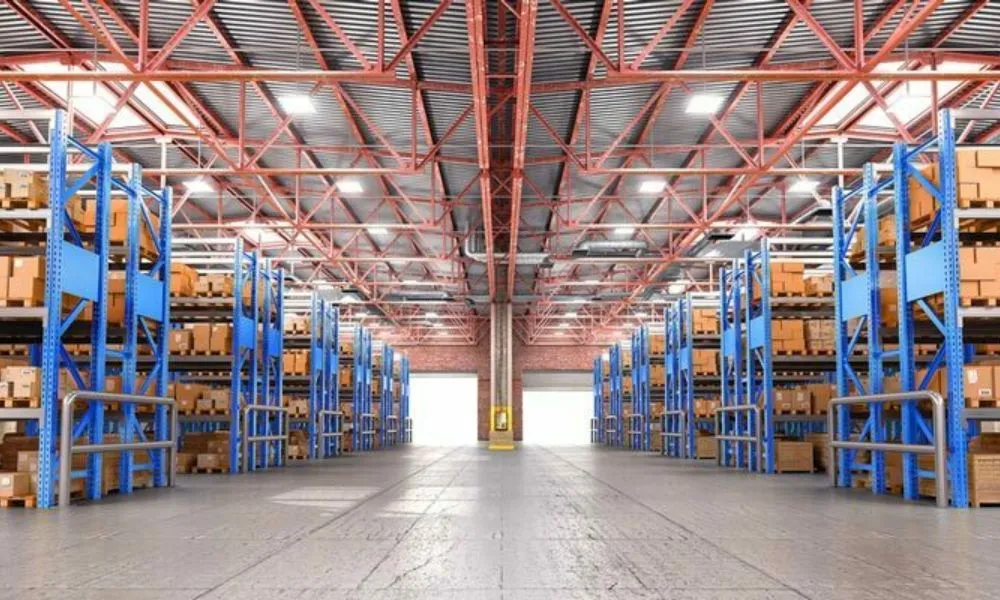

Think of a warehouse where chaos reigns supreme – tools scattered, inventory misplaced, and productivity compromised. Now, picture a warehouse where everything is meticulously organized, processes flow seamlessly, and productivity soars. The difference between the two lies in the implementation of the 5S warehouse methodology, which acts as a guiding light in the world of warehousing and logistics. By adhering to the 5S warehouse approach, warehouses can seamlessly transform from scenes of cluttered chaos to hubs of streamlined efficiency. 5S in warehouse management is the key to achieving this transformation.

According to a survey conducted in India, revealing that nearly 65% of warehouses grapple with disorganized layouts and inefficient processes, the significance of the 5S principles becomes all the more apparent. These principles step in as a structured framework, offering warehouses the tools they need to overcome challenges and optimise their operations effectively. Eager to know more about it? Why wait? Let’s dig in!

The 5S Methodology Explained

In the world of warehouse management, the 5S methodology is a beacon of efficiency and organisation. This systematised approach, born in Japan and firmly grounded in the principles of Lean manufacturing, has revolutionised how workplaces are structured and managed. The 5S warehouse framework, with its five core principles, each beginning with the letter ‘S’, is like a compass guiding warehouses towards creating an environment that is not only well-organised but also highly efficient and safe.

- Sort (Seiri)

Imagine a warehouse where every item serves a purpose, where every corner is optimised for function, and where unnecessary clutter is absent. This is the goal of the first ‘S’ – Sort. It involves a meticulous process of evaluating every item, piece of equipment, and material within the warehouse. The aim is to identify and eliminate items that are redundant, obsolete, or seldom used. By streamlining the inventory, warehouses free up valuable space and reduce the risk of accidents caused by navigating through unnecessary obstacles. The mantra is to keep only what is essential, creating a warehouse where every item has its designated spot, ensuring that employees can locate and access what they need with ease.

