A sorting centre is a facility for organising and distributing items efficiently based on factors like destination or type. It serves as a hub where incoming shipments or packages go through processing, sorting and preparation for onward transportation or delivery.

Typically equipped with advanced technology and conveyor systems, such centres streamline the handling process, ensuring timely and accurate distribution. They play a crucial role in logistic networks, optimising the flow of goods and enhancing overall supply chain operations.

Sorting Center Meaning

A sorting center is a facility where packages and shipments are received, scanned, and organised before moving to their next stop. Think of it as a hub in the logistics chain that ensures parcels are directed to the right destination quickly and accurately. Unlike warehouses that mainly store goods, a sorting center focuses on the fast processing and redistribution of items to keep deliveries on schedule.

Sorting Process

The sorting process begins when shipments arrive at the sorting center. First, packages are scanned and verified, then grouped based on factors like size, destination, or postal code. After that, labels are attached or updated for accuracy. Finally, items are dispatched to the right route—whether that’s another sorting facility or directly toward the customer. This streamlined process reduces errors, speeds up deliveries, and ensures customers get their orders on time.

What is the Use of Sorting?

Sorting serves as a fundamental process in various industries, facilitating the organisation and categorization of items based on predetermined criteria such as destination, size, or type. It

- Optimises logistical operations by streamlining the handling and distribution of goods

- Ensures timely delivery and efficient utilisation of resources.

- Enhances workflow efficiency in transportation, manufacturing, or e-commerce

- Minimises errors, and

- Improves customer satisfaction

It does so by ensuring that items reach their intended destinations accurately and promptly.

Sorting Centre for Inbound and Outbound Centre

For inbound receiving, you would need to sort if the goods do not have proper arrangements when they come to the warehouse. For instance, receiving deliveries from overseas containers. Another instance could be receiving many items but in small quantities. The warehouse workers must sort them out by item before putting them in a storage location.

In the case of outbound, sorting is necessary if the warehouse which does batch picking (has multiple orders) gets selected together. Then the warehouse operative sorts them according to the correct respective individual order.

Once the sorting is complete, the warehouse professional will pack the sorted order and attach a shipping label to it. This process of sorting centres applies to an eCommerce business.

Let’s see how the items move inside the warehouse.

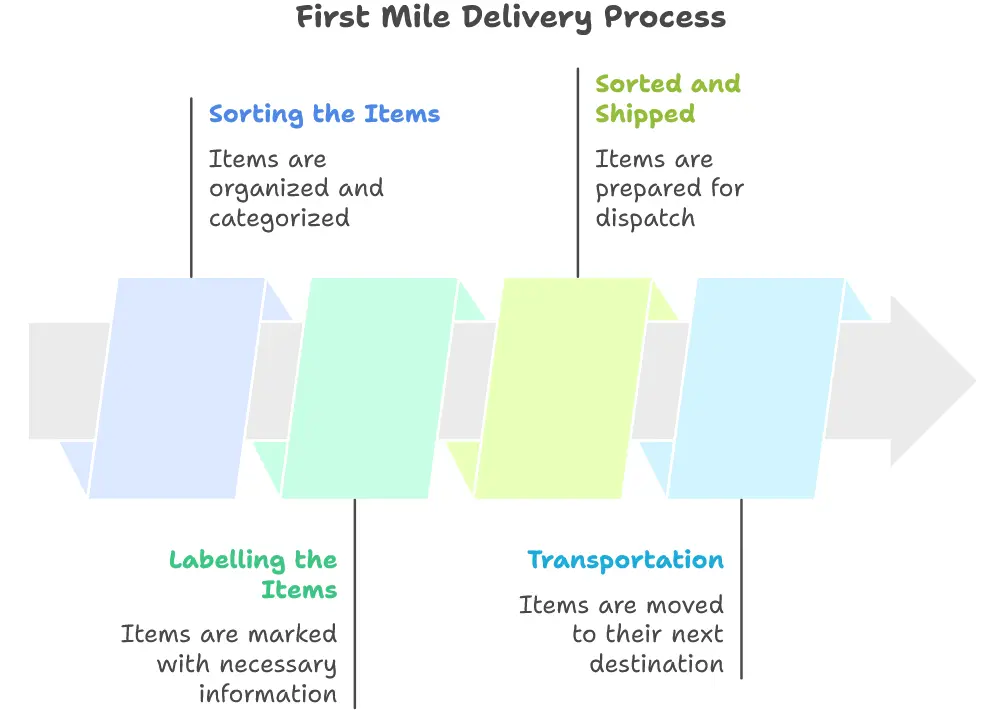

First Mile Delivery: Shipping the Items to the Next Destination After the Warehouse in the Supply Chain

Delivering shipments to first-mile sorting facilities happens in several steps. This ensures that the materials have efficient sorting and delivery to the correct destination.

