In a hyperconnected and demand-driven marketplace, packaging is no longer just about protection or aesthetics. It’s about efficiency, intelligence, and integration. This is where smart packaging solutions powered by AI-integrated ERP systems are transforming the supply chain, one package at a time.

From real-time tracking to predictive maintenance and customer personalization, smart packaging is enabling businesses to optimize logistics, reduce waste, and deliver better user experiences. At the heart of this evolution is the marriage of advanced ERP systems with artificial intelligence.

What Are Smart Packaging Solutions?

Smart packaging refers to intelligent packaging systems that incorporate digital technologies like sensors, RFID, QR codes, and connectivity to enable real-time tracking, data generation, and automation.

But smart packaging is not just about the hardware. The true value is unlocked when this data is fed into an ERP (Enterprise Resource Planning) system that can analyse, predict, and optimise operations. When ERP systems are infused with AI, they become capable of transforming static packaging into dynamic tools of visibility, analytics, and control.

How AI-Integrated ERP Enhances Smart Packaging Solutions

1. Real-Time Monitoring and Traceability

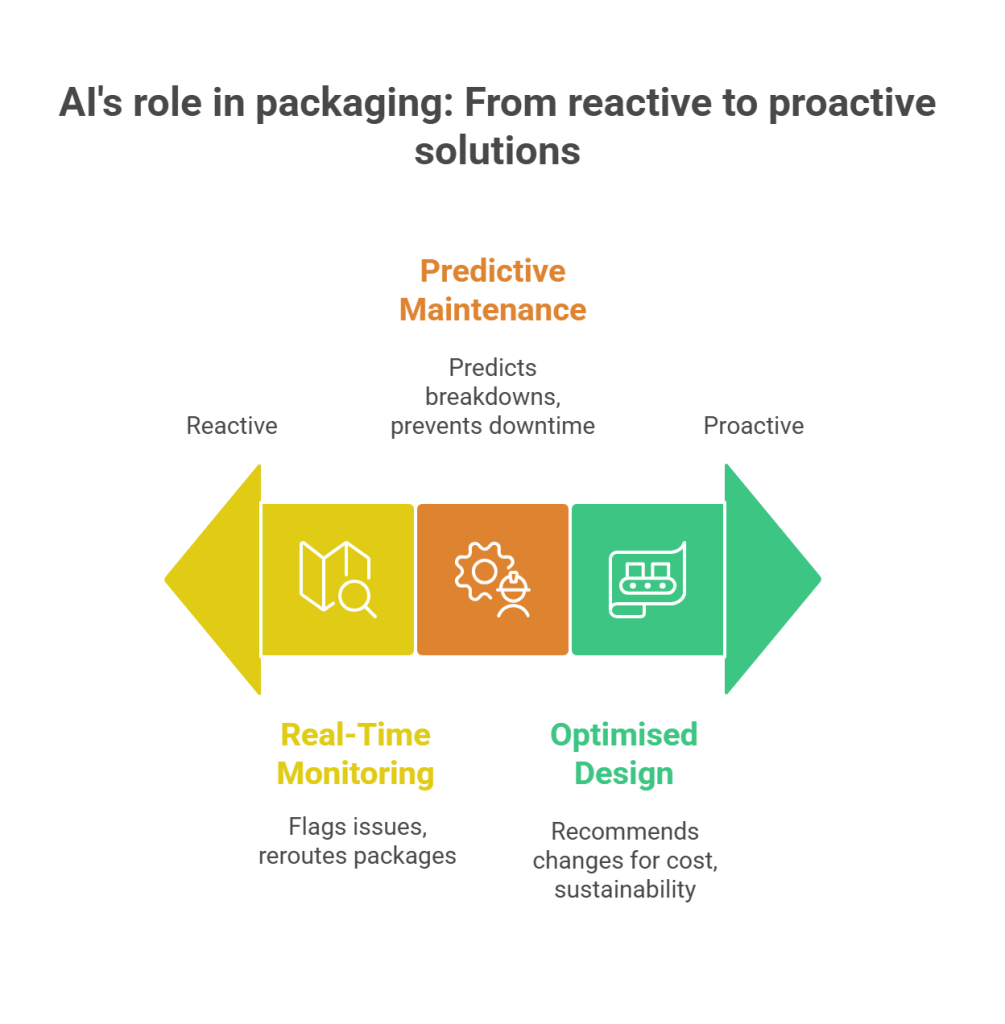

One of the biggest challenges in global logistics is the lack of transparency in package movement. With smart packaging solutions, AI-integrated ERP systems can collect and analyze data in real time from GPS sensors, RFID tags, and IoT devices embedded in the packaging.

