RFID technology is revolutionizing warehouse inventory management by offering smarter, faster, and more accurate tracking solutions. Radio Frequency Identification (RFID) uses tags and readers to automate inventory processes, reduce errors, and provide real-time visibility into stock movement.

As warehouses face growing demands for efficiency and accuracy, RFID warehouse management is becoming an indispensable tool for businesses aiming to streamline operations and cut costs. However, like any technology, RFID comes with its advantages and challenges.

In a better attempt to comprehend the effects of RFID, we can examine the application of RFID in practical warehouse settings by businesses.

Real-World Results of RFID in Warehouse Inventory Management Systems

Deloitte’s 2024 Global Supply Chain Report has indicated that RFID adopters in warehouse operations have realized:

- 25-40% faster inventory counting cycles

- As much as an 80% reduction of inventory errors

- 20-30% better labor productivity

For instance, Zara incorporates RFID in its stores and warehouses and raids the inventory time from days to hours while still achieving 98 percent stock accuracy. Amazon and Decathlon are also making use of RFID, with both having achieved near real-time visibility of stock movement to facilitate faster restocking and increased customer satisfaction.

Without a doubt, these examples in real life demonstrate that RFID warehouse management is not merely abstract theory – it delivers tangible ROI on a daily basis.

Before implementing RFID in your warehouse, it’s important to understand both the benefits and limitations to make an informed decision that aligns with your business goals.

Let’s see the impact of RFID in supply chain management- good and bad.

Pros of RFID Warehouse Management

Industries have been using RFID tags in their operations for decades now. These tags have simplified many processes allowing companies to save time and money. So, if you’re looking to optimise the efficiency of your warehouse inventory operations, consider RFID. here’s how it helps.

1. No More Manual Data Processes

Manual work takes time and money. In today’s fast-paced world, no business can afford to put in so much time to do work manually. The solution? RFID technology. It can automate many tasks.

RFID tech can help you locate any items inside the warehouse. What’s more – you can track the item even after it leaves the warehouse until it reaches its destination. RFID readers can scan the tags of the items at the entrance and exit of warehouses.

With real-time tracking of inventory, it can update the systems about the items that have moved out and the ones that are coming in.

2. Increased Accuracy

With RFID tags, there’s less risk of human error. When you enter information manually, usually there’s a chance of making errors. But by automating the process you can reduce that possibility. This accuracy boosts productivity and streamlines efficiency in your warehouse.

Increased efficiency due to using RFID warehouse management and logistics, can also have an impact on profits. When there are more accurate operations in logistics, items move out in time. This allows the companies to sell their desired quantity at their time pace, making profits and curbing losses.

3. Enhanced Inventory Visibility

Leveraging RFID in inventory allows you to have accurate and real-time information on your stock levels. This helps you to avoid overstocking and understocking.

4. Reduced Labour

Automating tasks means you will not need as many employees. They enhance efficiency, decrease human error, and cut down the need for manual data entry, resulting in faster and more accurate production processes.

5. Improved Customer Satisfaction

As you increase the efficiency of your warehouse operations, you also make your customers happy. By streamlining operations with RFID warehouse management, increasing the pace of delivery and reducing errors, you can ensure your customers are happy!

6. No Line of Sight for RFID Tags

Perhaps the best reason, RFID tags remain a preference in the industries is because of their scanning capabilities. You do not need a worker to face the scanner at the tag to scan the items. You can scan multiple tags at once. That’s why many industries from retail to healthcare to manufacturing are using RFID tags.

7. Stores More Data Than Barcodes

Barcodes are essentially identifiers linked to a database where the item’s details are stored. In contrast, RFID tags store extensive data directly on the tag, encompassing various information types. This data can be accessed and utilised without needing a connection to an external database.

Not just all of these, with RFID inventory management you can optimise your floor layout.

8. Optimise Your Floor Layout

RFID tags offer you real-time data. You scan the barcodes and get all the information about the items. This means that at all times, you have a clear picture of what is happening on the warehouse floor.

You can know which items personnel are picking up and which items are being restocked. Using this data, warehouses can reconfigure inventory to optimise operations. Not just that they can make RFID warehouse management frequent and swift.

