Shipping products safely to their destination is a crucial aspect of any business. Whether you’re shipping fragile items, heavy machinery, or electronics, shipping damage can result in financial losses, customer dissatisfaction, and even reputational harm. Understanding the causes of damage and implementing preventive measures can save businesses time and money while improving customer trust.

This guide will provide you with actionable strategies to minimize product damage, ensuring your products reach customers in pristine condition.

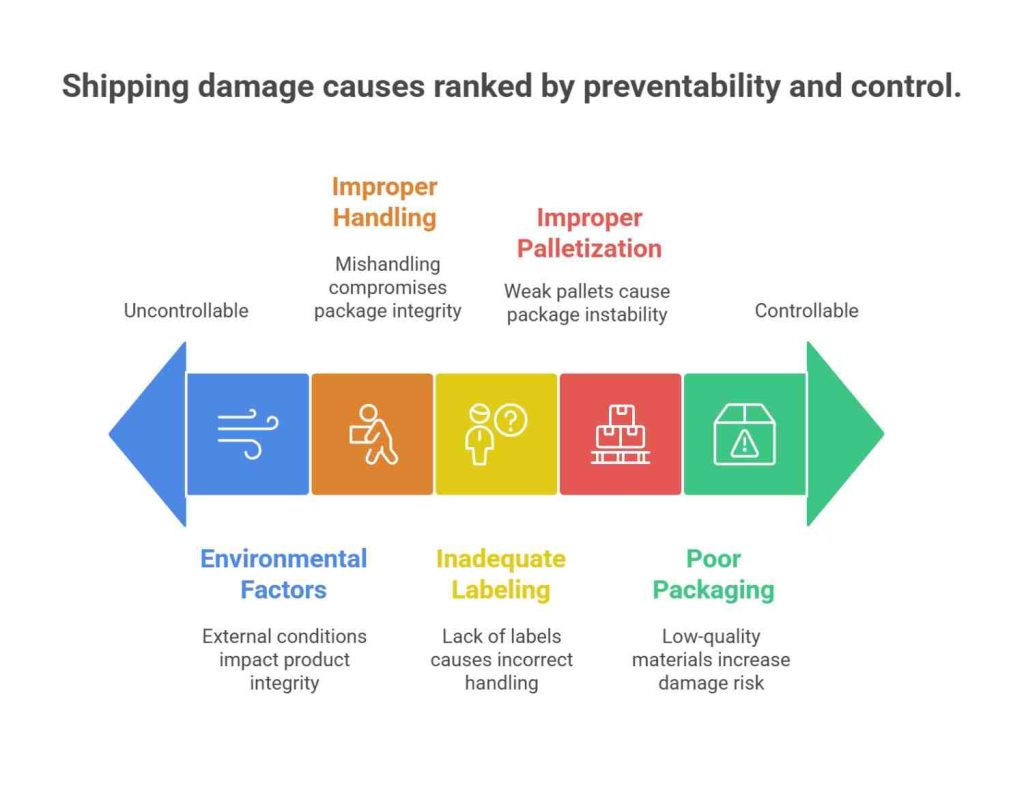

Common Causes of Shipping Damage

Before exploring solutions, it’s essential to understand why shipping damage occurs in the first place. Here are the possible reasons listed below:

1. Poor Packaging

- Using low-quality materials or incorrect box sizes increases the risk of damage.

- Insufficient cushioning can lead to product movement and impact damage.

2. Improper Handling

- Vendors stack packages in crowded areas ignoring the fragile item conditions.

- Mishandling at warehouses and shipping centres can compromise package integrity.

3. Inadequate Labeling

- Packages lacking proper “Fragile” or “This Side Up” labels are often handled incorrectly.

- Shipping personnel may not be aware of the sensitivity of certain items.

4. Environmental Factors

- Exposure to moisture, extreme temperatures, and humidity can affect product integrity. Products damaged during shipping

- Long shipping durations increase the risk of environmental damage.

5. Improper Palletization

- Overstacking or improper arrangement of boxes on pallets can cause shifting and damage.

- Weak or broken pallets contribute to package instability.

How to Prevent Shipping Damage? Best Practices

Implementing effective packaging and handling strategies can significantly reduce shipping damage. Here are the best practices to follow:

1. Choose the Right Packaging Materials

- Use sturdy corrugated boxes with double or triple walls for added protection.

- Select high-quality tape, bubble wrap, foam inserts, and air pillows to cushion fragile items.

- Ensure the package size fits the product snugly to prevent movement inside the box.

2. Use Proper Cushioning Techniques

- Wrap delicate items individually using bubble wrap or foam padding.

- Fill empty spaces with packing peanuts, air pillows, or crumpled paper to prevent shifting.

- For heavy items, consider using moulded foam inserts for added stability.

3. Reinforce Your Packaging

- Use heavy-duty packing tape to secure all seams and edges.

- Apply corner protectors for fragile or high-value items.

- Double-box fragile products for an extra layer of security.

4. Label Packages Clearly

- Use large, bold labels such as “Fragile,” “Handle with Care,” and “This Side Up.”

- Include handling instructions to guide shipping personnel. This can also help to lower shipping costs.

- Use waterproof labels to ensure they remain visible even in wet conditions.

5. Choose Reliable Shipping Partners

- Work with trusted carriers known for safe handling and timely deliveries.

