Introduction:

In the intricate web of supply chain management, warehousing plays a pivotal role in ensuring the smooth flow of goods from manufacturers to consumers. The term warehousing in supply chain management encompasses a range of facilities and strategies aimed at efficient storage, handling, and distribution of products. These warehouses serve as critical nodes in the supply chain, strategically positioned to optimize inventory management and streamline the overall logistics process. As businesses strive for enhanced operational efficiency, understanding the diverse types of warehouses becomes crucial. From private warehouses to automated warehouse racking systems, each type contributes uniquely to the complex tapestry of supply chain management.

Private Warehouse Example

Unlocking the potential of supply chain optimization, private warehouses stand as veritable bastions of logistical efficiency. Let’s embark on a comprehensive journey into the realm of private warehousing, unraveling the intricacies that make these facilities indispensable for modern businesses.

1. Strategic Storage Solutions:

- In the orchestration of supply chain symphonies, private warehouses emerge as dedicated repositories tailored to the unique needs of individual enterprises. The heartbeat of strategic storage precision, these facilities allow companies to choreograph their inventory management with finesse.

- Private warehouse resonates with exclusivity, symbolizing a bespoke storage space meticulously crafted for the idiosyncrasies of a single organization.

2. Enhanced Security Measures:

- Imbued with an air of exclusiveness, the keyword private warehouse amplifies the resonance of security eminence. These warehouses become fortresses of protection, where advanced security measures, ranging from cutting-edge surveillance systems to access controls, ensure the impervious safeguarding of valuable goods.

- The repetition of the term emphasizes the encapsulated nature of security, reinforcing the notion of a distinctly private and secure space.

3. Customizable Layouts:

- Private warehouses present a canvas of architectural flexibility, enabling businesses to compose their storage symphony with a bespoke touch. The customizable layouts reflect an orchestration of space that harmonizes with the unique cadence of the stored products.

- The recurrent presence of private warehouse underscores the tailor-made architectural symphony that businesses can conduct within these storage havens.

4. Streamlined Operations:

- Beyond storage, private warehouses choreograph the dance of logistics and distribution with unparalleled elegance. Centralizing inventory management, these facilities unravel a performance where lead times shrink, transportation costs waltz downward, and order fulfillment pirouettes at an accelerated pace.

- The reiterated use of the term private warehouse accentuates the exclusivity and elegance embedded in the operational dance of these dedicated storage spaces.

5. Cost-Efficient Solutions:

- Establishing a private warehouse demands an initial investment, yet its allure lies in the symphony of long-term benefits. Companies find solace in the frugality of optimized storage, reduced carrying costs, and the opulent return on investment derived from a more cost-efficient supply chain.

- The persistent recurrence of private warehouse underscores the economic symphony, highlighting how businesses can orchestrate fiscal harmony within these exclusive storage domains.

6. Adaptability to Business Growth:

- Private warehouses crescendo with adaptability, harmonizing seamlessly with the ever-evolving cadence of business growth. Whether businesses experience a sonorous rise or a subtle diminuendo in demand, these warehouses elegantly adjust their spatial notes, ensuring an agile and responsive supply chain.

- The reiterated reference to a private warehouse amplifies the adaptability, portraying these facilities as dynamic orchestrators responding to the crescendos and decrescendos of business dynamics.

In summation, the concept of a private warehouse transcends conventional storage, offering businesses a personalized, secure, and efficient symphony for their inventory management. The repetitive interlude of the keyword private warehouse serves as a thematic refrain, underscoring the exclusivity and customization intrinsic to these modern storage maestros.

