In today’s hyper-competitive market landscape, businesses must strike a delicate balance between meeting customer demands and keeping inventory costs under control. Overstocking leads to wasted capital and storage costs, while understocking results in lost sales and poor customer experiences. To solve this dilemma, many forward-thinking companies are turning to a powerful solution: the inventory optimisation model.

This data-driven framework goes beyond traditional inventory management by leveraging advanced analytics and, more recently, machine learning to fine-tune inventory decisions. Let’s delve deeper into what an inventory efficiency model is, how machine learning enhances its capabilities, and why it’s rapidly becoming a necessity in modern supply chains.

Understanding the Inventory Optimisation Model

An inventory optimisation model is a systematic approach used to determine the ideal quantity and timing of stock replenishments. It takes into account various factors like demand variability, lead times, service levels, holding costs, and order costs to maintain optimal stock levels across multiple products and locations.

Traditionally, such models were built using deterministic methods such as the Economic Order Quantity (EOQ) and reorder point formulas. However, modern inventory optimisation models often incorporate stochastic elements to handle uncertainties in demand and supply. This shift enables more realistic and adaptive inventory policies.

Key Components of an Inventory Optimisation Model

To function effectively, an inventory optimization model integrates several core components:

- Demand Forecasting: Accurate prediction of future product demand using historical sales data.

- Lead Time Analysis: Analysing the time required to predict inventory trends.

- Cost Balancing: Evaluating trade-offs between holding, shortage, and ordering costs.

- Service Level Targets: Setting goals to meet customer expectations without overstocking.

- Multi-Echelon Planning: Coordinating inventory decisions across suppliers, warehouses, and retail outlets.

Each of these components feeds into the model to help generate optimal inventory decisions tailored to business goals.

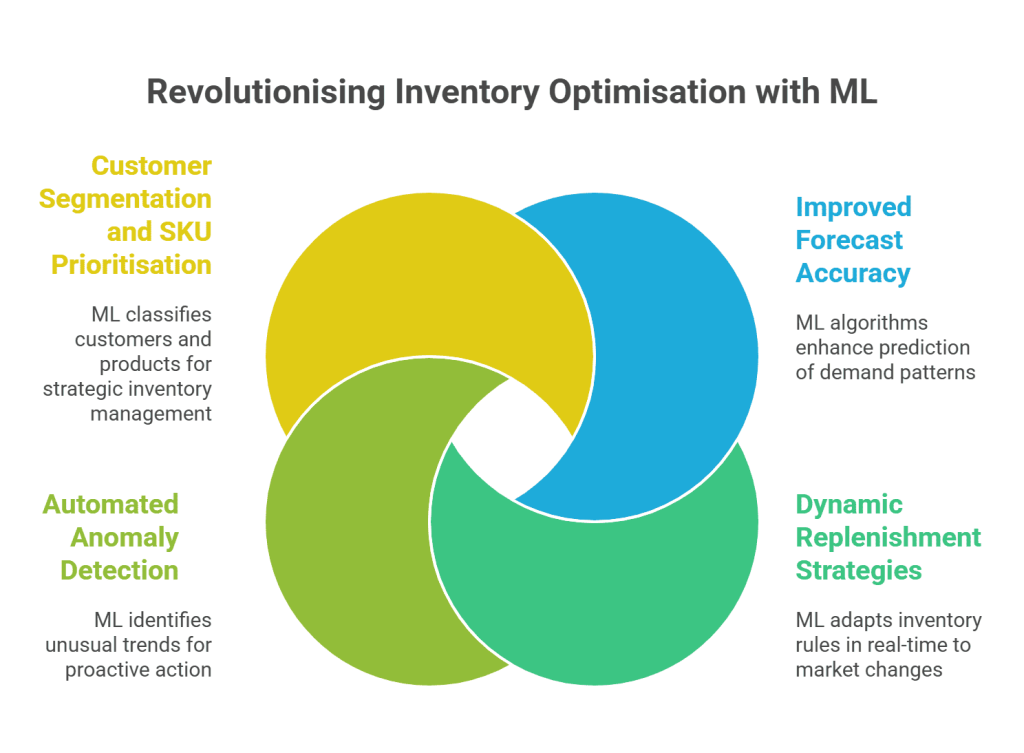

Why Machine Learning is Revolutionizing Inventory Optimization

While traditional models offer value, they fall short when dealing with complex, non-linear, or highly volatile environments. That’s where machine learning (ML) comes in. ML algorithms excel at identifying hidden patterns in vast datasets, enabling smarter and more adaptive decision-making.