However, like all processes, there are some limitations to using RFID for asset tracking and inventory management. The roadblocks usually come in when certain industries have not yet familiarised themselves with the latest technology they need for RFID tracking.

Let’s see why some industries would lag.

Cons of RFID Warehouse Management

Even with all the latest tech and ever-evolving tools, not all can fully capture the advantages of RFID. RFID does come with some drawbacks, but that only happens when companies or individuals fail to grasp its concept. They are:

1. Lack of Understanding

Many individuals still fail to completely understand the RFID technology which can lead to errors and hesitancy from customers and stakeholders.

2. Privacy Concerns

With an increase in the use of technology, some people may be worried about non-consensual data collection or being tracked.

3. Interference

Radio waves used in RFID systems can be disrupted by materials like metal and water in your warehouse, leading to reading errors.

4. RFID Tags are Expensive

These tags are usually on the pricey side, individual tags cost more and parts are not replaceable. This means if a part of the tag becomes faulty, you have to replace the whole product.

RFID warehouse management has two types- active tags and passive tags. While passive RFID tags are more affordable, the cost can add up for bulk applications. Active tags with batteries are significantly more expensive, impacting large-scale deployments.

5. Interference Problems

While it’s true that you don’t need a line of sight to “read” the tags, there still exists a problem. You can’t just read these tags from anywhere at any angle or in all conditions. If there are physical barriers between the reader and the tag then scanning it becomes a challenge,

6. No Standardisation

Inconsistent standards for RFID tags and data can cause headaches for international supply chains. Different regions may require incompatible systems, raising costs and complexity.

Knowing all the pros and cons of RFID warehouse management, you can adopt the best practices. This ensures you can harness the full “power” of RFID tags.

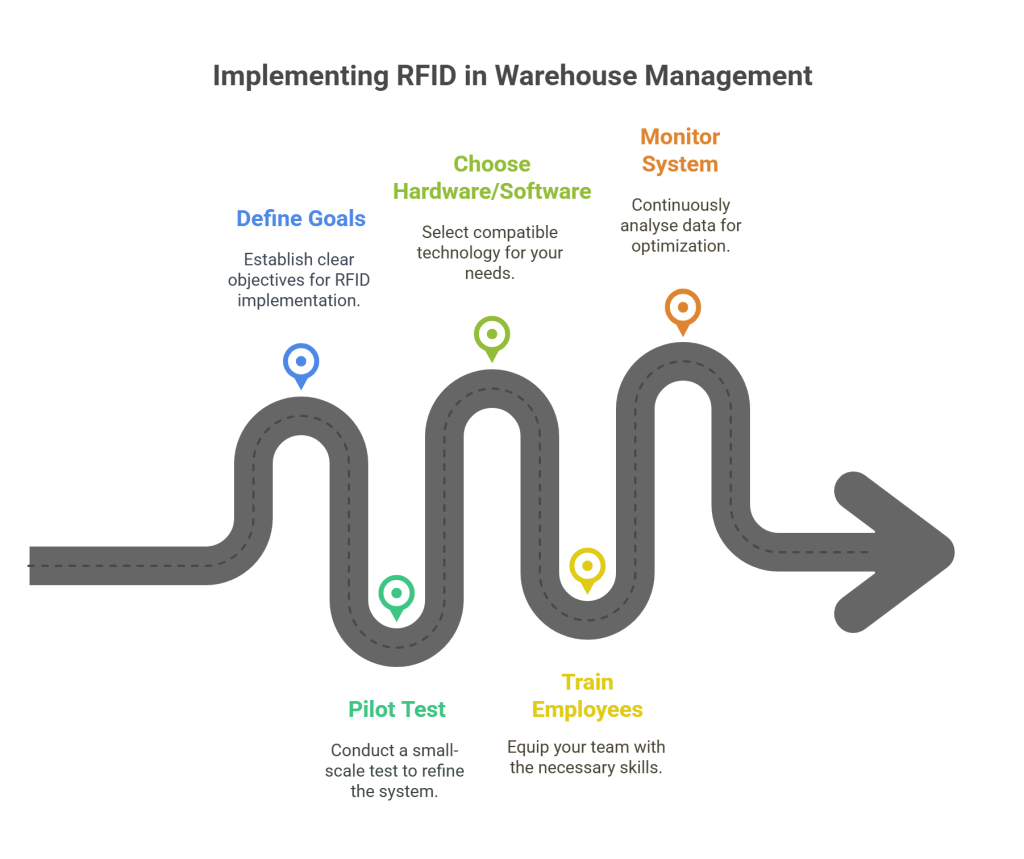

RFID in Warehouse Management Best Practices

1. Define Your Clear Goals:

Finalise what you want to achieve with RFID technology in your warehouse. Align them with your business objective.