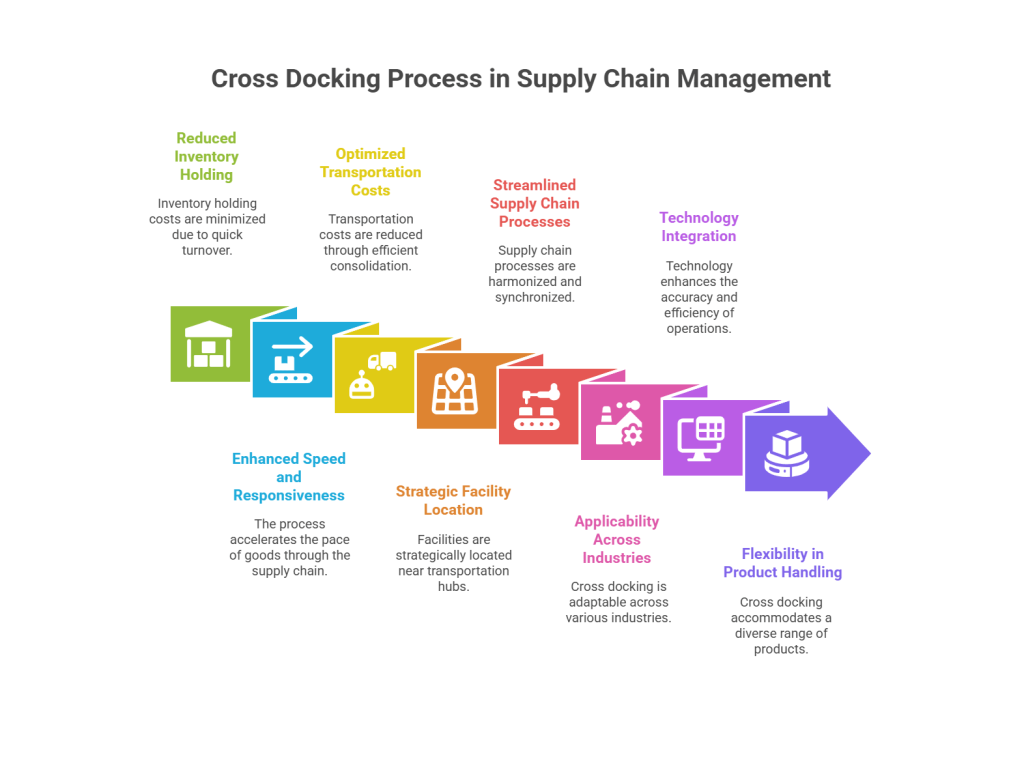

Cross Docking In SCM

In the intricate realm of Supply Chain Management (SCM), the strategic dance of cross docking has emerged as a revolutionary choreography, challenging traditional logistics norms and reshaping the trajectory of goods through the supply chain. This groundbreaking approach involves the seamless transfer of products from inbound to outbound transportation hubs, minimizing storage times and heralding a new era of efficiency. Explore the distinctive facets of cross docking through a fresh perspective:

1. Reduced Inventory Holding Costs:

- Cross docking disrupts the traditional inventory landscape, ushering in a paradigm where extensive warehousing takes a backseat.

- The swift transition of goods from receipt to dispatch not only slashes holding costs but also propels businesses towards a more nimble, responsive inventory management approach.

2. Enhanced Speed and Responsiveness:

- – At its core, cross docking is a catalyst for accelerating the pace at which goods navigate the supply chain, challenging the inertia of conventional processes.

- – This newfound velocity becomes a competitive advantage, empowering businesses to navigate swiftly through market shifts and meet the dynamic expectations of consumers.

3. Optimized Transportation Costs:

- Beyond its immediate impact, cross docking orchestrates a symphony of efficiencies in transportation logistics, reshaping the economic landscape of supply chain operations.

- Through adept consolidation and deconsolidation, this strategy optimizes truckload capacities, eliminating inefficiencies associated with empty backhauls and fostering a sustainable, cost-effective transport ecosystem.

4. Strategic Facility Location:

- The geographical orchestration of cross docking facilities strategically situates them in proximity to transportation hubs, manufacturing nodes, or distribution centers.

- This strategic placement becomes a pivotal move in reducing transit times, amplifying the speed at which products traverse the supply chain maze.

5. Streamlined Supply Chain Processes:

- Cross docking’s distinctive feature lies in its ability to harmonize the various elements within supply chain processes, orchestrating a symphony of seamless, synchronized operations.

- Bottlenecks dissipate, unnecessary delays dissolve, and businesses find themselves orchestrating a finely tuned supply chain symphony, resonating with efficiency.

6. Applicability Across Industries:

- Transcending industry boundaries, cross docking proves its mettle across the retail, manufacturing, and distribution spectrums.

- Its adaptability renders it a universal tool for businesses dealing with diverse product portfolios, making it not just a strategy but a strategic imperative in the modern SCM arsenal.

7. Technology Integration:

- The success narrative of cross docking intertwines with the strategic infusion of cutting-edge technologies.

- Real-time tracking, RFID systems, and the automation of material handling systems choreograph the accuracy and efficiency of cross docking operations, transforming them into a technological ballet.

8. Flexibility in Product Handling:

- From the delicate handling of perishable goods to the efficient processing of high-demand items, cross docking accommodates a diverse range of products.

- Its versatility positions it as a nimble dancer on the SCM stage, adapting effortlessly to the ever-changing rhythms of market demands.

Cross docking is not merely a logistical tool but a transformative force reshaping the very essence of Supply Chain Management. As businesses navigate the evolving landscape, the adoption of cross docking becomes not just a strategic choice but an organic response to the demands of a dynamic market. In this era of constant flux, cross docking stands as a beacon, ushering in a new paradigm where speed, efficiency, and adaptability converge to redefine the contours of supply chain success.