For example, if a shipment is delayed or diverted, the ERP system instantly flags the issue and reroutes the package to its destination using AI-based decision-making. This minimises manual intervention, improves accountability, and enhances customer satisfaction.

2. Predictive Maintenance for Packaging Equipment

Packaging lines often face downtime due to unplanned maintenance or technical failures. AI algorithms in ERP for packaging can monitor equipment performance, identify wear-and-tear patterns, and predict when a machine is likely to break down.

This predictive maintenance enhances operational management, ensuring that ERP integration for logistics is consistently delivered without bottlenecks or delays.

3. Optimised Packaging Design

AI-powered ERP systems can analyze historical data related to shipment damage, handling times, and delivery conditions. Using this data, the system can recommend changes to packaging materials, dimensions, or even structural integrity.

This leads to packaging that is not just smart, but also optimised for cost, sustainability, and durability—core elements of modern smart packaging solutions.

Industry Applications

1. Food & Beverage

Perishable items benefit greatly from smart packaging solutions. Sensors can detect temperature variations, expiration dates, and freshness indicators, transmitting this information back to an ERP system for timely alerts or recalls.

2. Pharmaceuticals

With strict compliance needs, pharmaceutical companies are integrating AI with ERP systems to track medications through serialized packaging. This ensures authenticity, traceability, and adherence to regulations like DSCSA or FMD.

3. E-commerce & Retail

Retailers use smart AI solutions to track returns, analyze consumer behavior, and offer personalized discounts through QR-enabled packaging—data which is processed through AI-powered ERP dashboards for actionable business insights.

Benefits of Smart Packaging with AI-ERP Integration

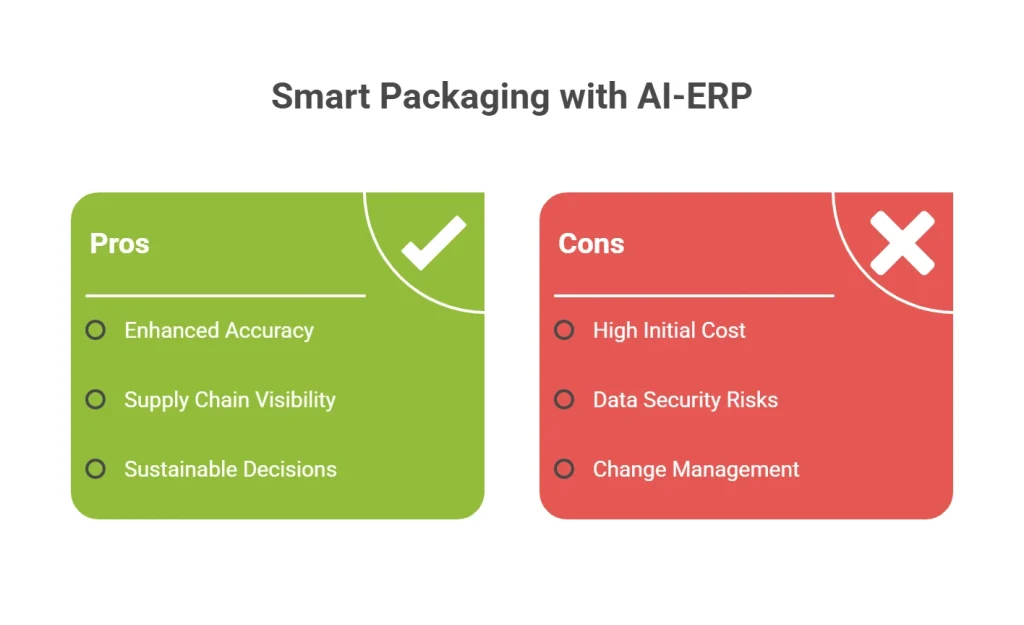

1. Enhanced Inventory Accuracy

When packaging is smart and connected to an ERP system, inventory levels are updated in real time. As soon as a package is scanned or shipped, the system adjusts stock levels automatically, reducing errors caused by manual entries.

