Imagine working in a streamlined, orderly warehouse where every available inch is used, goods easily move through the system, and production rises. That’s the power of a great warehouse design!

One thing is certain, regardless of your experience level in the field: your warehouse design has the power to make or ruin your business. But one with a bad design? That guarantees chaos and inefficiency. However, there is a fix! Through the application of strategic warehouse design ideas, your area can be transformed into an extremely efficient powerhouse.

Prepared to maximize your warehouse’s potential? Explore our in-depth blog on warehouse layout efficiency to learn the strategies and tactics that will help you advance your business. So, let’s keep going!

Understanding Warehouse Design

First, let’s clarify what is meant by “warehouse design”- this involves setting up your warehouse’s physical architecture to optimize productivity and efficiency. This covers everything, from the arrangement of racks and shelves to the movement of products and the utilization of available space. The final objective? to design a warehouse that maximizes efficiency, reduces waste, and is simple to navigate.

Principles of Warehousing

It’s crucial to comprehend certain fundamentals of warehousing concepts before getting into the specifics of its design. Here are some ideas that you should remember for building up a productive warehouse:

- Accessibility: Make certain that every item is simple to reach and obtain which means setting up your warehouse so that every item can be accessed quickly and easily.

- Flow: Consider how products move through your warehouse; the movement of your commodities should be orderly and seamless from receipt through storage and shipping.

- Space Utilization: Utilize as much of the space you have which means making effective use of your available area in addition to packing as much as you can into your warehouse.

- Safety: This should always be your priority which entails planning your warehouse to reduce risks and guarantee a secure working environment for your employees.

Types of Warehouse Layout

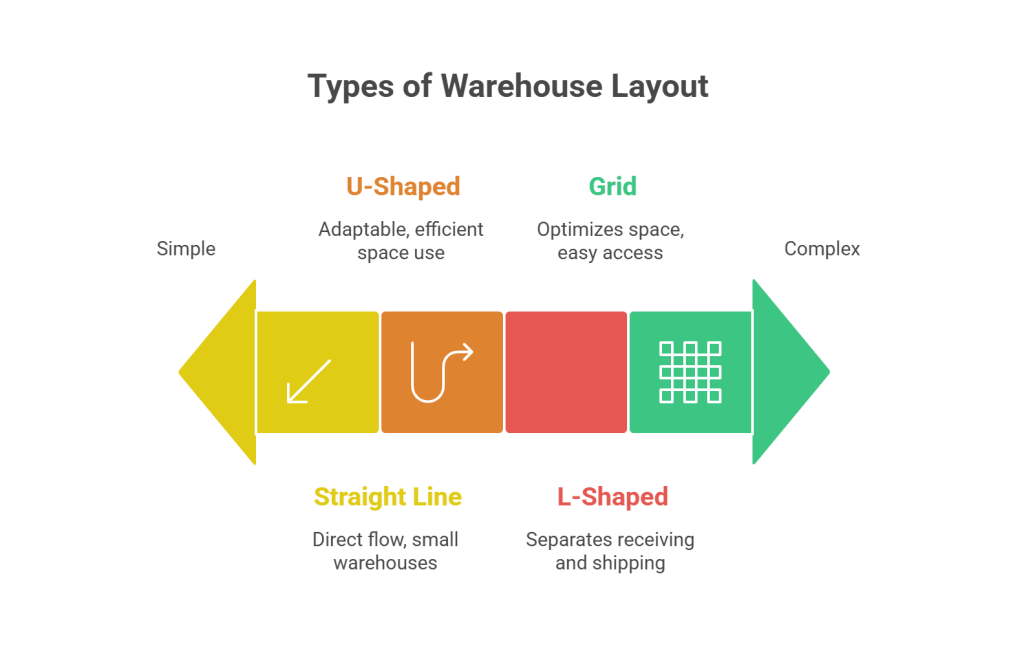

After understanding some basic concepts and principles, let’s discuss the many kinds of warehouse layouts. There are various popular designs, and each has benefits and drawbacks of its own; here’s a summary:

1. The U-Shaped Design

This is one of the most popular and adaptable warehouse layouts where your goods flow in a U-shape where reception and shipping sections are situated next to one another. This design facilitates simple access to the goods and effective use of available space. Additionally, it cuts down on employee travel time, which can increase output.

2. L-Shaped Layout

This is quite similar to the U-shaped design but with a slight difference, the receiving and shipping sections of the warehouse are arranged in an L-shape, with their locations at opposing ends. This arrangement is ideal for warehouses that handle large volumes of cargo as it allows for a clear separation between receiving and shipping activities.

3. Straight Line Layout

In this simple and efficient layout, goods moving from reception to shipment in a straight line is perfect, especially when you have smaller warehouses or those with a clear flow of goods. It might not be appropriate for warehouses that handle complicated procedures or a large quantity of items.

4. Grid Layout

Another popular style, particularly for larger warehouses, is the grid arrangement where you can arrange your products in this layout so that aisles are perpendicular to one another and form a grid-like pattern. This helps you make optimum use of available space and facilitates simple access to commodities. It is also easily adjustable to suit modifications in operations or inventories.