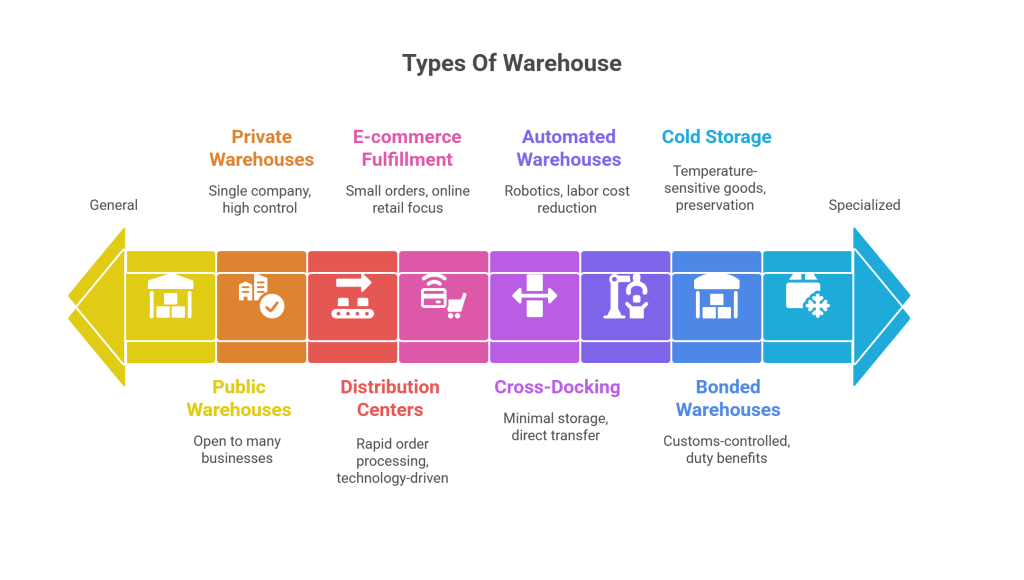

Types Of Warehouse

Warehouses stand as the silent guardians of the supply chain, orchestrating the intricate dance of storage and distribution. A nuanced understanding of the various warehouse types is imperative for businesses seeking to fine-tune their logistics operations. Let’s embark on a journey to unravel the intricacies of these storage havens.

1. Public Warehouses:

- Embraced by third-party logistics virtuosos.

- Extend an open invitation to myriad businesses seeking storage and distribution prowess.

- An agile choice for enterprises grappling with the ebb and flow of inventory demands.

2. Private Warehouses:

- Crafted exclusively for the solitary embrace of a single company.

- Bestow unparalleled control over the symphony of inventory management.

- A fortress for businesses boasting consistent and voluminous storage needs.

3. Distribution Centers:

- The maestros of order fulfillment, strategically positioned to harmonize with minimized transportation cadences.

- Infused with cutting-edge technology orchestrating a symphony of rapid order processing.

- The epicenter of efficiency for businesses navigating the ever-demanding realm of customer expectations.

4. Cold Storage Warehouses:

- Purpose-built sanctuaries for the guardianship of perishable treasures.

- Reverberate with the hum of refrigeration and temperature control, safeguarding the essence of food, pharmaceuticals, and other delicate commodities.

- A vital nexus for preserving the integrity of temperature-sensitive cargos.

5. Automated Warehouses:

- The avant-garde utopia of robotics and automated ballets, gracefully handling the nuances of material logistics.

- Orchestrating an efficiency sonata, alleviating the burden of labor costs.

- The sanctum for businesses seeking a seamless marriage of technology and operational finesse.

6. Bonded Warehouses:

- Governed by the customs alchemy, these vaults harbor imported treasures awaiting their destiny.

- Pave the way for deferred or diminished customs duties, rendering a financial respite.

- A haven where goods contemplate the possibility of re-export without the shackles of duty.

7. E-commerce Fulfillment Centers:

- Specially curated amphitheaters dedicated to the intricacies of online retail’s symphony.

- Embrace the technological crescendo to gracefully manage the ballet of small orders.

- The pulsating heart of swift order processing, where customer satisfaction takes center stage.

8. Cross-Docking Warehouses:

- The magicians of storage alchemy, minimizing the temporal embrace with a direct transference from inbound to outbound realms.

- An operational minuet, orchestrating a streamlined supply chain for the swift-footed products.

- Where the need for extended storage becomes an anachronism in the face of an agile, cross-docking waltz.

In the dynamic theatre of logistics, the choice of warehouse type emerges as a strategic overture, setting the tempo for operational symphonies. Whether entrusting the soul of goods to a public refuge or cocooning them in the exclusivity of a private sanctum, the tapestry of warehouse diversity unfurls, adapting to the ever-evolving dance of the global market.

