Gone are the days when price and availability alone drove supplier decisions.

In 2025, companies are prioritizing long-term partnerships, sustainability, and innovation. From raw materials to final delivery, managing supplier relationships strategically has become vital for agility, competitiveness, and resilience.

This blog explores why supplier relationship management matters now more than ever, how companies are optimizing their supplier agreement management process, and what supplier relationship management best practices they’re using to stay ahead.

Let’s get started.

What is Supplier Relationship Management and Why It’s Crucial Today

Supplier relationship management is the structured approach organizations use to engage, evaluate, and collaborate with suppliers to maximize value across the supply chain.

This includes:

- selecting the right partners

- setting performance expectations

- ensuring compliance

- and, fostering mutual growth

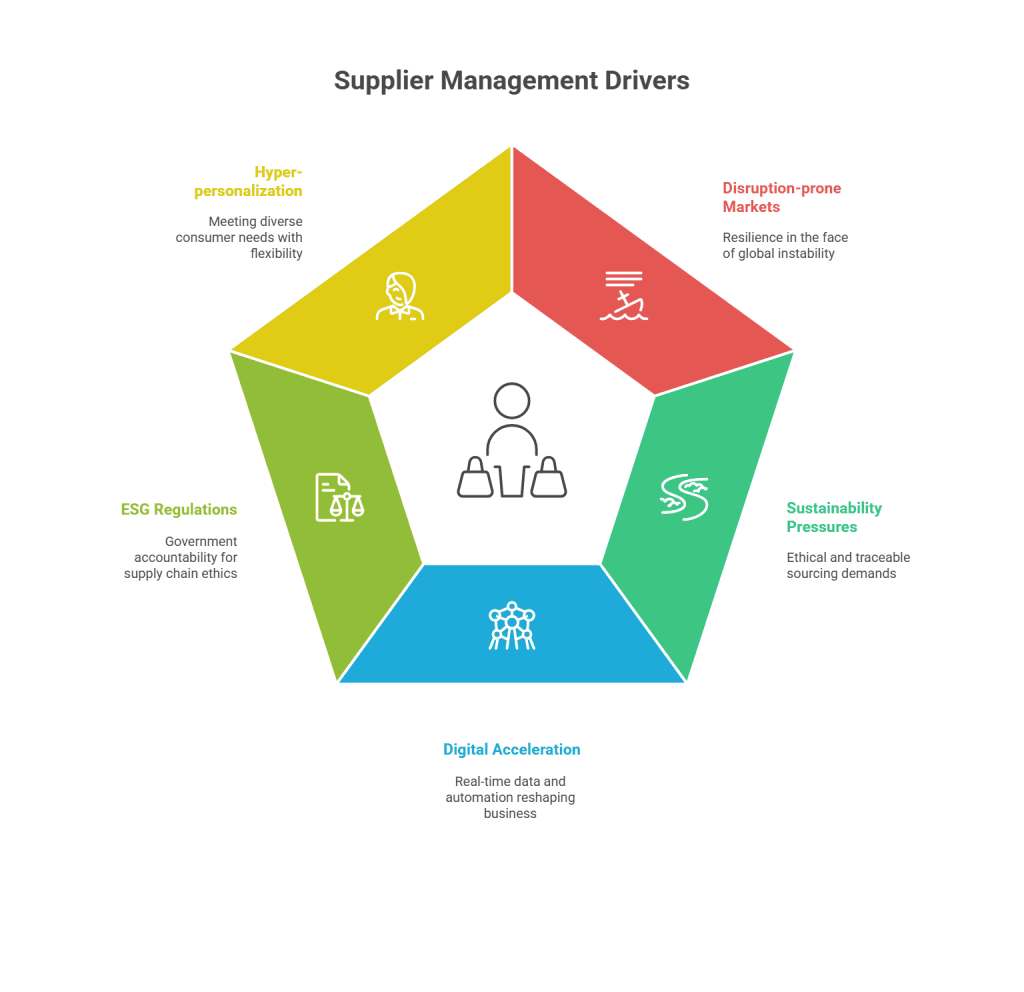

In 2025, five macro trends are driving the importance of supplier management:

- Disruption-prone markets: From geopolitical instability to pandemics, supply chains need resilient suppliers.

- Sustainability pressures: Customers demand traceable, ethical sourcing.

- Digital acceleration: Real-time data and automation are reshaping how businesses work with suppliers.

- ESG regulations: Governments are holding companies accountable for supply chain ethics.

- Hyper-personalization: Businesses require flexible and responsive suppliers to meet diverse consumer needs.

Let’s now explore how companies are embedding these realities into their supplier agreements.

The Growing Role of Supplier Agreement Management and Its Process

In 2025, static, one-size-fits-all contracts are outdated.

Businesses are embracing dynamic supplier agreement management systems to create flexible, responsive partnerships.

