Imagine a life-saving vaccine traveling halfway across the world, only to lose its potency because someone forgot to close a truck door properly.

Or a gourmet salmon shipment that arrives smelling anything but fresh. These aren’t isolated accidents – they’re frequent nightmares in cold chain logistics.

But today, there’s a high-tech ally quietly working behind the scenes: IoT in cold chain.

From pharmaceutical giants to food retailers, companies are now turning to Cold chain IoT technology to keep temperatures just right, assets visible, and risks minimized.

Let’s explore how this technology works, who’s already using it, and why the future of cold chains is getting smarter.

Why Cold Chains Need a Tech Upgrade

Cold chains are sensitive. A few degrees off, and you’ve lost an entire shipment. That’s where the Cold chain monitoring revolution powered by IoT comes in.

Here’s why the stakes are high:

- Spoilage risk: 1 in 3 vaccines is compromised due to temperature issues.

- Strict regulations: Compliance is becoming stricter globally (FDA, WHO, etc.)

- Customer expectations: Whether it’s medicine or meat, customers want quality, always.

Now that we’ve seen the why, let’s look at the how.

What Makes IoT in Cold Chain a Game-Changer

IoT-enabled cold storage isn’t just about adding sensors to a freezer. It’s about building a real-time, intelligent ecosystem that ensures precision.

Here’s how it works:

| Component | What it Does |

| Sensors | Measure temperature, humidity and vibrations |

| GPS devices | Track shipment locations in real time |

| Cloud Platforms | Aggregate data from across the chain |

| Alerts and Automation | Trigger actions if conditions deviate |

Think of it as a smart assistant riding shotgun with every shipment.

Example: Pfizer, during its COVID-19 vaccine distribution, used real-time temperature monitoring and GPS sensors to maintain ultra-cold storage from plant to patient. Any deviation would trigger alerts instantly – there was no room for guesswork.

Now that we understand the mechanics, let’s look at what’s changing in 2025 and beyond.

Smart Cold Chain Solutions: What’s New in 2025

Innovation is making cold chains smarter, cheaper, and more predictive. Here are the standout smart cold chain solutions we’re seeing:

- Edge AI at the container level: Sensors can now analyze and act without waiting for cloud input.

- Blockchain meets IoT: Tamper-proof cold chain records are helping in compliance.

- Battery-less IoT tags: Energy harvesting tags are cutting maintenance costs.

Example: Maersk is experimenting with AI-driven reefer containers that can self-adjust temperature based on location, weather forecasts, and cargo type.

Cool, right? But where exactly are these technologies making a mark?

Industries Leading the IoT Cold Chain Revolution

Cold chain logistics IoT is being embraced across industries. Let’s break it down:

| Industry | How They Use IoT |

| Pharmaceuticals | Track vaccines & insulin in real time |

| Food & Beverage | Monitor produce freshness from farm to store |

| Dairy & Meat | Detect spoilage risks early through shock/temp data |

| Retail | Automate shelf and safety compliance |

Example: Nestlé has partnered with IBM to use AI and IoT for food traceability across its dairy supply chains. With IoT sensors on milk tankers and processing facilities, they reduce spoilage by nearly 30%.

Now that we’ve seen the where, let’s talk implementation.

