Supply chains are no longer linear or local—they are complex, interconnected webs stretching across countries, industries, and continents. While this scale offers great potential for efficiency and growth, it also introduces a growing challenge: supply chain regulatory compliance.

In this blog, we’ll break down what regulatory compliance entails, why it matters more than ever, common challenges businesses face, and practical steps to simplify the process.

What Is Supply Chain Regulatory Compliance?

Supply chain regulatory compliance refers to the process of ensuring that all operations, suppliers, and products within a company’s supply chain adhere to relevant local, national, and international laws and standards. These may include:

Environmental regulations (e.g., waste disposal, carbon emissions)

- Labor laws and human rights standards

- Trade and customs compliance

- Product safety and labelling requirements

- Data protection and cybersecurity mandates

- Anti-bribery and anti-corruption laws

For instance, companies importing goods into the European Union must comply with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) legislation. Similarly, the U.S. Food Safety Modernization Act (FSMA) applies to any food-related products distributed in the U.S., regardless of where they were produced.

Why Is Regulatory Compliance Crucial?

1. Avoiding Legal Repercussions

Non-compliance can result in hefty fines, product recalls, import/export restrictions, or even bans. In extreme cases, such offences invite criminal charges.

2. Building Customer Trust

Consumers are more conscious about the ethical and environmental impact of the products they buy. Demonstrating supply chain transparency and responsibility builds brand loyalty.

3. Safeguarding Brand Reputation

News travels fast. A single compliance failure—even if caused by a third-tier supplier—can severely damage a brand’s image.

4. Boosting Operational Efficiency

Streamlining compliance procedures often reveals inefficiencies, helps standardize processes, and ultimately improves supply chain performance.

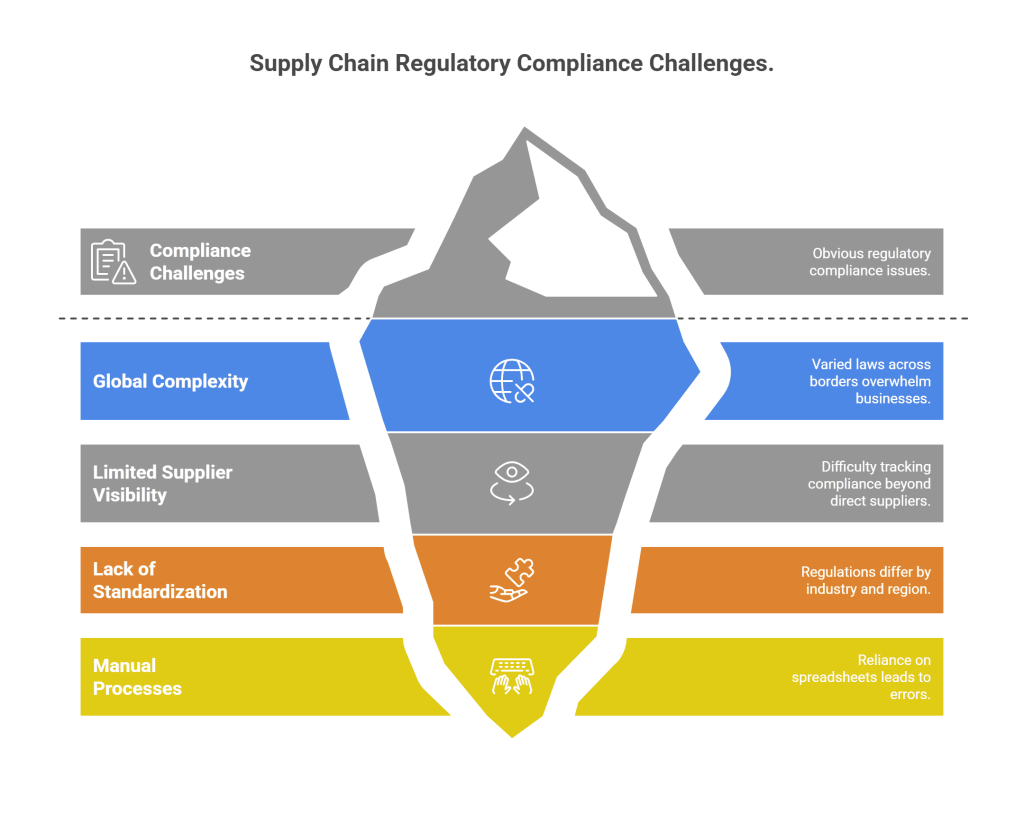

Challenges in Maintaining Supply Chain Regulatory Compliance

1. Global Complexity

Companies working across borders face varied and constantly changing laws. Managing compliance in diverse jurisdictions can be overwhelming, especially for businesses lacking in-house legal expertise.

