring compliance, businesses can reduce the risk of legal issues and protect their reputation.

Enhanced Innovation:

PLM facilitates innovation by enabling businesses to capture and manage new ideas, analyze customer feedback, and incorporate market trends. This leads to improved products and increased customer satisfaction.

Improved Customer Experience:

PLM enables businesses to understand and respond to customer needs better, ensuring that products meet their expectations. This leads to increased customer loyalty and improved brand reputation.

Overall, PLM provides a strategic framework that enables businesses to manage their product development processes effectively, improving quality, reducing costs, and enhancing competitiveness.

What is PDM?

PDM (Product Data Management) stands for Product Data Management, which is a software-based solution that helps organizations manage and centralize their product-related data and information throughout the entire product lifecycle. This includes everything from design and development to production and maintenance. Here are some of the benefits of implementing a PDM system:

Improved data organization and accessibility:

PDM software allows companies to store and manage product data in a centralized location, making it easy to find and access when needed.

Enhanced collaboration:

With PDM, team members can access and share the same product data, reducing the risk of errors and inconsistencies.

Increased productivity:

PDM systems automate many manual tasks such as version control, change management, and approval processes, allowing teams to focus on higher-value tasks.

Improved product quality:

By providing a single source of truth for product data, PDM ensures that teams are working with the most up-to-date and accurate information, reducing the risk of errors and improving product quality.

Streamlined regulatory compliance:

PDM solutions can help companies meet regulatory compliance requirements by tracking and documenting product data changes and approvals.

Better decision-making:

With PDM, companies can access real-time data and analytics on product development and performance, enabling better decision-making and more informed business strategies.

Overall, PDM solutions provide organizations with a centralized, streamlined approach to managing product data throughout the entire product lifecycle, leading to improved collaboration, productivity, quality, compliance, and decision-making.

PDM vs PLM: Key Differences between Them

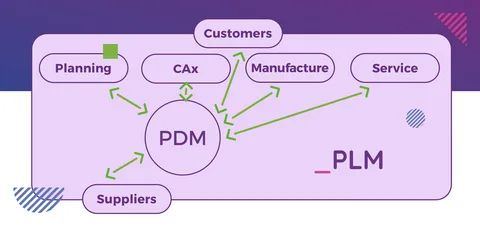

Product Data Management (PDM) and Product Lifecycle Management (PLM) are two software systems that are widely used in manufacturing industries. While they share some similarities, there are significant differences between them.

PDM is primarily concerned with managing data related to product development and design. It focuses on creating a centralized repository of product data such as bills of materials, engineering change orders, and CAD files. The goal of PDM is to ensure that everyone involved in product development has access to the most up-to-date and accurate data.

PDM systems, such as PDM Software, are typically used by engineering teams and may integrate with other tools such as computer-aided design (CAD) software. PLM, on the other hand, is a broader system that manages the entire lifecycle of a product, from ideation to retirement.

It includes PDM functionality but also covers areas such as project management, supply chain management, quality management, and regulatory compliance. PLM systems, like PLM Software, are used by various teams across an organization, including engineering, manufacturing, marketing, and sales.

Key Differences between PDM and PLM:

- Scope: PDM is focused on managing product data related to design and development, while PLM covers the entire product lifecycle from concept to end-of-life.

- Integration: PDM systems are often integrated with CAD tools and other engineering software, while PLM systems may integrate with a broader range of enterprise applications such as enterprise resource planning (ERP) and customer relationship management (CRM) systems.

- Collaboration: While PDM systems focus on collaboration within engineering teams, PLM systems support collaboration across multiple teams and departments.

- Functionality: PDM systems typically provide basic version control and document management capabilities, while PLM systems offer more advanced functionality such as project management, supply chain management, and compliance management.

- Timeframe: PDM systems are focused on managing data in the short term, such as during the design and development phase of a product. In contrast, PLM systems are designed to manage data over a longer timeframe, such as the entire lifecycle of a product.

- Cost: PDM systems are generally less expensive than PLM systems, as they are more narrowly focused and have fewer features. PLM systems are typically more expensive because they are designed to support a broader range of functions and are used by more teams across an organization.

Overall, companies should carefully consider their budget and specific needs when choosing between PDM and PLM systems. PDM may be a good option for smaller organizations or those with limited budgets, while PLM may be a better choice for larger companies that require a comprehensive approach to managing their product lifecycles.

How PDM and PLM Impact Inventory Control?

PDM (Product Data Management) and PLM (Product Lifecycle Management) are software tools used to manage product data and the entire lifecycle of a product, from its conception to its retirement. These tools can have a significant impact on inventory control by improving the inventory control system, reducing inventory costs, and optimizing the inventory management process. Here are some ways in which PDM and PLM impact inventory control:

Improved Inventory Accuracy:

PDM and PLM provide a centralized database for product data, including bills of materials (BOMs), which contain detailed information on the components and parts required to manufacture a product. By using accurate BOMs, manufacturers can improve the accuracy of their inventory data and reduce the risk of stockouts or excess inventory.

Better Forecasting:

PDM and PLM provide manufacturers with a comprehensive view of their product data, including historical sales data and demand forecasts. By using this information, manufacturers can better predict demand and adjust their inventory levels accordingly, reducing the risk of stockouts or overstocking.

Faster Time to Market:

PDM and PLM can help manufacturers streamline their product development process, reducing the time it takes to bring new products to market. This can have a positive impact on inventory control by reducing the risk of excess inventory for products that are slow to sell.

Cost Savings:

PDM and PLM can help manufacturers reduce costs by optimizing their inventory management process. By improving inventory accuracy and demand forecasting, manufacturers can reduce the risk of stockouts and overstocking, which can lead to excess inventory and associated costs.

Enhanced Collaboration:

PDM and PLM provide a platform for collaboration between different departments involved in the product development process. This can help manufacturers improve communication and coordination, which can lead to better inventory control.

Overall, PDM and PLM can have a significant impact on inventory control by improving inventory accuracy, reducing costs, and optimizing the inventory management process. By utilizing PDM and PLM, manufacturers can enhance their inventory control system, reduce the risk of stockouts and excess inventory, and ultimately improve their bottom line.

Conclusion

PDM and PLM are important tools for managing product data and lifecycles. They help businesses optimize inventory control, reduce errors, and improve collaboration. Implementing PDM and PLM can streamline processes and provide a centralized platform for managing product information.

Qodenext’s SETU offers an integrated PDM and PLM solution that can help businesses enhance their inventory control and streamline operations. With SETU, businesses can benefit from real-time inventory tracking, better collaboration, and improved decision-making. Contact Qodenext today to learn more about how the solution can benefit your business.