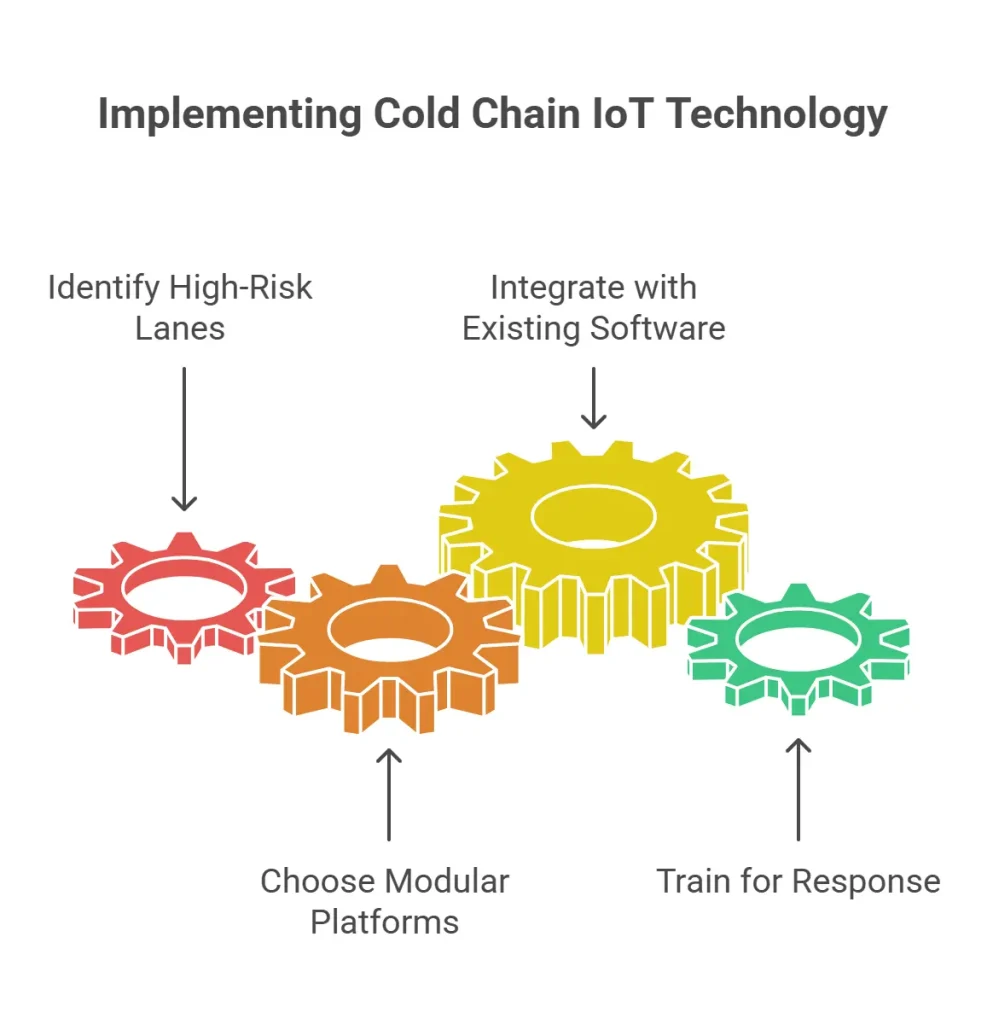

Implementing Cold Chain IoT Technology Without Losing Your Mind

Deploying IoT-enabled cold storage doesn’t mean rebuilding your entire supply chain. Here’s how you can do so:

- Start with the high-risk lanes: Pilot IoT in routes or products with the most spoilage or cost impact.

- Use modular platforms: Choose systems that allow for phased integration.

- Integrate with existing software: Your WMS or ERP can likely sync with IoT dashboards.

- Train for response, not just alerts: Data is only as good as the action it enables.

Example: Indian cold chain startup Tan90 offers solar-powered IoT boxes for rural vaccine transport – a perfect case of low-cost innovation meeting high impact.

What Makes This Shift So Important?

This isn’t just about avoiding spoilage. It’s about rethinking how we build responsive, adaptive, and sustainable cold chains.

- It helps brands build trust with transparency.

- It enables sustainability by reducing waste.

- It prepares logistics firms for future logistics where data drives every decision.

IoT in cold chain is not just nice-to-have. It’s the insurance policy modern supply chains can’t afford to skip.

FAQs: The Coolest Tech in Logistics: How IoT Is Transforming Cold Chains in 2025

1. Can cold chain IoT work in remote or rural areas with weak connectivity?

Yes, many IoT devices now use LPWAN (Low Power Wide Area Networks) or satellite communication to function in low-connectivity zones.

2. Is it possible to get real-time alerts even on a smartphone?

Absolutely. Most cold chain monitoring platforms come with mobile dashboards and alert systems via SMS, WhatsApp, or apps.

3. Are there sustainable options in cold chain IoT technology?

Yes, from solar-powered sensors to recyclable smart labels, companies are pushing for greener IoT hardware.

4. What’s the cost-benefit for small-scale operators?

Initial setup can be expensive, but reduced spoilage, fewer recalls, and better planning usually pay off within 6–12 months.

5. How are smart cold chains helping with carbon footprint?

Less spoilage = less waste. Efficient routes = less fuel. Predictive maintenance = longer asset life. All this reduces emissions.

Conclusion

Thanks to Cold chain IoT technology, we’re entering an era where supply chains are intelligent, connected, and deeply data-driven.

Whether it’s vaccines in Bangladesh, strawberries in California, or seafood from Japan – cold goods are safer, fresher, and better monitored than ever before. For businesses navigating future logistics, investing in smart cold chain solutions isn’t just a good idea – it’s mission-critical.