- Set in Order (Seiton)

The second principle, “Set in Order,” might be likened to giving everything a proper home. Imagine a warehouse where tools, products, and equipment are stored in a structured and logical manner. This principle is all about optimising workflow by ensuring that items are easily accessible when required. In a bustling warehouse environment, quick access to necessary items is crucial for maintaining efficiency. To achieve this, the principle of Set in Order advocates for strategic organisation through proper labelling, well-defined storage systems, and effective visual cues. This strategic arrangement minimises the time taken to locate and retrieve items, contributing to the overall efficiency of operations.

- Shine (Seiso)

The third principle, Shine, goes beyond surface-level aesthetics. It’s about creating an environment that radiates cleanliness and orderliness. Regular and thorough cleaning not only enhances the visual appeal of the warehouse but also plays a pivotal role in ensuring the safety of employees and the preservation of inventory. A clean workspace minimises the risk of accidents, reduces the accumulation of dirt and debris, and prolongs the lifespan of equipment. Imagine a warehouse where floors gleam, shelves are dust-free, and everything is in its rightful place. Incorporating the Shine principle transforms the warehouse into a healthy and efficient space, conducive to productive work.

- Standardise (Seiketsu)

The fourth ‘S’, Standardise, takes the momentum gained from the previous principles and transforms it into lasting efficiency. Once Sort, Set in Order, and Shine are in place, it’s essential to standardise procedures and practices to maintain this organised state. This involves creating clear guidelines for tasks such as cleaning routines, item placement protocols, and inventory management practices.

Consistency in processes ensures that the benefits of the 5S warehouse methodology are sustained over time, even as new employees join the workforce. Imagine a warehouse where everyone follows standardised practices, leading to a seamless and efficient workflow, regardless of who is involved.

- Sustain (Shitsuke)

The final ‘S’, Sustain, underscores the continuous nature of the 5S warehouse methodology. It’s about instilling a culture of discipline and self-accountability within the workforce. Sustaining the organised and efficient state of the warehouse requires active participation from all levels of the organisation. Regular audits, training sessions, and ongoing employee involvement are crucial to ensure that the principles are adhered to and the workspace remains optimised.

Imagine a warehouse where the 5S approach is ingrained in the company culture, and every individual takes ownership of keeping the workspace organised and efficient. This level of commitment and collaboration is what sustains the 5S methodology’s effectiveness in the long run.

Implementing 5S in Warehouse Operations

Now, let’s delve into the practical aspects of implementing the 5S principles in warehouse operations, detailing each step to ensure a comprehensive understanding of the process:

- Assessment

Before embarking on the 5S journey, it’s crucial to start with a comprehensive assessment of your warehouse. This involves conducting a thorough audit of the current state of affairs. Walk through the entire space, observing workflow patterns, storage arrangements, and potential bottlenecks. Identify areas that require improvement, whether it’s cluttered storage areas, inefficient item placement, or lack of safety measures. This assessment phase acts as the foundation upon which the rest of the 5S process will be built.

- Employee Involvement

Your warehouse staff is the heartbeat of your operations. Their insights and experiences are invaluable in shaping the effectiveness of the 5S implementation. Involve them right from the beginning. Conduct brainstorming sessions or focus groups to gather their perspectives on pain points, challenges, and potential solutions. This not only empowers your employees but also provides practical insights into the workflow, enabling you to tailor the 5S principles to the unique needs of your warehouse.

- Training

One of the cornerstones of successful 5S implementation is a well-informed and educated workforce. Ensure that all employees, from supervisors to frontline workers, are well-versed in the 5S principles and understand their significance. This understanding is essential for fostering a sense of ownership and commitment towards the implementation process. Arrange workshops, training sessions, and presentations to explain the benefits of 5S, how it aligns with the warehouse’s goals, and the role each employee plays in its success.

