Are you looking for a technological powerhouse that will seamlessly orchestrate the complex operations of your industry? Well, industrial PCs are your saviors. These technological workhorses are not just your regular desktops or laptops. These are way more versatile, robust, efficient, and capable of handling extreme temperatures and conditions.

Well, what is an industrial PC? What are its features, & how does it differentiate from a regular desktop or PC? We’ll discuss all of your queries related to the industry in this blog. Without further delay, let’s get started!

What Is an Industrial PC?

An industrial PC is a computing machine designed specifically for an industry. These PCs are explicitly developed with technological advancements for machine automation purposes.

These devices can perform a wide range of functions, from controlling key operations and processes to monitoring parameters and signaling in case of anomalies. They come in various sizes but are mostly compact and can easily be mounted.

They come with an easy-to-use operating system like regular desktops, such as Windows and Linux. However, their processing power and storage capacity are tremendously impressive.

Being mostly used in industries and factories, they are known for their ability to work efficiently even under harsh conditions such as dusty areas, etc. Moreover, they work without any potential side effects like overheating, etc.

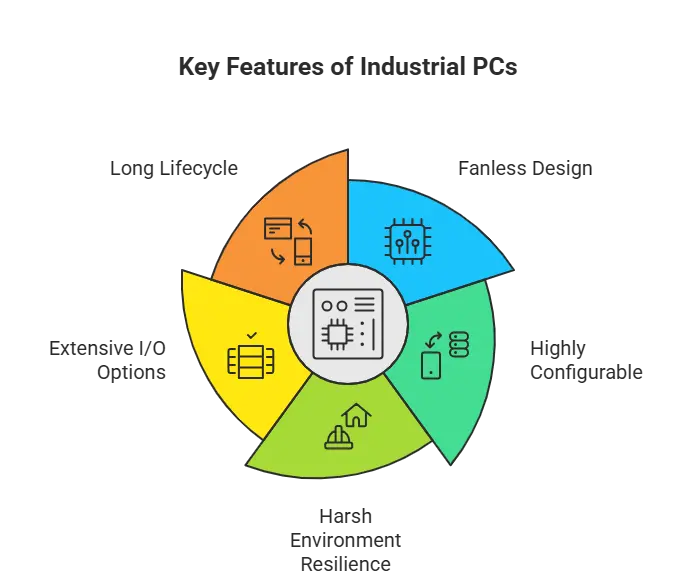

Features of an Industrial PC

Do you want to look at an industrial PC’s amazing features? Well, then, let’s go for it!

1. Fanless Design

You must have seen internal cooking fans on your commercial desktops and laptops. Surprisingly enough, industrial PCs are fanless. The reason behind their fanless design is that the fan also attracts dust particles along with the air from the environment, which may lead to hardware failure in the long run.

However, these devices have a proprietary heatsink design that they use to dissipate the heat to the surrounding environment.

2. Highly Configurable

The best part about industrial PCs is that you can use them for a wide range of applications, from remote data collection to remote machine control. You can easily customize their features to meet your specific demands. Moreover, you can easily integrate them with your other larger systems.

3. Ability to Withstand Harsh Environments

Industrial PCs are designed for industrial purposes. Thus, they can easily withstand high temperatures, dust, electromagnetic interference, etc. They come with special features (such as their fanless design) and robust manufacturing that are resistant to these common drivers of hardware failure in an industry environment.

You’ll be surprised to know that some varieties also come with a sealed enclosure, which keeps them safe even during liquid and contaminant spillage.

4. Extensive I/O Options

An industrial PC can seamlessly integrate and communicate with your other connected devices without adapters and dongles. They come with extension I/O options such as hot-swap drives, and COM, making them flexible and suitable for various applications.

5. Long Lifecycle

An industrial PC lasts for about five years without any major hardware changes. Being designed for an industry, they have features to work round the clock without breaks and issues of overheating.

Do you want to integrate an automation solution into your retail business? Worry not because we bring you QodeNEXT and its unique solutions, which are tailored to meet your unique needs, thus taking your business’s productivity and efficiency to the next level. Unlock the full potential of your business with QodeNEXT’s comprehensive suite of hardware and software solutions. Go check out QodeNEXT’s services now!

How Does an Industrial PC Differ from a Commercial PC?

You shouldn’t confuse an industrial PC with an upgraded version of a commercial PC. They have many differences, from their purpose to manufacturing and usage. Let’s explore some of the most common differences.

| Feature / Aspect | Industrial PC | Commercial PC |

| Purpose | Designed for industrial automation, control, and monitoring | Built for general personal or office use |

| Durability | Rugged build — resistant to heat, dust, vibration, and moisture | Not suitable for harsh or dusty environments |

| Operating Temperature | Typically -20°C to +70°C | 0°C to +35°C |

| Cooling System | Usually fanless (passive cooling) | Uses internal fans for cooling |

| IP Rating / Protection | High (often IP65 or above) — water & dust resistant | Low or none |

| Lifecycle | Long-term availability (up to 10–15 years) | Shorter lifecycle (3–5 years) |

| Components | Industrial-grade SSDs, capacitors, and connectors | Consumer-grade components |

| I/O & Expansion | Extensive — COM ports, USB, PCI slots, expansion bays | Limited ports and customization options |

| Performance Focus | Reliability, 24/7 operation, stability | Speed and cost efficiency |

| Cost | Higher initial cost, lower maintenance cost | Lower cost but higher maintenance risk |

1. Industrial Grade Components

Industrial PC systems are equipped with industrial-grade components, such as wide temperature range solid state disks, higher specification capacitors, and processors optimized for low power dissipation. They are designed to withstand harsh environments, operate at higher temperatures, and function in sealed or damp locations.