2. Do a Pilot Test:

Don’t jump in! Run a small-scale RFID pilot to iron out wrinkles and confirm it delivers the benefits you expect.

3. Choose the Right Hardware and Software:

Choosing software and hardware that is compatible with your existing systems and meets your business needs is crucial.

4. Train Employees:

Empower your team with RFID training to seamlessly integrate it into their workflows.

5. Monitor:

Regularly monitor and analyze the system’s data to identify optimization opportunities and keep your inventory management sharp.

All of these help in driving efficiency and cost savings through data-driven RFID warehouse management.

Conclusion

RFID technology significantly improves warehouse inventory management by enhancing accuracy, visibility, and operational efficiency. While the initial investment and potential interference issues may seem daunting, the long-term gains in productivity and customer satisfaction make RFID a smart choice for modern warehouses.

By understanding the pros and cons, and following best practices like pilot testing and employee training, businesses can fully harness the power of RFID to optimize their supply chain operations and drive profitability.

For companies seeking to upgrade their warehouse management, RFID offers a future-ready solution that can transform how inventory is tracked and controlled.

Qodenext provides modern supply chain solutions, including RFID technology. Learn how we can streamline your operations and boost profits.

FAQs: Pros and Cons of RFID in Warehouse Inventory Management

1. What determines the cost of RFID tags?

The price of RFID tags depends on several factors, including the industry of use and whether the tag is designed for single-use or long-term applications. Factors influencing cost include:

Type of RFID chip used, Memory capacity, Durability and resistance to heat, chemicals, or freezing, Tamper-evidence features. Generally, active RFID tags (which have internal batteries) are more expensive than passive tags, which are more common in logistics and retail.

2. How much information can RFID tags store?

Storage capacity varies by tag type:

- Basic RFID tags may only store a unique identification number

- Industrial-grade tags can store up to 2KB of data, including item details

- High-memory tags used in aviation can store 4KB–8KB

- Specialized military-grade RFID tags may store as much as 128KB

3. What are the three types of RFID tags?

RFID tags are categorized by frequency: Low Frequency (LF): Ideal for short-range, interference-resistant uses, High Frequency (HF): Common in smart cards and ticketing, Ultra-High Frequency (UHF): Offers the longest read range, widely used in logistics and supply chain

4. What are the main benefits of using RFID in warehouse inventory management?

RFID enhances warehousing by:

Improving inventory accuracy, Enabling real-time tracking, Reducing manual labor and human error, Boosting overall efficiency and throughput

5. How does RFID technology work in a warehouse environment?

RFID tags are affixed to items or containers. These tags transmit data via radio waves to RFID readers, enabling automatic identification and tracking without needing direct line-of-sight, unlike barcodes.

6. What are the differences between active and passive RFID tags?

- Passive tags have no power source; they rely on the reader’s signal and are cost-effective but have shorter read ranges.

- Active tags contain internal batteries, offer longer read distances, can store more data, and are ideal for high-value assets or real-time tracking.

7. Can RFID technology face challenges in warehouses?

Yes. Common challenges include:

- Interference from metals, liquids, or physical obstructions

- Signal inconsistency due to warehouse layout

- Compatibility issues across global supply chains due to non-standardized protocols

8. Is RFID technology expensive to implement in warehouses?

While initial setup costs can be high—especially with active RFID systems—the long-term benefits such as error reduction, labor savings, and faster fulfillment typically offset the investment.

9. Does RFID technology improve customer satisfaction?

Yes. By enhancing warehouse efficiency, reducing order errors, and speeding up order processing, RFID enables faster, more accurate deliveries, leading to improved customer trust and satisfaction.