Types Of Warehouse – In the grand tapestry of logistical intricacies, warehouses stand as the unsung heroes, offering a myriad of solutions to meet the diverse needs of industries. The selection of the right warehouse type is a strategic decision, a cornerstone influencing a company’s operational prowess and customer satisfaction.

Automated Warehouse Racking System

In the dynamic realm of logistics and supply chain optimization, the quest for efficiency never rests. In response to this ever-present demand, a technological marvel has emerged to redefine warehouse management – the Automated Warehouse Racking System.

1. Revolutionizing Warehousing Dynamics

At the core of this transformative technology lies a symphony of cutting-edge sensors, robotics, and intelligent algorithms, choreographed to elevate the storage and retrieval processes to unparalleled heights of precision and speed.

2. The Intricacies of Automation

The Automated Warehouse Racking System orchestrates a seamless dance between machinery and algorithms, undertaking tasks ranging from the loading and unloading of pallets to the meticulous organization of inventory. Unlike traditional manual systems, this automated marvel operates with a precision that reshapes our understanding of warehouse management.

3. A Symphony of Efficiency

A pivotal strength of the Automated Warehouse Racking System is its capacity to minimize human involvement in routine tasks, leading to a cascade of benefits. Error reduction, heightened inventory accuracy, and swift order fulfillment become the norm, marking a paradigm shift in warehouse efficiency.

4. Optimized Storage and Spatial Intelligence

This system’s intelligent algorithms delve into the intricacies of inventory data, strategically placing goods within the warehouse. The result? A maximized storage capacity that efficiently utilizes space, allowing businesses to store more products without expanding their physical footprint.

5. Anticipating the Future of Logistics

As we gaze into the future of logistics, the Automated Warehouse Racking System emerges as a beacon of innovation. Its adaptability to dynamic demands, coupled with its potential integration with emerging technologies like artificial intelligence and the Internet of Things, positions it as a versatile solution for businesses of all sizes.

8. Sustainability and Financial Efficiency

Beyond its operational advantages, the Automated Warehouse Racking System champions environmental sustainability. The optimized use of space reduces the need for expansive warehouses, curbing the overall carbon footprint of logistics operations. Moreover, its energy-efficient design translates into substantial long-term cost savings.

The Automated Warehouse Racking System is not merely a technology; it’s a harbinger of change in the logistics landscape. By seamlessly weaving automation into warehouse operations, businesses can attain unprecedented levels of efficiency, accuracy, and sustainability. In a world where the pursuit of faster and more reliable logistics solutions is unceasing, the Automated Warehouse Racking System stands tall, pushing the boundaries of what is possible and ushering in an era where efficiency knows no constraints.

Conclusion:

In the dynamic landscape of supply chain management, choosing the right warehousing strategy is paramount. From private warehouses tailored to specific company needs to the efficiency boost provided by automated warehouse racking systems, each aspect contributes to the overall success of the supply chain. As businesses navigate this intricate network, embracing advanced solutions becomes imperative. Qodenext, a pioneer in innovative logistics solutions, understands the nuances of warehousing in supply chain management, providing businesses with the tools to thrive in today’s competitive markets.

FAQs:

1. What are the different types of warehouses in supply chain management?

Warehousing in supply chain management involves various types such as private warehouses, public warehouses, and distribution centers. Each serves distinct purposes, catering to the specific needs of businesses in the supply chain.

2. Can you provide an example of a private warehouse in the supply chain?

Certainly. A private warehouse is a facility owned and operated by a single company exclusively for its products. An example is a manufacturer maintaining its private warehouse to store and manage its inventory.

3. What role does cross-docking play in supply chain management?

Cross-docking is a logistics strategy where goods from inbound trucks are directly transferred to outbound trucks with minimal or no storage time. This technique reduces inventory holding costs and expedites the delivery process.

4. How does an automated warehouse racking system contribute to supply chain efficiency?

An automated warehouse racking system utilizes technology to manage and organize inventory. It enhances efficiency by automating tasks like picking, packing, and retrieval, minimizing human error and speeding up operations.

5. Are there specific industries that benefit more from private warehouses?

Yes, industries with seasonal demand fluctuations, perishable goods, or those requiring specialized storage conditions often find private warehouses advantageous for tailored storage solutions.

6. What distinguishes distribution centers from other types of warehouses?

Distribution centers focus on rapid order fulfillment and efficient product distribution, acting as intermediaries between manufacturers and retailers to streamline the supply chain.

7. How can businesses optimize their warehousing strategies for cost-effectiveness?

Businesses can optimize warehousing costs by adopting technologies like automated systems, implementing efficient inventory management, and strategically locating warehouses to minimize transportation expenses.