- Sorting and Organizing

The Sorting phase is where the transformation begins. Start by decluttering the workspace. This involves systematically going through every area and item within the warehouse. Identify items that are redundant, obsolete, or rarely used. Dispose of them responsibly or consider relocating them to a designated storage space. Once the unnecessary items are removed, shift your focus to organising what remains. Arrange items in a way that aligns with the workflow. Group similar items together, keeping frequently used items within easy reach. This is also an opportunity to design dedicated storage spaces, ensuring that items have designated spots for optimal organisation.

- Visual Management

Incorporating visual cues is like creating a visual map that guides employees through the 5S warehouse principles. Labels, colour coding, and floor markings play a crucial role in this phase. For instance, label shelves and bins with clear descriptions of what belongs there. Use color-coded markers to differentiate between zones or types of items. Implement floor markings to indicate pathways and safe zones. Visual cues streamline processes, making it easier for employees to identify where items belong and encouraging them to maintain the organised state. It’s a subtle yet highly effective way to ingrain the principles into everyday practices.

- Regular Audits

The sustainability of the 5S warehouse methodology relies on consistent reinforcement. Set up a schedule for regular audits to evaluate how well the principles are being followed. Assign a team or designate responsible individuals to conduct these audits. During these assessments, evaluate the workspace’s adherence to the principles. Identify areas that may have deviated from the organised state and address these deviations promptly. Regular audits not only help maintain the 5S standards but also provide an opportunity to fine-tune the implementation strategy based on real-time feedback.

Benefits of Implementing 5S in Warehouse Operations

Embracing the 5S warehouse a methodology offers a plethora of substantial benefits that ripple through every aspect of warehouse operations:

- Improved Efficiency: The meticulously organised workspace leads to streamlined processes, significantly reducing the time employees spend searching for items or navigating through cluttered spaces. This enhanced efficiency directly translates to quicker order fulfilment and increased customer satisfaction.

- Enhanced Safety: By eliminating potential hazards and maintaining a consistently clean environment, the risk of accidents and injuries is drastically reduced. A safer warehouse environment not only protects employees but also minimises the chances of damage to valuable inventory.

- Optimised Space: Efficient utilisation of space is a hallmark of the 5S methodology. This optimization can lead to increased storage capacity within the existing infrastructure, potentially eliminating the need for costly expansions or additional storage facilities.

- Elevated Employee Morale: A clean, organised, and safe workspace has a direct impact on employee morale and motivation. When employees work in an environment that supports their well-being, they are more likely to be engaged and productive, leading to improved overall work quality.

- Reduced Costs: Efficient processes naturally lead to reduced wastage of time and resources. The streamlined workflow minimises unnecessary steps and ensures that tasks are completed with precision, ultimately contributing to significant cost savings over time.

FAQS

What is 5S in warehouse management?

5S in warehouse management is a lean methodology aimed at improving efficiency and organization. It stands for Sort, Set in Order, Shine, Standardize, and Sustain.

Can you suggest some 5S ideas for a warehouse?

Sure! Here are some 5S ideas for a warehouse:

- Sort: Remove unnecessary items and clutter.

- Set in Order: Arrange tools and materials for easy access.

- Shine: Regularly clean the workspace and equipment.

- Standardize: Develop standard operating procedures.

What are some key aspects of warehouse safety?

Warehouse safety involves implementing regulatory guidelines and best practices to ensure a safe work environment.

In Conclusion

In conclusion, the 5S warehouse methodology offers a proven roadmap for transforming warehouses into efficient, organised, and productive spaces. By understanding and implementing the five principles – Sort, Set in order, Shine, Standardise, and Sustain – businesses can unlock the full potential of their warehouses. As the logistics industry in India and globally continues to evolve, embracing methodologies like 5S becomes essential for staying competitive.

If you’re ready to take the next step in warehouse excellence, consider exploring Qodenext. Qodenext is a leading provider of warehouse management solutions that seamlessly integrate with the 5S methodology. By combining cutting-edge technology with established principles, Qodnext empowers warehouses to achieve new levels of efficiency, accuracy, and operational excellence.