Objectives of Warehousing

Now, let’s discuss the goals that can help you determine the layout and design of your warehouse. Keep exploring!

1. Increasing Space Utilization

Making the best use of your spaces is one of warehousing’s main goals which entails planning your warehouse so that you can keep as much stock without sacrificing your security or ease of use.

2. Boost Productivity

Increasing the effectiveness of your operations is another important goal that involves cutting waste, streamlining the flow of commodities, and limiting the amount of time that workers must travel. A well-planned warehouse can assist you in reaching these objectives and increasing productivity.

3. Enhance Safety

You should always prioritize safety in your warehouse which means reducing the risk of your warehouse and guaranteeing a secure working environment for your employees. This can be everything from appropriate ventilation and lighting to safe storage procedures and clear signage.

4. Increase Output

Last but not least, a finely designed warehouse ought to boost your productivity including designing a layout that reduces downtime, facilitates simple access to items, and optimizes operations. You may build a profitable and efficient warehouse by accomplishing these goals.

Tips For Optimizing Your Warehouse Layout

Now that the fundamentals have been discussed, let’s dive into the specifics of maximizing your warehouse structure. Here are some pointers and advice to get you going:

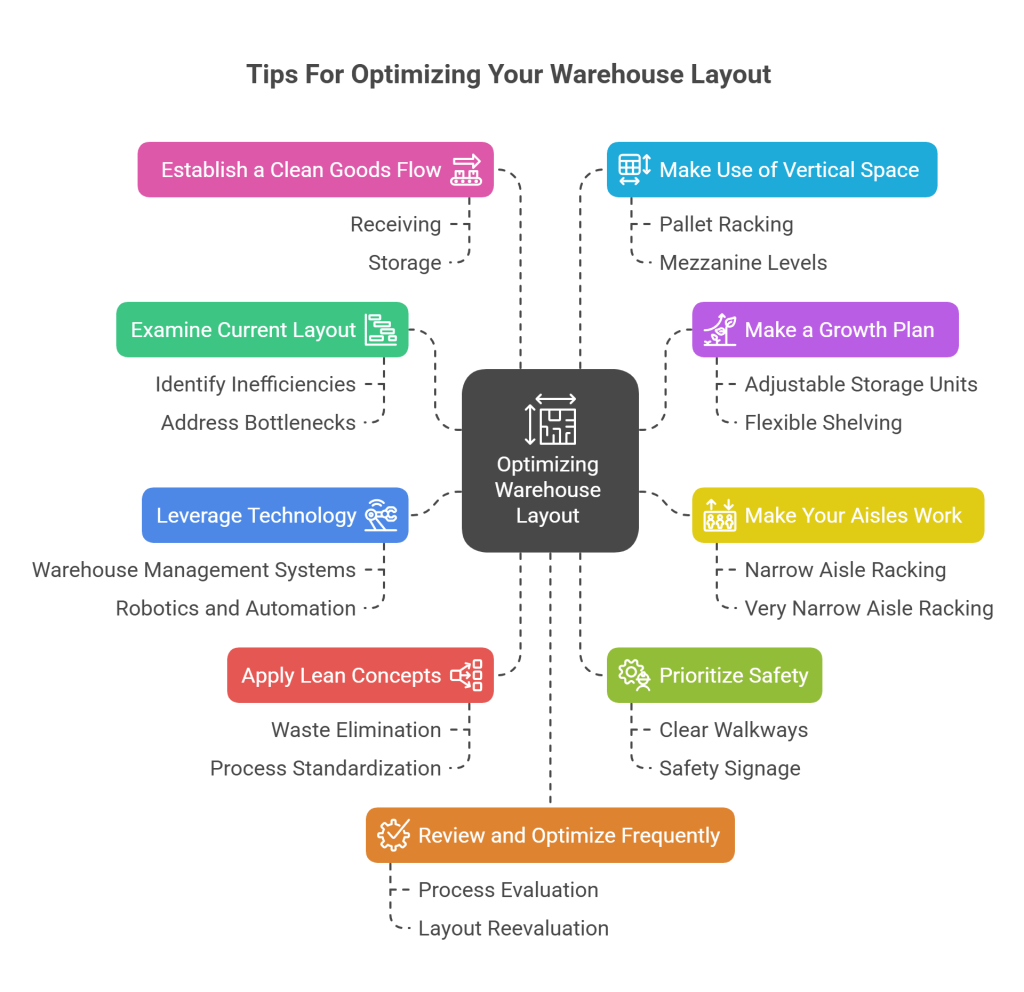

1. Examine Your Current Layout

Before making any changes, carefully assess your current warehouse layout to identify any inefficiencies or bottlenecks and try to address them. This might involve shifting your flow of goods, moving your shelves, or even reevaluating your entire design.

2. Make a Growth Plan

While planning about the design of your warehouse it is vital to think about your future which means making growth plans and ensuring that your layout can adapt to adjustments in inventory or operational changes. Also, try and use easily adjustable modular storage units or flexible shelving to meet your changing demands.