So, what is sorting?:

Sorting the Items: When packages arrive at the sorting facility, the workers organise them depending on their size or delivery address. After this initial sorting, the items are ready to go through the next steps of handling and distribution.

Labelling the Items: There is additional labelling from the sorting centre to ensure that every package has all the required information on it. This is important for accurate delivery and tracking.

Sorted and Shipped: The items then move to their final destination. This happens after they go through processing and are marked. Depending on the route and mailing address, the packages can reach the next sorting facility or their final destination.

Transportation: The duration of the first-mile shipment can vary depending on the availability of the truck, distance and more supply chain activities.

Businesses will be able to streamline their shipping procedures by sorting items at the first-mile facility.

Next, we will see what happens inside the sorting centre.

Activities Inside the Sorting Centre

The sorting facility makes it easier to deliver products to consumers on time. This boosts client satisfaction and success. There are several crucial procedures that the facility staff perform to facilitate accurate processing, like:

- Receiving: When the goods reach the sorting facility, they undergo a thorough inspection to ensure they match with the order information. The staff also detects any damage that may have happened during transit.

- Storage: As long as the items stay at the centre, employees in charge of keeping inventory records ensure the security of the products they store. To avoid spoiling, personnel give extra care to temperature-sensitive goods. Personnel make the best efforts to ensure shipment has a convenient location in the facility.

- Picking, Packing and Labelling: The employees pick the items and pack them. Then they attach the labels on them so they are ready for shipping or delivery.

This sorting system warehouse measures offer supply chains many benefits. Sometimes all these processes have automation. Using automation for inbound sorting centres streamlines the process. It saves time and money and more. What to know how? See below.

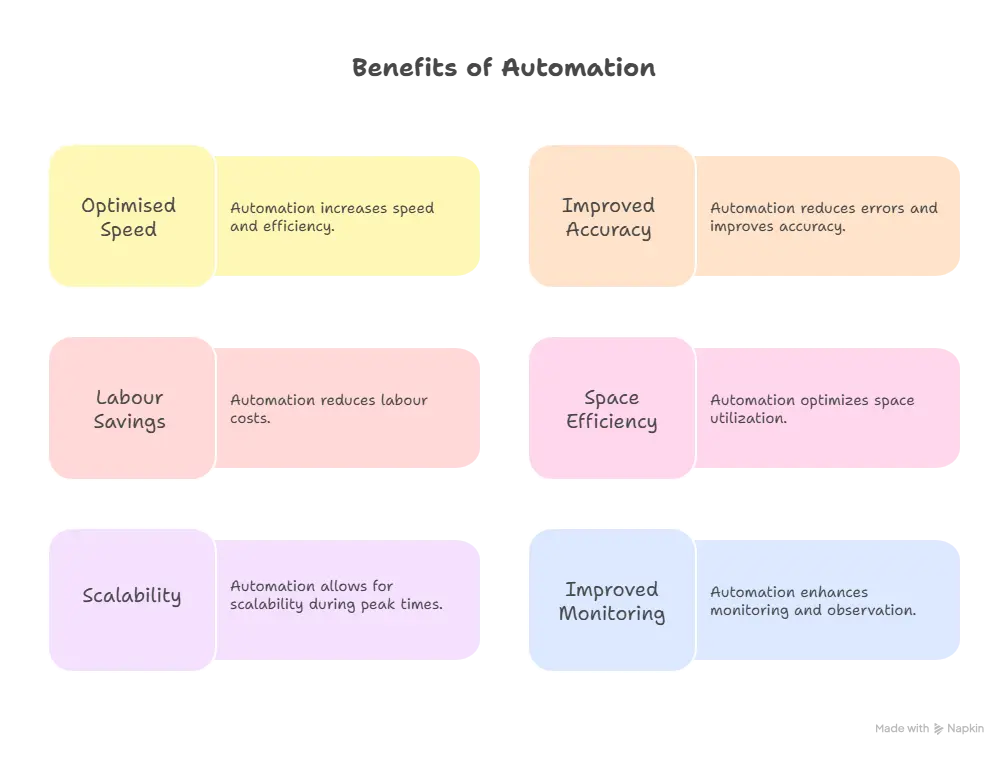

6 Advantages of Automating Sorting Centres

Let’s delve into the advantages that automation brings to these crucial facilities, revolutionising efficiency and optimising logistics operations.

1. Optimised Speed and Efficiency

The sorting procedures are streamlined by automation technologies. They minimise delays and manual processing. Owing to this efficiency, processing times are short. This ensures that the packages travel through the sorting facility as intended and reach their destinations on time.

2. Improved Accuracy

Automation also enhances the accuracy of delivery. It reduces errors that include misreads or misplacement. It also guarantees that every package is accurately sorted and goes to the right location.