2. Limited Supplier Visibility

Many organizations struggle to track compliance beyond direct suppliers. Tier-2 and Tier-3 suppliers might operate in regions with lax enforcement or different standards.

3. Lack of Standardization

There’s no universal compliance format. Regulations differ by industry, region, and product type, making it hard to maintain a unified approach.

4. Manual Processes

Many businesses still rely on spreadsheets and email for compliance tracking. This approach is prone to human error and lacks scalability.

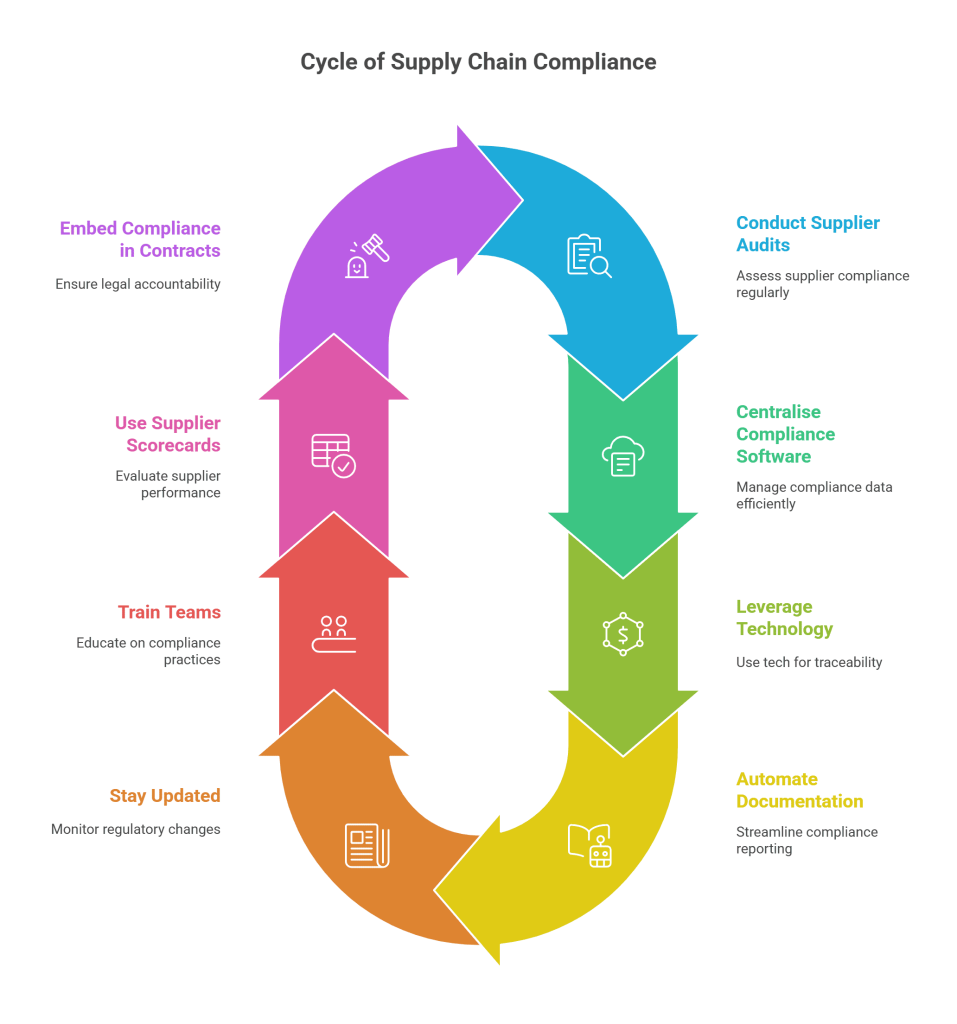

Strategies to Simplify Supply Chain Regulatory Compliance

1. Conduct Regular Supplier Audits

Begin by assessing your current supplier network. Regular audits ensure partners are following necessary regulations. Digital tools and third-party auditors can streamline this process and provide objective insights.