This leads to accurate forecasting, better planning, and lower chances of stockouts or overstocking.

2. Streamlined Supply Chain Visibility

AI-enabled ERP systems offer end-to-end visibility—from packaging to the end customer. Managers can track the movement of goods, monitor delays, and even receive alerts for tampering or exposure to unsafe conditions (like temperature or humidity).

This 360° view is a hallmark of AI-driven ERP packaging, giving businesses the confidence and control they need in an uncertain logistics environment.

3. Sustainable Packaging Decisions

Sustainability is no longer optional; it’s a priority. ERP systems powered by AI can analyse carbon footprints, material waste, and energy consumption involved in packaging operations. Based on these insights, companies can pivot toward biodegradable materials, reduce excess packaging, or redesign packaging with circular economy principles.

These insights make smart packaging both eco-friendly and economically viable.

Challenges and Considerations – AI-Driven ERP Packaging

While packaging automation ERP solutions offer immense value, implementing them isn’t without challenges:

1. Cost of Initial Setup

Smart packaging hardware (sensors, RFID) and ERP integration may demand significant investment, particularly for SMBs.

2. Data Security

With increased data exchange between packaging and ERP systems, companies must invest in cybersecurity to prevent breaches.

3. Change Management

Teams need training to understand and use new AI-powered ERP workflows. Organisational buy-in is critical.

However, businesses that overcome these hurdles stand to gain a competitive edge through improved efficiency, customer loyalty, and long-term cost savings.

The Future of Packaging Automation ERP

The future points toward deeper personalization and automation. AI-driven ERP systems may soon enable dynamic pricing, automated restocking, and AI chatbots printed as QR codes on packaging, offering real-time customer service.

Moreover, with advancements in blockchain, smart packaging solutions could ensure tamper-proof, decentralized records, especially vital for pharmaceuticals, luxury goods, and sensitive electronics.

As AI models get smarter and ERP systems become more intuitive, the synergy between tech and packaging will only grow stronger. Businesses not investing in this evolution risk being left behind in an era defined by data-driven efficiency.

FAQs – Smart Packaging Solutions

1. What exactly is smart packaging?

Smart packaging refers to packaging systems equipped with technologies like sensors, RFID, and connectivity that provide real-time tracking, data sharing, and automation capabilities. These solutions often work in tandem with ERP systems for optimised operations.

2. How does AI improve smart packaging?

AI analyses real-time and historical data to predict delays, improve design, enhance traceability, and automate inventory decisions, making smart packaging more efficient and responsive.

3. Are AI in ERP systems expensive to implement?

Initial costs can be high, especially for hardware and ERP integration. However, the long-term savings in reduced waste, fewer returns, and improved operations typically outweigh the investment.

4. Which industries benefit the most from these solutions?

Industries like food and beverage, pharmaceuticals, retail, and e-commerce benefit the most due to the need for traceability, compliance, and real-time visibility.

5. Can small businesses adopt AI-integrated smart packaging?

Yes. Cloud-based ERP systems and affordable sensor technology are making smart solutions increasingly accessible to small and medium-sized businesses.

6. How do these solutions contribute to sustainability?

By analysing packaging efficiency and waste, smart systems help companies shift toward more sustainable materials and reduce environmental impact.

Conclusion

In a world that demands speed, visibility, and sustainability, smart packaging solutions powered by AI-integrated ERP systems are not just a competitive advantage — they’re a necessity. From optimizing supply chain workflows to delivering a better customer experience, these solutions represent the future of intelligent logistics and packaging.

For businesses ready to embrace this change, the path forward is clear: automate what can be automated, learn from every package, and let intelligence drive every decision. Ready to take the first step? Contact Qodenext today.