3. Labour Savings

In comparison to manual sorting techniques, automated sorting systems do not require as much human interaction. Since there are free labour-intensive activities needed, it may reduce worker size and save considerable money on labour costs.

4. Space Efficiency

Automated sorting systems optimise the utilisation of available space in sorting facilities, efficiently processing numerous packages through advanced algorithms and minimal equipment, thereby maximising spatial efficiency.

5. Scalability in Peak Times

During peak times like holidays or promotional events, sorting facilities can accommodate more parcels with the help of an automated system. As they achieve scalability, the facility can continue to run efficiently during heavy demand periods. This helps them to avoid delays and service disruptions.

6. Improved Monitoring and Observation

Automation makes real-time monitoring possible. This allows recipients and service providers to monitor the location and status of packages effectively. Transparency and communication can improve due to increased visibility.

Have you wondered how long the package stays at the facility? Let’s quench this curiosity of yours.

Duration of a Package’s Stay in the Sorting Warehouse

Once your package arrives at the sorting facility, it can stay there for a few hours or days. It depends on several factors like the shipping method you have chosen, the workload of the centre and the number of workers available.

If you opt for faster shipping it means you need quicker sorting. However, a busy centre means there might be a slight delay in your package. These conditions determine how long your cargo will stay at the sorting facility. More active centres and slower shipping methods may result in longer wait times for your package.

Tips for Sorting Warehouse

Here is what you can do:

- Sorting is crucial for warehouse organisation, aiding in efficient product retrieval and shipping.

- Manual sorting is costlier and slower compared to automated methods.

- Popular sorting machines include conveyor belts and barcode sorters.

- Proper sorting is essential for smooth warehouse processes.

- Utilise appropriate sorters and invest in quality sorting software for efficiency.

- Prioritise popular products for easy access.

- Understand and optimise the entire sorting process to minimise travel times.

- Enhance ergonomics and provide proper tools for staff.

- Utilise technology and software to improve sorting strategies, especially during peak seasons.

- Ensure synchronisation between ERP and WMS systems for streamlined operations.

Incorporating these tips into your warehouse sorting process will enhance efficiency, reduce errors, and optimise operations, ensuring smooth order fulfilment and improved overall performance.

Conclusion

Now you understand why sorting is important. Sorting centres play a pivotal role in the logistics landscape, ensuring efficient handling and distribution of goods. To optimise operations, streamline workflows, and maintain accuracy during peak demand, consider partnering with Qodenext for expert solutions in supply chain management.

FAQs: Navigating Sorting Centres: Logistics Unveiled

1. What is a sorting centre in logistics?

A sorting centre is a hub where parcels and packages are scanned, organized, and directed toward their final destination. It ensures faster, more accurate, and cost-effective deliveries.

2. Why are sorting centres important in supply chain management?

Sorting centres streamline the shipping process by reducing delivery time, cutting transportation costs, and improving order accuracy—making them essential in modern supply chains.

3. How does a sorting centre work?

When packages arrive, they are scanned, sorted by destination or postal code using automated systems, and then dispatched to the next delivery hub or directly to the customer.

4. What is the difference between a warehouse and a sorting centre?

A warehouse stores goods for inventory management, while a sorting centre focuses on processing and redistributing parcels quickly to ensure timely deliveries.

5. Can I track my package at a sorting centre?

Yes. Most courier companies update the tracking system whenever a parcel enters or leaves a sorting centre, allowing customers to monitor delivery progress in real time.What does dispatch from the sorting centre mean?

6.Which is the best type of sorting?

The best and most efficient way of sorting goods is the partition method. It is faster than the other algorithms as it uses the concept of “divide and conquer”.

7.How do sorting facilities help in peak times of demand?

Sorting facilities manage peak demand by optimising workflows, adjusting staffing levels, and utilising technology to handle increased volumes efficiently while maintaining accuracy and timely delivery.

8. How long does a package stay at a sorting center?

A package may remain at a sorting centre for a few hours to a few days, depending on factors such as shipping method, centre workload, and operational efficiency. Faster shipping options usually mean shorter stays, while high-demand periods or limited workforce can cause slight delays.

9. What are the main advantages of automating sorting centers?

Automating sorting centres boosts speed, accuracy, and efficiency by minimising manual handling. It reduces labour costs, optimises space usage, enables real-time tracking, and ensures scalability during peak seasons—resulting in faster deliveries and higher customer satisfaction.

10. What technologies are commonly used in modern sorting centers?

Modern sorting centres use conveyor systems, barcode and RFID scanners, automated guided vehicles (AGVs), and advanced warehouse management software (WMS). These technologies work together to streamline sorting, improve accuracy, and enhance visibility across the logistics chain.