2. Establish a Centralized Regulatory Compliance Software

A single source of truth—like a cloud-based compliance management platform—can make a significant difference. It centralizes documents, certifications, inspection reports, and communication, making it easier to track and demonstrate supply chain regulatory compliance.

3. Leverage Technology for Traceability

Blockchain, RFID, and AI-based analytics allow companies to trace the origin and journey of products with precision. This kind of end-to-end visibility is increasingly demanded for industrial regulatory compliance.

4. Automate Documentation and Reporting

Automation tools can help collect, validate, and report compliance data in real-time, minimizing human errors and cutting down on manual effort in traceability in manufacturing.

5. Stay Updated with Regulatory Changes

Subscribe to regulatory news alerts or partner with compliance consultants who monitor and interpret legislative changes that may affect your industry or regions of operation.

6. Train Internal Teams and Suppliers

Provide regular training to employees and key suppliers on regulatory updates and best practices to ensure compliance and optimal performance. An informed workforce is your first line of defense against compliance breaches.

7. Use Supplier Scorecards

Assign compliance metrics to suppliers. Regularly evaluate their performance against these metrics and incentivize improvement.

8. Embed Compliance into Procurement Contracts

Make adherence to supply chain regulatory compliance a non-negotiable clause in supplier contracts. This creates legal accountability and encourages proactive compliance management.

Case Study: Apparel Industry and Compliance Pressures

The global apparel industry provides a compelling example of how supply chain regulatory compliance can be both a challenge and a competitive advantage. Following public outcry over sweatshops and unsafe working conditions, many major brands implemented stricter compliance audits, sustainability certifications, and public transparency reports.

Brands like Patagonia and Levi’s now publicize their supplier lists, worker policies, and audit scores, demonstrating a proactive approach. This not only helped improve working conditions across their supply chains but also strengthened customer loyalty and compliance regulatory processes.

The Role of Digital Supply Chain Platforms

Modern digital supply chain platforms now come equipped with compliance modules that monitor, alert, and manage regulatory obligations. These platforms integrate with ERPs and CRMs, providing real-time updates, audit trails, and certification management.

Companies using such platforms are able to:

- Automate risk assessments

- Get real-time alerts on expiring certificates

- Track supplier ESG (Environmental, Social, Governance) scores

- Generate audit-ready compliance reports

Investing in such systems pays long-term dividends by significantly reducing the effort and risk associated with managing supply chain regulatory compliance manually.

FAQs – Supply Chain Regulatory Compliance

1. What are the major regulations that affect supply chain operations?

Major regulations include REACH, RoHS, FSMA, GDPR, Dodd-Frank Act (conflict minerals), and CTPAT, depending on the industry and region.

2. How do I know if my suppliers are compliant?

Conduct regular audits, request certifications, and use supplier scorecards to track and evaluate performance.

3. Is compliance only necessary for direct suppliers?

No. Modern regulations often hold companies responsible for their entire supply chain, including sub-suppliers.

4. What tools help with supply chain regulatory compliance?

Tools include compliance management platforms, ERP systems with compliance modules, blockchain for traceability, and automation software for reporting.

5. How often should compliance audits be conducted?

It depends on the risk level and industry, but annually or biannually is a common standard for most companies.

6. What is the role of ESG in supply chain compliance?

ESG standards are increasingly embedded in compliance frameworks. Many investors and regulators now expect businesses to report environmental and social performance as part of their overall compliance efforts.

Conclusion

Supply chain regulatory compliance is no longer just a legal requirement—it’s a strategic necessity. As scrutiny from regulators, stakeholders, and consumers increases, businesses must rethink how they approach compliance. The good news? With the right mindset, tools, and processes, compliance can be simplified and even turned into a competitive advantage.

By embracing automation, fostering transparency, and staying agile in the face of evolving regulations, companies can ensure smoother operations, stronger partnerships, and a more trusted brand. For customised assistance in supply chain automation, contact Qodenext today.