1. Improved Forecast Accuracy

Machine learning algorithms such as ARIMA, XGBoost, and LSTM neural networks are capable of capturing seasonality, trends, and outliers far better than rule-based systems.

2. Dynamic Replenishment Strategies

ML can continuously learn from data and update inventory rules in real-time. For instance, if customer buying behaviour changes due to a market event, the ML-enhanced optimisation model can quickly adapt, minimising disruptions.

3. Automated Anomaly Detection

Machine learning models can spot unusual trends, like sudden drops or spikes in demand, that would go unnoticed by conventional systems. By flagging these anomalies, the model allows businesses to act proactively rather than reactively.

4. Customer Segmentation and SKU Prioritisation

ML helps classify customers and products based on profitability, frequency of sales, and forecast variability. This allows the inventory optimisation model to prioritise critical SKUs and manage inventory more strategically.

Real-World Applications of Machine Learning in Inventory Optimisation

Many industries are already seeing the benefits of applying machine learning to inventory management:

- Retail: Global retail chains use ML-powered optimisation models to maintain just-in-time stock levels across thousands of stores, reducing overstock and markdowns.

- Manufacturing: Machine learning forecasts raw material needs and manages parts inventory in complex production environments.

- Pharmaceuticals: ML helps maintain compliance by ensuring temperature-sensitive drugs are replenished on time.

- E-commerce: Real-time demand sensing using ML ensures rapid fulfilment and reduces stockouts during flash sales or seasonal spikes.

