As Indian warehouses rapidly embrace logistics automation, the spotlight is firmly on automated guided vehicles (AGVs).

These driverless movers promise efficiency, speed, and safety, but deploying them isn’t as simple as placing bots on the floor. From the layout to workforce training, every aspect needs to be reimagined.

In this blog, we’ll unpack five practical, India-specific tips for deploying AGV systems and highlight how global and local companies are making it work.

Let’s get started.

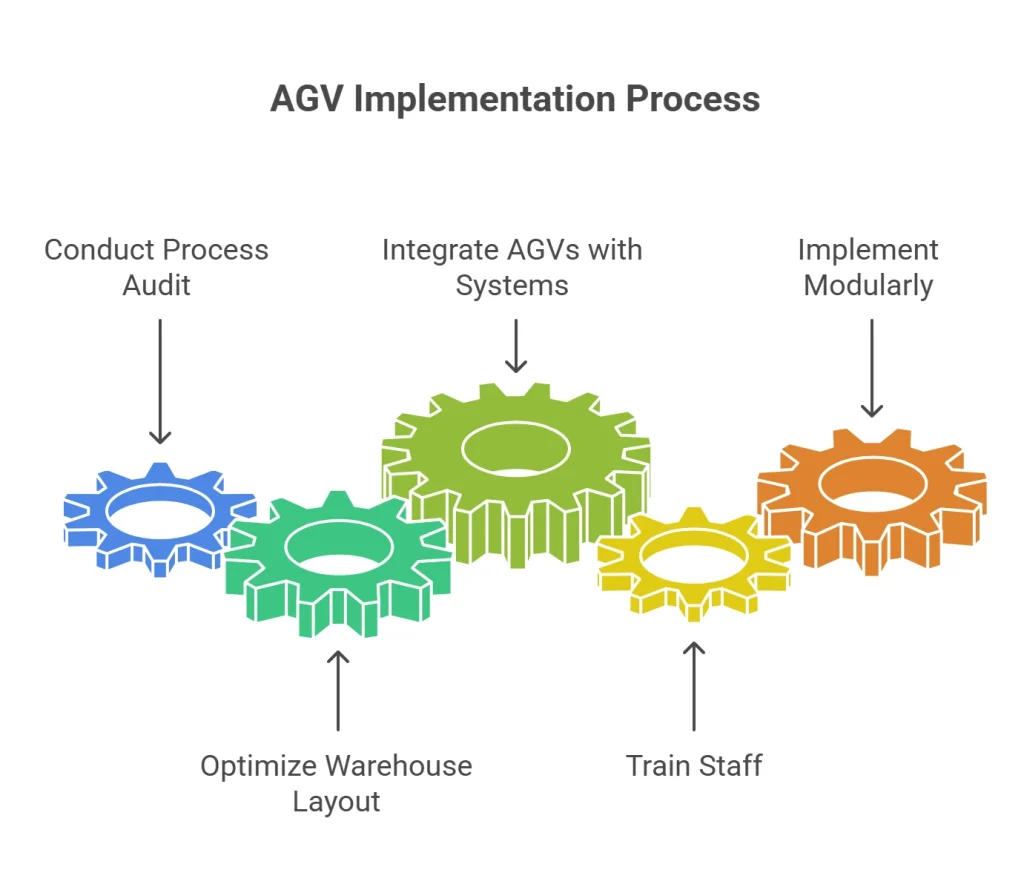

1. Start with a Process Audit, Not a Purchase Order

Before investing in shiny new AGVs, step back.

Do a warehouse process audit. Understand where the inefficiencies lie, what movement patterns dominate, and which activities are repetitive. Not all Indian warehouses are AGV-ready, especially with legacy infrastructure.

Why it matters:

- Helps identify areas where AGVs will genuinely add value.

- Avoids spending on unnecessary or mismatched systems.

Example: Flipkart’s automated sortation centers began with time-motion studies before onboarding their first AGVs. This helped them build AGV paths that complemented – not complicated – existing workflows.

Now that we’ve identified the need for a process audit, let’s explore how your physical warehouse design affects AGV success.

2. Your Layout Needs to Talk to Your Bots

Unlike forklifts, AGVs follow pre-defined routes using sensors, QR codes, or vision systems. That means narrow aisles, blind turns, or poor lighting can derail performance.

AGV warehouse readiness includes:

- Clear and wide navigation lanes

- No loose wires or cables on the ground

- Consistent floor quality

- High-contrast markings or QR codes

Tip: Consider hybrid systems like combining manual zones with AGV corridors.