3. Make Your Aisles Work

You may learn that the width and layout of your aisles heavily exemplifies your efficiency; it should allow easy access to the merchandize without being too wide. It becomes important to begin implementing the applications of narrow aisle (NA) or very narrow aisle (VNA) racking systems to make the best of the available area.

4. Leverage Technology

WMS or warehouse management systems are useful in monitoring the stocks and flow of products within the warehouse facilities. Technologies also allow increasing the speed and productivity of work, as well as optimizing existing processes, for example, using robotics and automation, and, with their support, you can progress in developing the layout of your warehouse.

5. Apply the Lean Concepts

Implementing some of the lean principles like waste elimination, process standardization, and unfaltering process enhancement, you can develop the efficient and productive warehouse you need. You should consider utilizing such methods as the 5S (Sort, Set in order, Shine, Standardize, Sustain) method to improve the rate of productivity on the territory of your warehouse.

6. Prioritize Safety

As we’ve already said, the highest focus should always be on your warehouse safety which means planning your warehouse to reduce risks and guarantee a secure working environment. To improve your safety, think about implementing clear walkways, adequate lighting, safety signage, and introducing risk-handling programs. You should also ensure that everyone on your team is aware of their potential risks and recommended practices.

7. Establish a Clean Goods Flow

The efficient flow of items through your warehouse is essential, so, for that, you need to look after the layout starting from the movement of your goods to receiving, storage, and shipment. This way you can cut down your workers’ travel time and there is less chance of mistakes.

8. Make Use of Vertical Space

Pallet racking and mezzanine levels are examples of vertical storage that let you store more goods and maximize the space you have available. Just keep in mind to prioritize safety and ensure that these solutions are reliable and secure.

9. Review and optimize frequently

The task of warehouse design is not something that should be completed once and forgotten. So, you should keep checking your processes and layout frequently to find those places that need improvement. This includes shifting the flow of goods, moving the shelves, or even reevaluating the entire design. You can ensure that your warehouse stays productive and effective by constantly optimizing it.

Conclusion

Although designing your warehouse may seem challenging, you can build it productively and efficiently with a little planning and preparation. Always put safety first, remember the basics of warehousing, and also take into account its various layouts. You may quickly grow your company and optimize the potential of your warehouse by putting our advice and techniques into practice. So roll up your sleeves and get ready to turn your warehouse into a well-oiled machine!

FAQs: Top Warehouse Design Principles to Maximize Efficiency and Productivity

1. How often should I review and update my warehouse layout?

It’s recommended to review your warehouse layout at least once a year. However, if your business is experiencing growth, shifting product lines, or operational changes, more frequent reviews (quarterly or bi-annually) can help maintain peak efficiency and adaptability.

2. Can technology help in designing my warehouse layout?

Yes, leveraging warehouse management systems (WMS) and layout design software can significantly enhance your planning process. These tools provide real-time inventory data, simulate layouts, identify inefficiencies, and allow you to plan space utilization more accurately and proactively.

3. What’s the best way to train my team on a new warehouse layout?

Hands-on training, visual walkthroughs, and clear signage are the most effective. Use floor maps, hold team meetings to explain workflow changes, and encourage questions and feedback. Continuous training ensures smooth adaptation and better operational performance.

4. What are the most common warehouse layout types?

The most popular warehouse layouts are U-shaped, L-shaped, straight-line, and grid-style designs. Each has unique benefits depending on the warehouse size, flow of goods, and operational complexity. Choosing the right layout should align with your current and future business goals.

5. How can vertical space be used effectively in a warehouse?

Vertical space can be optimized by installing pallet racking systems, mezzanines, or overhead storage platforms. This allows you to expand your storage capacity without physically expanding the warehouse footprint. Always ensure structural safety and accessibility when using vertical storage.

6. How does warehouse layout impact productivity?

A well-optimized layout reduces travel time, enhances pick-pack efficiency, supports seamless inventory flow, and minimizes errors. Efficient design means employees spend less time navigating the warehouse and more time completing tasks, ultimately driving productivity and cost savings.

7. What role does safety play in warehouse design?

Safety should always be a top priority. A good design minimizes hazards, includes emergency exits, clear signage, safe racking systems, proper lighting, and designated walkways. Prioritizing safety protects employees, reduces downtime, and improves morale and compliance.

8. How do I design a layout that supports business growth?

Create a flexible design by planning for modular shelving, scalable racking systems, and future expansion zones. Leave open areas for potential workflow changes and invest in adaptable storage solutions that evolve with your business needs.

9. What is the lean warehouse concept, and how can it help?

Lean warehousing focuses on eliminating waste, enhancing efficiency, and standardizing processes. Implementing lean techniques like 5S (Sort, Set in order, Shine, Standardize, Sustain) reduces unnecessary movement, improves workspace cleanliness, and ensures continuous improvement.

10. Should my warehouse layout be the same for all locations?

Not necessarily. Each warehouse should be designed considering its unique location, size, operations, and customer demands. While certain design principles can be standardized, layout specifics should be tailored to suit the function and volume of the specific facility.