The modern supplier agreement management process includes:

- Digitized contracts with automated renewal alerts and real-time compliance tracking

- Performance-based terms linked to key KPIs like on-time delivery, ESG goals, and product innovation

- Built-in escalation procedures to resolve disputes quickly and fairly

- Collaborative clauses encouraging joint innovation, R&D, or risk-sharing

For instance, Unilever – one of the world’s largest FMCG companies, has embedded climate-related targets into its supplier contracts. Suppliers must report emissions and show continuous improvement, aligning Unilever’s sourcing with its net-zero roadmap.

Such contracts are no longer static documents; they are live tools that reinforce strategic alignment and accountability.

Now that we’ve laid the contractual foundation, let’s explore real-world strategies that top companies are using to maximize supplier value.

Effective Supplier Relationship Management Strategies for 2025

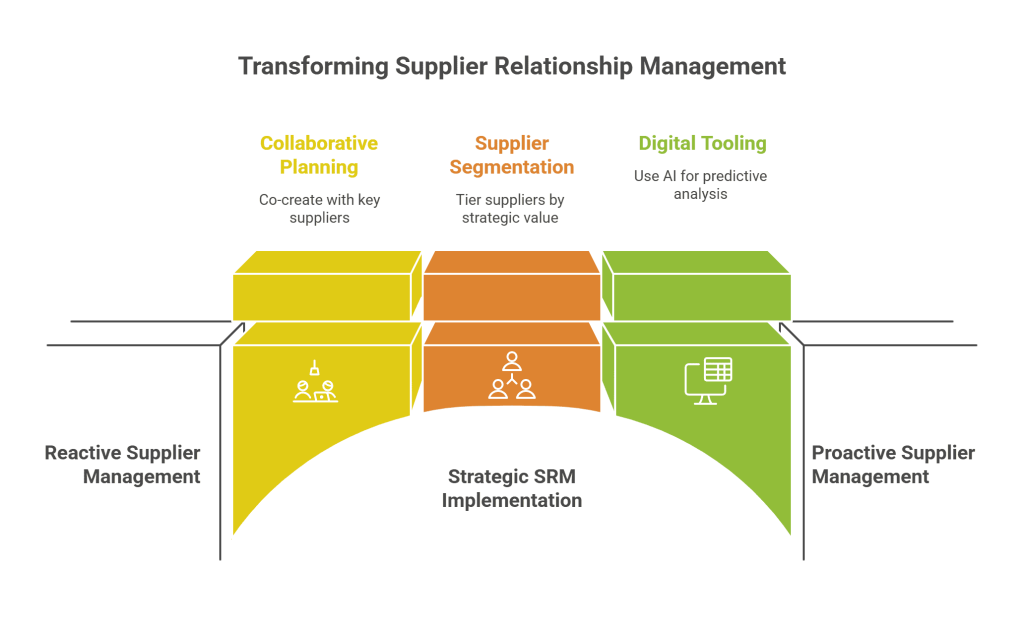

1. Collaborative Planning and Innovation

Today’s leaders aren’t just placing orders, they’re co-creating with suppliers. In 2025, supplier relationship management strategies are increasingly focused on collaboration during the earliest stages of planning and development.

Apple is a prime example. The tech giant works closely with suppliers like TSMC (Taiwan Semiconductor Manufacturing Company) not just for capacity but for chip-level innovation. By involving suppliers early in product development, Apple secures supply chain visibility, custom technology, and competitive edge.

This collaborative approach ensures suppliers are invested in innovation – not just compliance.

2. Segmenting Suppliers by Strategic Value

Another critical strategy is segmenting suppliers based on their role in business outcomes. Instead of managing all suppliers the same way, companies divide them into tiers: strategic, preferred, or transactional.

Take Toyota, for example. Their legendary keiretsu model is built on nurturing deep, long-term relationships with a select group of key suppliers. These suppliers are treated as partners, not vendors, and are involved in planning, development, and quality control.

This strategic segmentation allows Toyota to balance innovation and efficiency across its supplier base.

3. Leveraging Data and Digital Tools

Digital-first supplier management is now the norm. Companies are adopting SRM platforms powered by AI, machine learning, and predictive analytics to monitor supplier performance, risk exposure, and capacity trends.

Nike uses advanced analytics to assess and manage suppliers in real time, especially for sustainability compliance. By using data dashboards, Nike can flag environmental or labor-related risks early and work with suppliers to address them before they become reputational threats.

In short, data is transforming how businesses manage supplier relationships – from reactive troubleshooting to predictive decision-making.

Now that we’ve seen how real companies apply these strategies, let’s explore the best practices they follow to ensure sustainable success.