Example: Amazon India’s fulfillment centers integrate AGVs only in selected zones while keeping others manually operated, ensuring balance and scalability.

So once your layout is ready to roll, how do you ensure your AGVs don’t get lost – literally? Let’s talk software and systems.

3. Integrate Your AGVs into Your Digital Ecosystem

AGV implementation doesn’t stop at buying hardware.

You need software that syncs AGVs with your Warehouse Management System (WMS), ERP, and IoT sensors.

Why software integration matters:

- Real-time inventory tracking

- Dynamic routing of AGVs

- Downtime alerts and remote diagnostics

Watch out for:

- Buying AGVs without open APIs

- Lack of in-house IT capacity to manage integrations

Example: TVS Supply Chain Solutions uses IoT-linked AGVs that sync with their digital twin platform to simulate warehouse operations and pre-empt issues.

You’ve built the track and the traffic system. But what about the drivers or rather, the people?

4. Train Staff Before, Not After, AGVs Arrive

Often, companies think AGVs replace workers. In reality, they shift job roles from operators to supervisors or technicians. That means retraining is key.

Steps to ensure workforce buy-in:

- Conduct hands-on training sessions

- Explain how AGVs improve safety and reduce physical strain

- Create troubleshooting SOPs for AGV halts or errors

Example: Tata Motors’ Pune plant saw a smooth AGV rollout after upskilling workers through simulation-based training.

With your people ready and systems set, let’s tackle the final frontier scalability.

5. Think Modular, Not Massive

A common mistake in AGV implementation is going all-in from day one. Instead, begin with a pilot, test it in one zone, measure results, refine, then scale.

Why modular deployment works:

- Easy to pivot based on learnings

- Reduced financial risk

- Better vendor accountability

Example: Reliance Retail started AGVs in its high-throughput DCs and expanded gradually based on ROI tracking.

Why AGVs Make Sense in India

India’s warehousing sector is undergoing rapid formalization. Labor shortages, rising throughput expectations, and real-estate constraints make automated guided vehicles a smart bet.

They’re ideal for:

- E-commerce fulfillment

- Automotive manufacturing

- FMCG and pharma cold chains

With costs decreasing and Indian startups entering the AGV space, we’re at an inflection point.

But remember: deploying AGV systems isn’t a plug-and-play solution. It’s a strategic transformation. One that requires change management, systems thinking, and long-term vision.

FAQs : 5 Smart Tips for AGV Implementation in Indian Warehouses

1. What types of AGVs are best suited for Indian warehouses?

AGVs like tow-vehicles, unit-load carriers, and forklifts are suitable depending on the industry. Compact, low-height AGVs are often preferred due to Indian warehouse constraints.

2. How long does it take to complete an AGV implementation?

A pilot deployment can take 3–6 months depending on integration needs and warehouse complexity. Full-scale rollouts may take up to a year.

3. Can AGVs handle variable Indian power conditions and connectivity?

Yes, modern AGVs come with power backup, 4G/5G compatibility, and offline navigation support to work in fluctuating environments.

4. What are the common challenges faced during AGV deployment in Indian warehouses?

Challenges include adapting AGVs to existing legacy infrastructure, ensuring reliable network connectivity across large or complex layouts, handling frequent power fluctuations, staff resistance to change, and integrating AGV systems with traditional warehouse management software.

5. How can safety be ensured when AGVs operate alongside human workers?

Safety is managed through high-visibility markings, physical barriers in shared zones, advanced AGV sensors (like LiDAR and cameras), and staff training on AGV awareness. Most AGVs are equipped with emergency stop features, collision avoidance, and audible alerts to ensure a safe working environment.

6. What maintenance do AGVs require in typical Indian conditions?

Routine maintenance includes battery checks and charging, wheel and sensor cleaning (especially important in dusty warehouses), periodic software updates, and quick-response support in case of breakdowns or errors. A local support team or on-site maintenance contract is recommended.

7. Are AGVs suitable for temperature-controlled or cold chain warehouses?

Yes, many AGV models are designed for use in refrigerated or cold-chain environments. It’s important to select AGVs with components rated for low temperatures and to ensure batteries and sensors can function reliably in these conditions.

Conclusion

Deploying AGV technology in Indian warehouses isn’t about jumping on a tech trend, it’s about solving real, everyday problems with smart automation.

From floor layouts to staff retraining and modular rollouts, success lies in careful orchestration.

As India’s logistics sector matures, expect to see more AGV warehouse integrations – from Tier 1 cities to emerging hubs. And if you start small but smart, you’ll be ready to scale fast when the time is right.