In contrast, commercial PCs use standard components that may not offer the same durability, temperature range, or power efficiency. As a result, they are generally less suitable for industrial settings.

2. Performance

Industrial PCs have high-end performance components, so you can easily run complex tasks with great reliability and precision. However, commercial PCs don’t have such components and are thus unable to handle such complex tasks. They are capable of handling general tasks only.

3. IP Protection

Industrial PCs typically have higher IP (Ingress Protection) ratings compared to commercial PCs. They are often water-resistant and dustproof, making them suitable for industrial applications like food manufacturing and chemical processing. Industrial PCs employ multiple points of failure elimination, such as specialized connectors like M12 connectors.

In contrast, commercial PCs usually have lower IP ratings and are not specifically built to withstand such extreme conditions.

4. Ruggedness and Reliability

As the name suggests, industrial PCs are designed to survive and work in harsh conditions within an industrial facility. This includes high temperature, humidity, dust, electromagnetic interference, etc.

On the contrary, commercial PCs can never survive in such a harsh environment and will show signs of hardware failure in no time.

5. Longevity

Industrial PCs have a longer lifespan of up to 15 years, making them suitable for long-term embedded computing solutions in industrial environments. In contrast, commercial PCs may require more frequent upgrades or retrofits due to the rapidly evolving technology in the consumer market.

6. Cost

Due to its features, build quality, and purpose. There is no doubt that industrial PCs require a significantly higher initial investment. However, their long life cycle ensures that there are little to no maintenance costs. In contrast, commercial PCs are budget-friendly but may require maintenance costs and are not suitable for rigorous industrial usage.

Wrapping Up

To sum up, industrial PCs offer robustness, reliability, and adaptability, which is why they are the backbone of modern automation and control systems. With real-time monitoring capabilities and seamless performance, they have revolutionized various industries. From manufacturing plants to transportation systems, industrial PCs are empowering organizations to achieve new heights of efficiency and productivity.

So, explore more on these devices before choosing the right one for your business. Also, to help you in your industrial automation journey, we present to you our solution, QodeNEXT. Get in touch with us now to help you make the best choice to manage your fleet and optimize your process!

FAQs: What Is an Industrial PC?

1. What is an industrial PC?

Simply put, an industrial PC is a computing machine that is designed specifically to be used in an industry.

2. How does an industrial PC work?

An industrial PC works pretty much similarly to a commercial PC using the principles of technology.

3. What are the various types of industrial PC?

There are three types of industrial PCs: Panel PCs (PPCs), Industrial Panel PCs (IPPCs), and Touch Panel PCs (TPCs).

4. What are the features of an industrial PC?

An industrial PC’s features include its robust manufacturing, high-performance processing and storage capabilities, extensive connectivity options, and ability to work in harsh conditions.

5. How does an industrial PC differ from a commercial PC?

Its purpose is the basic difference between an industrial PC and a commercial PC. While commercial PCs are built for personal and general tasks, industrial PCs are built specifically to be used in industrial operations.

6. What are the benefits of industrial PC?

Industrial PCs are meant to be used in the environment where reliability, durability and precision are important.

They are also able to work 24/7 in the most adverse conditions: heat, dust, vibration, or humidity without any system breakdowns as opposed to commercial desktops.

Key advantages include:

- Many years of operation (7-15 years in most cases)

- No fan design, low-maintenance construction.

- Extreme temperature and dust resistance.

- Large scale industrial level interconnection.

- Constant stability of automation and real-time control.

To sum up, an industrial PC guarantees regular availability as well as operational performance, so it is a brilliant investment in any factory or industrial organization.

7. On average, how long does an industrial PC last?

Industrial PCs are designed to last long. When well maintained, they can last reliably between 8 and 15 years as opposed to most consumer computers.

Their long life is attributed to:

- Industrial-grade (capacitors, SSDs, connectors) components.

- Wear reduction by passive cooling (no fan).

- Ongoing support by the manufacturer and uninterrupted supply of parts.

The high lifecycle of industrial PCs makes them affordable in automation projects where the hardware needed to be stable over many years.

8. Are industrial PCs more power consumption than regular PCs?

Not necessarily. Most of them are designed to be efficient when loaded with parts that are designed to work in industrial conditions. Nevertheless, the design and application of power depends on the model.