- Use a shipping provider that offers tracking and insurance for added security.

- Communicate specific handling instructions with your carrier.

6. Optimise Palletisation for Bulk Shipments

- Stack boxes evenly and avoid overloading pallets.

- Secure pallets with stretch wrap and strong strapping.

- Arrange the heavier boxes at the bottom for better stability.

7. Use Shock and Impact Indicators

- Attach shock indicators or tilt sensors to monitor handling.

- This alerts recipients if improper handling occurs during transit.

8. Protect Against Environmental Factors

- Use moisture-resistant packaging for items susceptible to water damage.

- Consider temperature-controlled shipping for sensitive products like electronics or perishables.

- Vacuum-seal products when necessary to prevent air exposure.

9. Conduct Drop and Vibration Tests

- Test packaging durability by simulating drops and shakes.

- Adjust packaging design based on test results to minimize shipping damage.

10. Train Staff on Proper Packaging and Handling

- Educate employees on the importance of secure packaging techniques.

- Provide hands-on training on how to handle different types of shipments safely.

The Role of Technology in Preventing Shipping Damage

Technology plays a significant role in reducing product damage. Businesses can leverage modern tools and solutions such as:

- AI-Powered Package Optimization: AI algorithms analyze package dimensions and suggest the best materials and cushioning to reduce damage risk.

- Real-Time Tracking & IoT Sensors: Smart sensors monitor environmental conditions and package handling in real time. They are connected with different types of industrial labels to exchange information.

- Automated Packaging Machines: These machines ensure consistent and secure packaging, minimizing human error.

What to Do If Shipping Damage Occurs?

Despite all precautions, shipping damage may still happen occasionally. Here’s how to handle it effectively:

- Document the Damage: Upon receiving the damaged shipment, take clear photographs of the outer packaging, inner packaging, and the damaged product. This will serve as evidence for claims. Take note of all shipping damage indicators for future reference.

- Notify the Carrier Immediately: Contact the shipping provider and report the damage as soon as possible. Most carriers have a specific time frame within which claims must be filed.

- Keep All Packaging Materials: Do not discard the damaged packaging and materials, as the carrier may require them for inspection before processing the claim.

- File a Claim with Proper Documentation: If the shipment was insured, submit a damage claim with supporting evidence, including photos, invoices, and a written description of the damage.

- Contact the Supplier or Manufacturer: If the product was received from a supplier, notify them immediately so they can take corrective actions on their end.

- Offer Quick Resolutions to Customers: If you’re a business, prioritize customer satisfaction by providing replacements, refunds, or discounts to compensate for the damaged shipment.

- Analyze the Cause of Damage: Conduct an internal review to determine whether the damage was due to packaging errors, carrier mishandling, or other factors. Use this insight to refine your packaging and ship damage-control equipment to prevent future occurrences.

Conclusion

Preventing shipping damage requires a proactive approach, from selecting high-quality packaging materials to ensuring proper handling and leveraging technology. By implementing the strategies outlined in this guide, businesses can minimize losses, improve customer satisfaction, and ensure safe, damage-free deliveries. Investing in secure packaging and reliable shipping practices is not just a cost—it’s a necessity for long-term success.

By taking the right preventive measures, you can confidently ship products knowing they will reach their destination safely and intact. Do you need help to transform your supply chain traceability? Contact Qodenext today.

FAQs – Preventing Shipping Damage

1. What is the most effective way to prevent delivery damage?

Using high-quality packaging materials, proper cushioning, and working with reliable carriers significantly reduces the risk of last-mile delivery damage.

2. How can I protect fragile items during shipping?

Wrap fragile items individually, use double-boxing, and fill empty spaces with cushioning materials like bubble wrap or air pillows.

3. Is shipping insurance necessary?

Yes, especially for high-value or fragile items. Insurance covers costs in case of damage or loss.

4. What type of packaging is best for heavy shipments?

Use double-walled boxes, reinforced corners, and strong pallet strapping to secure heavy shipments.

5. How do I know if my packaging is strong enough?

Conduct drop tests and vibration tests to ensure your packaging can withstand handling and transit conditions.

6. What details are helpful when filing a damage claim?

Essential documentation includes photos of the damaged product and its packaging, proof of value (like invoices), a detailed written report of the damage, and all shipping labels. Keeping packaging is recommended until the claim is resolved.

7. Can specific shipping services help protect my products?

Yes—many carriers offer specialized services, such as fragile-item handling, temperature-controlled shipping for perishables, and extra insurance coverage. Selecting these helps ensure safer delivery, especially for sensitive goods.

8. Who is liable if my product arrives damaged—seller or courier?

Liability for shipping damage usually depends on the shipping agreement. If the damage occurs before the carrier receives the goods, the seller is often responsible. If the damage occurs during transit, the carrier may be liable. It’s important to check the terms of service and maintain full documentation for claims.

9. How can I monitor conditions during shipment?

You can use smart sensors and IoT devices to track factors like temperature, humidity, shock, and package tilt in real-time. These technologies provide alerts if a shipment encounters damaging conditions, helping you respond quickly to issues.

10. What types of shipping damage occur most frequently?

The most common types include physical impact (drops, crushing), water or moisture-related damage, temperature-induced damage, and mishandling. Proper packaging and route planning help minimize all of these.