Warehouses are the backbone of any supply chain. If operations inside a warehouse are running smoothly, then the rest of the business runs smoother. This is why businesses are employing WMS software these days to organize their inventory, monitor goods, and process orders quicker and more efficiently.

If you are looking to purchase a Warehouse Management System (WMS), this guide will inform you what it is, what are the features that count, and how to select the optimal one for your Indian warehouse.

What Is WMS Software

WMS stands for Warehouse Management System. It is a system that is used on computers to manage warehouse activities end-to-end.

In easy terms, it assists you in knowing:

What inventory you possess in your warehouse

Where every product is stored

When it has to be transferred, packed, or shipped

Here’s a brief overview of what a WMS does for your warehouse:

| Task | How WMS Helps |

| Receiving goods | Records items and locations automatically |

| Storing goods | Suggests best places for storage |

| Picking orders | Guides workers to exact product locations |

With WMS software, you can eliminate errors, save time, and optimize your warehouse.

Why Your Warehouse Needs WMS Software

A WMS makes your warehouse smarter and more precise. Here’s why it matters:

- You obtain real-time information regarding inventory.

- It cuts down on errors brought about by manual record-keeping.

- Your employees can find and ship products quicker.

- You can plan space and manage orders more effectively.

- It helps reduce costs and enhance customer satisfaction.

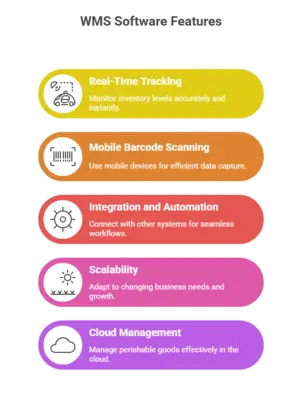

Key Features to Check When Choosing WMS Software

When you select a WMS software, ensure the features help in easy and quick day-to-day work.

- Real-Time Inventory Tracking

This is one of the most helpful features. It keeps your inventory data real-time every second. When you receive or pick or ship a product, the system automatically updates.

It eliminates confusion regarding what is in stock and what is not. - WMS Software with Mobile Barcode Scanning

Workers can use scanners or mobile devices instead of paper lists.

With WMS software with mobile barcode scanning, any product can be scanned and traced with ease.

Advantages:

No typing mistakes

Increased order picking speed

Improved product identification speed

Real-time inventory updates - Integration and Automation

The WMS software must integrate seamlessly with other applications such as ERP, CRM, or eCommerce platforms.

When systems are integrated, you have end-to-end visibility across departments.

Automation also assists by performing the same task over and over again automatically, for example, updating inventory levels or generating invoices. - Scalability

If your warehouse is expanding, your system should expand with it. A scalable WMS enables you to increase the number of users, warehouses, and product categories without having to get a new system. - Cloud Warehouse Management System for Perishable Goods

If you handle foodstuffs, pharmaceuticals, or any perishable item, this feature is crucial.

A cloud-based warehouse management system for perishable items assists you in:

Temperature and humidity monitoring

Expiry date tracking

Accessing information anywhere

Storing products fresh and secure

Warehouse Management System Pricing India

Most companies inquire about warehouse management system price India. Prices may differ based on what you’re looking for.

Here’s a basic comparison:

| Type | Cost Range (Approx) | Best For |

| Cloud-based WMS | ₹50,000 to ₹3,00,000 per year | Small and medium warehouses |

| On-premise WMS | ₹3,00,000 and above (one-time) | Large or complex operations |

Tip: Don’t simply search for the lowest price. Select a WMS that saves time, boosts accuracy, and minimizes long-term expenses.

Best WMS for High Volume Order Picking

If your warehouse receives hundreds or thousands of orders daily, you require a system that operates at a rapid pace.

The top WMS for high volume order picking features:

Wave or batch picking functionality to process multiple orders in batches

Real-time tracking so you know where all your orders are

Smart slotting that puts fast-moving products nearer the dispatch zones

Barcode confirmation to eliminate mistakes

Reports to track the performance of workers

This type of system prepares your warehouse for peak seasons and high volumes of orders.

How to Select the Ideal WMS Software

Selecting the proper WMS software requires preparation. Here are straightforward steps to follow:

Choosing the right WMS software takes planning. Follow these simple steps:

| Step | What to Do |

| Step 1 | Identify your warehouse challenges such as order delays or space issues |

| Step 2 | Decide if you need cloud-based or on-premise software |

| Step 3 | Check if the software can connect with your ERP or eCommerce platform |

| Step 4 | Ask for a demo to test the software |

| Step 5 | Check the quality of customer support and training |

| Step 6 | Choose a system that can grow with your business |

Involve your warehouse team at all times before making that final decision. They can inform you what will actually make their job simpler.

Why the Right WMS Software Matters

The correct WMS software benefits your business in several ways:

- Enhances inventory accuracy.

- Saves time since repetitive work is automated.

- Minimizes human errors.

- Makes customers happy with quick deliveries.

- Organizes your warehouse and improves productivity.

Without WMS, warehouses usually experience stock mismatches, delays, and disorganization. With it, your warehouse is efficient, clear, and easy to manage.

Conclusion

In this modern competitive era, warehouse management is not merely putting goods away. It is being smart while doing it. WMS software allows you to optimize inventory, space, and manpower to the best of your ability.

Be it cloud warehouse management system for perishable items or top WMS for high volume order picking, select a solution that aligns with your objectives, budget, and future growth plans.

When you research warehouse management system prices India, keep in mind that a good WMS is not a cost but an investment. It saves time, increases efficiency, and has your company prepared for the future.

FAQs (Frequently Asked Questions)

1. What are the initial steps to ready yourself for WMS implementation?

Begin by examining your existing warehouse procedure and sanitizing your data. Determine concise goals on what you wish to accomplish with the new system.

2. How much time is required to install a WMS software?

Installation requires four to twelve weeks based on the size of the warehouse as well as the requirement for customization.

3. Is WMS software capable of integrating with ERP and eCommerce CRM systems?

Yes, most contemporary WMS software is able to integrate with ERP and eCommerce CRM systems to facilitate seamless data exchange and improved coordination between activities. It also enables businesses to manage the advantages and disadvantages of E-Commerce CRM in a better manner.

4. How does WMS software enhance order accuracy?

It applies barcode scanning and automation to minimize picking, packing, and shipping errors.

5. Is a cloud WMS superior to an on-premise system?

Cloud WMS is simpler to access, maintain, and update, but on-premise systems provide greater data control. Select according to your business requirements.

6. What are typical pitfalls to watch out for when selecting WMS software?

Don’t select purely on cost. Consider scalability, integration capability, and adequate vendor support.

7. Does WMS software need employee training?

Yes, minimum training is necessary so your employees may use the software confidently and efficiently.