At the core of maintaining a good supplier and customer relationship lies the effectiveness of the supply chain. It is like a collaborative affiliation. At the core of these supply chain relationships or affiliations lies inventory management.

The role of inventory in supply chain management is more than just keeping track of goods. It balances the demand with the supply. It allows the companies to create an important equilibrium of fulfilling the demands of customers. To understand its role in depth, let’s take a deep dive and answer what inventory is in supply chain management.

Understanding the Importance of Inventory Management

Inventory management at any organisation is all about identifying items or inventories and making a list. People in charge need to measure the quantities of each and stock them up. They should do so in a manner that such goods are easily accessible when one needs them.

Inventory management ensures tracking and management of inventory right from purchasing to the selling of goods. The role of inventory in supply chain management is to ensure that there is enough stock of goods to meet the customer orders. It allows them to identify any kind or order shortage and meet that.

Inventory management not only helps in overseeing a company’s stock but also plays a crucial role in averting stock shortages, which can negatively impact the company’s sales and revenue. There are inventory types in supply chain management and each have their role. Let’s see them in detail.

5 Types of Inventory Management Systems

1. Manual Inventory Management Systems

Before technology came to our rescue, people had to do all accounting activities manually. It was the same for inventory as well. To track inventory manually, companies have to manually count the items which leaves room for errors. However, with time businesses have shifted to automation.

With that in mind, let’s move on to the second type of inventory in supply chain management. It is a bridge between the manual and the perpetual system. Let’s see more about it in detail.

2. Periodic Inventory Management Systems

Wondering what is the role of inventory in supply chain management, especially the periodic systems? This method of tracking, gives employees more room to adopt both methods as per their convenience.

So, when a company uses a periodic management system, they will manually count their goods. This count could be periodically- weekly, monthly, or bi-monthly, depending on your business. This system is perfect for businesses with lower inventory levels.

While both periodic and manual systems have certain benefits, what if companies could find a solution that combines “the best of both worlds”? That is exactly what perpetual inventory does in the role of inventory in supply chain management.

3. Perpetual Inventory Management Systems

The perpetual inventory system is a real-time digital method for tracking stock levels and costs, aiding businesses in efficient inventory management. It helps identify slow-moving stock and optimises reorder levels for timely decision-making and loss prevention.

4. Just in Time (JIT)

JIT manufacturing produces goods only to meet immediate demand, minimising waste and enhancing efficiency. This role of inventory in supply chain management reduces the use of excess raw materials and finished goods. It suits businesses with fluctuating demand but carries risks in sudden demand changes.

5. Materials Requirement Planning (MRP)

MRP relies on sales forecasts to determine production and raw material needs. In the role of inventory in supply chain management, accurate forecasting is vital, making it suitable for businesses with predictable demand patterns. Industries with fluctuating demand, like steel, may find MRP impractical due to forecast challenges.

With so many types of inventories in supply chain management, what are their benefits to the system? So, let;s see what role inventory plays in supply chain management.

| System | How It Works | Best For | Limitations | Role in Supply Chain |

|---|---|---|---|---|

| Manual Inventory Management | Physical counting of items, records maintained manually. | Small businesses with low stock volumes. | High risk of errors, time-consuming. | Provides the demand of customers but lacks accuracy in inventory management in supply chain management. |

| Periodic Inventory Management | Stock counted at fixed intervals (weekly, monthly, etc.). | Businesses with lower inventory levels. | Data not real-time, prone to inaccuracies between counts. | Balances simplicity with cost control but delays decision-making. |

| Perpetual Inventory Management | Real-time tracking using software/ERP systems. | Medium to large enterprises. | Requires investment in technology. | Enables efficient inventory management in supply chain management with accurate visibility. |

| Just-in-Time (JIT) | Stock purchased/produced only to meet immediate demand. | Businesses with stable, predictable supply chains. | Risky with demand fluctuations or supply delays. | Minimizes waste, supports lean operations, but fragile to disruptions. |

| Materials Requirement Planning (MRP) | Uses forecasts to plan raw material and production needs. | Manufacturing industries with predictable demand. | Relies heavily on forecast accuracy. | Helps ensure that inventory provides the demand of production schedules. |

Role of Inventory in Supply Chain Management

Proper management of inventory is the backbone of successful business management. Managing goods from its raw materials state to “fully-formed products” is an imperative rule in supply chains.

This is where the role of inventory in supply chain management becomes more apparent as it oversees the flow of goods from production to consumption. This spans various stages-procurement, storage, tracking inventory levels, distribution, replenishing stocks and minimising costs.

Inventory management means looking after stuff in a smart way. This includes buying, keeping, and tracking things, making sure you have enough, but not too much. In India, how people handle their stuff has changed a lot because of technology, how people shop, and how the market works.

In simple terms, the role of inventory in supply chain management is to bridge the gap between production and demand. Inventory provides the demand of end consumers by ensuring that products are available at the right time, in the right quantity, and at the right place. Without efficient inventory management in supply chain management, companies face risks of overstocking, shortages, and inefficiencies.

The Importance of Efficient Inventory Management

The role of inventory in supply chain management encompasses its ability to ensure smooth business operations. When this management helps to maintain optimum inventory levels, companies are able to avoid stockouts or lost sales or dissatisfied customers.

Thus, as you can see, inventory plays a balancing act between having enough inventory to meet customer demands while minimising excess stock that ties up capital and incurs holding costs.

Read more about inventory accuracy here- How to Improve Inventory Accuracy for Maximum Efficiency?

For instance, having an overstocked inventory could result in wasted capital that the company could have used elsewhere, while having too little means missed business opportunities. To further improve supply chain management, there are a few benefits of inventory that every business must rein in-let’s see what they are.