Supplier Relationship Management Best Practices

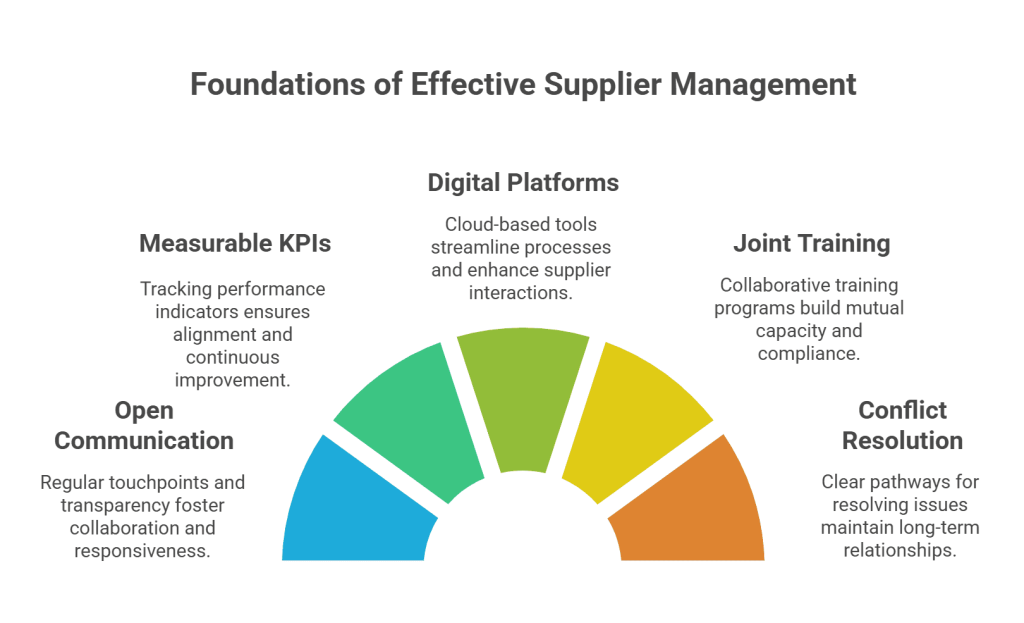

Effective supplier relationship management best practices go beyond tools and strategies – they’re rooted in trust, transparency, and alignment.

1. Open Communication and Regular Engagement

Set structured touchpoints (weekly calls, quarterly business reviews) to keep suppliers aligned and responsive. Transparency fosters collaboration, especially during disruptions.

2. Measurable KPIs and Feedback Loops

Define and track key performance indicators such as defect rates, lead times, and ESG compliance. Provide data-driven feedback and recognize high performers.

3. Digital Supplier Platforms

Use cloud-based SRM tools for onboarding, certification management, documentation, and supplier self-service portals. This reduces manual errors and improves responsiveness.

4. Joint Training and Development

Offer training programs to suppliers on quality standards, sustainability expectations, and regulatory compliance. This builds mutual capacity.

5. Fair and Clear Conflict Resolution

Include conflict resolution pathways in your supplier agreement management process to address issues constructively without damaging long-term relationships.

Amazon, for instance, uses supplier scorecards and quarterly reviews to ensure performance standards across thousands of vendors. High-performing suppliers are rewarded with more business, while those falling short are offered support before facing penalties.

These practices help companies build long-term supplier partnerships rooted in trust and accountability.

With strong processes in place, let’s now examine the critical role technology plays in managing supplier ecosystems.

The Role of Technology in Managing Supplier Relationships

Modern managing supplier relationships depends heavily on smart technology. Businesses are leveraging cloud platforms, AI, IoT, and blockchain to streamline operations and mitigate risk.

Here’s how:

- AI for predictive analysis: Anticipate supplier disruptions, demand shifts, or quality issues

- Blockchain for traceability: Ensure transparent sourcing, critical for ethical and regulated industries

- Supplier portals: Enable real-time communication, document exchange, and self-service workflows

- Cloud-based SRM systems: Centralize data, automate approvals, track compliance, and flag risks

For example, Nestlé uses blockchain to trace ingredients across the food supply chain, ensuring ethical sourcing and rapid issue resolution. The digital ledger improves trust with both suppliers and customers.

Clearly, the intersection of technology and SRM is transforming how businesses operate – from tactical to strategic.

FAQs : Strategies Big Brands Use to Manage Supplier Relationships

1. What makes SRM more critical in 2025 than before?

Rising complexity, ESG compliance, and real-time expectations make supplier relationship management essential for business continuity.

2. How do global leaders use supplier segmentation?

They group suppliers by value – strategic partners get deeper collaboration, while transactional vendors follow standardized processes.

3. What’s the difference between contract management and SRM?

Supplier agreement management is part of SRM. SRM includes ongoing performance tracking, risk management, and strategic alignment beyond contracts.

4. How does digital SRM improve supplier performance?

It offers real-time visibility, automates compliance checks, and flags issues early – allowing faster, smarter decisions.

5. Can small businesses benefit from supplier relationship strategies?

Absolutely. Even small companies can use cloud SRM tools, set clear expectations, and build loyalty through proactive engagement.

Conclusion

In a world where resilience, agility, and sustainability define winners, supplier relationship management is no longer a back-office function. It’s a boardroom priority.

Whether you’re a growing business or a global enterprise, investing in how you manage supplier relationships today will shape your ability to compete tomorrow.