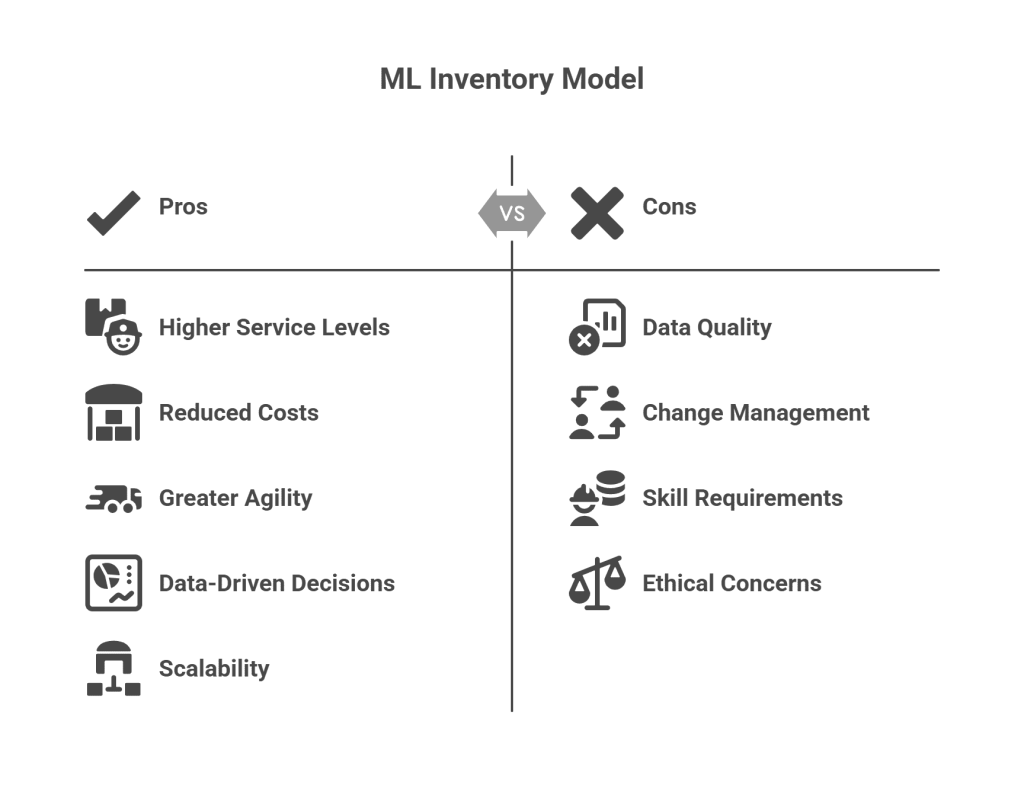

Benefits of Using a Machine Learning-Based Inventory Optimisation Model

The integration of machine learning provides tangible advantages that traditional models simply cannot match:

- Higher Service Levels: Meet customer expectations consistently without inflating safety stock.

- Reduced Inventory Costs: Eliminate inefficiencies in ordering and storing excess inventory.

- Greater Agility: Respond to market changes and customer behaviour with minimal delays.

- Data-Driven Decision Making: Eliminate guesswork with actionable insights and predictive analytics.

- Scalability: Easily extend the model to multiple warehouses, regions, or product categories.

Challenges and Considerations

Despite the benefits, implementing an ML-based inventory optimisation model isn’t without its challenges:

- Data Quality: The accuracy of predictions is highly dependent on clean, well-structured data.

- Change Management: Integrating AI tools may face resistance from teams accustomed to legacy systems.

- Skill Requirements: Organisations need data scientists and supply chain experts to develop and maintain these models.

- Ethical Considerations: Over-reliance on algorithms may lead to unintended consequences if not regularly monitored.

Best Practices for Implementing an ML-Powered Inventory Optimisation Model

To reap the full benefits of machine learning in inventory management, businesses should follow these best practices:

- Start Small: Begin with a pilot project on a limited product line or region.

- Clean Your Data: Ensure your sales, supply, and warehouse data are accurate and integrated.

- Collaborate Cross-Functionally: Involve IT, supply chain, and finance teams from the start.

- Monitor Continuously: Regularly evaluate the performance of the inventory optimisation model and retrain algorithms as needed.

- Invest in Talent and Tools: Hire data scientists or partner with ML experts, and use cloud-based platforms for scalability.

The Future of Inventory Optimisation

As supply chains grow increasingly complex and customer expectations evolve, the traditional “one-size-fits-all” approach to inventory planning is no longer viable. Businesses that adopt a machine learning-based inventory optimization model will enjoy a significant competitive edge through smarter planning, reduced costs, and enhanced customer satisfaction.

In the future, we can expect to see autonomous inventory systems powered by AI that make decisions with little to no human intervention, capable of navigating even the most unpredictable supply chain disruptions.

FAQs – Inventory Optimisation Model

1. What is an inventory control model?

An inventory control model is a data-driven approach used to determine the optimal inventory levels that balance service levels with holding and ordering costs.

2. How does machine learning enhance inventory optimization?

Machine learning improves forecast accuracy, detects anomalies, updates rules dynamically, and segments inventory more intelligently, making the optimisation process more responsive and precise.

3. Is a machine learning-based model better than traditional methods?

Yes. While traditional models offer static solutions, machine learning enables dynamic and adaptive inventory management, which is crucial in today’s volatile markets.

4. Can small businesses benefit from using an inventory model?

Absolutely. With cloud-based solutions and pre-built ML tools, even small businesses can implement scalable inventory optimisation processes to improve efficiency.

5. How often should I update my inventory control model?

Ideally, the model should be reviewed and retrained regularly, especially when there are significant changes in demand patterns, supply chains, or product offerings.

Conclusion

An inventory optimization model is no longer just a theoretical tool—it is a practical necessity in the age of data-driven decision-making. With the infusion of machine learning, these models are becoming increasingly powerful, precise, and adaptable.

Whether you’re a supply chain manager in retail, manufacturing, or e-commerce, investing in a machine learning-powered inventory model is one of the smartest moves you can make for long-term sustainability and profitability.

The inventory control framework ensures that your business is always prepared, never overstocked, never understocked, and just right by bridging the gap between demand variability and inventory control. For detailed traceability analysis, get in touch with Qodenext today.