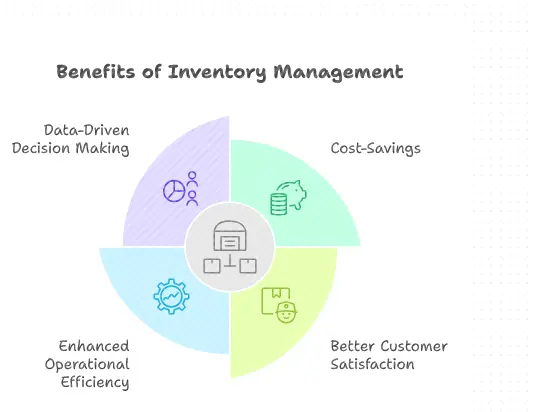

4 Advantages of Effective Inventory Management

1. Cost-Savings

An important role of inventory in supply chain management is to reduce the costs of inventory. Holding up stocks results in driving up prices when in reality it might have a use somewhere else. Similarly, insufficient inventory leads to production delays. Therefore, it is crucial to find the right balance for cost optimisation.

2. Better Customer Satisfaction

Delivering orders on time is important for happy customers. Keeping track of inventory helps make sure products are ready when customers want them, making the wait shorter and avoiding running out of stock.

3. Enhanced Operational Efficiency

When businesses keep a close eye on how much stuff they have and how much people want, they can make their stuff and buy more stuff in a smart way. This makes things work better, stops waste, and makes everything run smoother.

4. Data-Driven Decision Making

Apart from all these, the role of inventory in supply chain management is also to generate valuable data that companies can use in forecasting. They can use it for demand planning and supply chain optimisation. With accurate insights, companies can make informed decisions that align with market trends and customer preferences.

What kind of tool and techniques of inventory management helps the businesses to streamline their supply chain to meet customer demands? Find out below.

Role of Technology in Inventory Management

• Inventory Management Software and Tools

Boost your supply chain by adding a cloud-based system. It only helps to manage inventory but also works with accounting software. Such tools are easy-to-use and save time by automating tasks.

The role of inventory in supply chain management also prevents errors and cuts wastes, and reduces expenses. Plus, another thing about it is that you can access all information anywhere, even on your phone.

• RFID and IoT in Inventory Tracking

Utilise RFID and IoT for advanced inventory tracking. RFID tags and IoT sensors provide real-time data on inventory location, condition, and usage, enhancing accuracy and efficiency while enabling seamless monitoring and management.

Conclusion

In conclusion, the role of inventory in supply chain management is critical for balancing supply and demand. When businesses adopt effective inventory management in supply chain management, they ensure that inventory meets the demand of customers without overstocking or shortages. With technology-driven forecasting and real-time visibility, organizations can transform inventory into a strategic advantage.

Inventory management is like an invisible thread that ties together various entities of the supply chain management. In the last few years, inventory management has evolved along with business modules.

You can also say that this role of inventory in supply chain management is ever-evolving. Businesses must adopt streamlined supply chain strategies with the help of Qodenext to improve inventory management practices. Embracing these practices not only directly benefits businesses but also bolsters the health and resilience of the global supply chain ecosystem.

FAQs: Optimising Supply Chain Efficiency: Role of Inventory in Supply Chain Management

1. What role does inventory play in a supply chain?

Inventory management monitors flow of goods and materials in a supply chain. It includes tracking, storage and product distribution. It ensures that a business has adequate stocks when needed.

2. What makes a good inventory management system?

A flexible and well-rounded inventory management system must be able to forecast demand. Not only that it must also prevent product and production shortages. Additionally, it should also stop companies from having too many stocks and raw materials that might lead to shortages elsewhere. It also makes inventory analysis easy on any device.

3. Why is inventory management challenging?

There are some challenges due to the need for balancing costs, demand fluctuations, lead times, and storage, while ensuring products remain available and at optimal levels.

4. How can a supply chain deliver the most enterprise value?

Most enterprise value is possible by optimising efficiency. Also by reducing costs, enhancing customer satisfaction, and collaborating with suppliers and partners, supply chains deliver most enterprise value.

5. What supply chain management tools do businesses use to optimise their supply chains?

Businesses use various tools like Enterprise Resource Planning (ERP) software, Inventory Management Systems, Demand Forecasting Software, Transportation Management Systems, and Advanced Analytics to optimise supply chains by enhancing visibility, efficiency, and decision-making.

6. How does inventory management in supply chain management reduce costs?

Efficient inventory management in supply chain management lowers costs by minimizing excess stock, reducing storage expenses, and preventing wastage due to obsolescence. It also ensures the right products are available at the right time, avoiding costly emergency procurement.

7. What are the 5 types of inventory management systems, and which is best?

The five types of inventory management systems are Manual, Periodic, Perpetual, Just-in-Time (JIT), and Materials Requirement Planning (MRP). The best system depends on the size of the business, industry requirements, and demand patterns. For example, perpetual systems work best for large enterprises, while JIT suits lean manufacturing.

8. How does inventory provide the demand of customers in supply chains?

Inventory provides the demand of customers by acting as a buffer between supply and demand fluctuations. By holding adequate stock, businesses can quickly respond to customer needs, avoid stockouts, and maintain service levels even during disruptions.

9. What technologies are used in modern inventory management?

Technologies like RFID tags, barcode scanning, warehouse management systems (WMS), and AI-driven forecasting tools are widely used in inventory management. These technologies improve visibility, reduce errors, and optimize stock levels across the supply chain.

10. What industries benefit most from effective inventory management in supply chain management?

Industries such as retail, e-commerce, pharmaceuticals, automotive, and manufacturing benefit significantly. Effective inventory management in supply chain management ensures timely deliveries, compliance with regulations, and smooth production, directly improving profitability and customer satisfaction.