When you talk about the automobile industry, these products need heavy transportation charges. You can’t afford to commit any mismanagement in the supply chain. Each product has a huge manufacturing cost and a worth noticing profit margin. In that case, you need every piece of information from the completion of the final product to delivery.

Data tracking and processing is upgraded now, and RFID technology can help you to cross ahead of your competitors. Take a close look if you are interested to know the power of RFID vehicle tracking systems to increase the operational efficiency of the Supply Chain.

What Is an RFID Vehicle Tracking System?

Radio Frequency Identification (RFID) is a wireless identification technology that is powered by radiofrequency waves. In this system, each vehicle is equipped with a unique RFID tag. As soon as a vehicle equipped with RFID tags passes by one of these reader hubs, all the data about the vehicle is sent to the central databases for tracking and analysis.

This powerful technology is beneficial for the vehicle and logistics industry for various purposes, including fleet management, vehicle access control, and inventory tracking. They are becoming increasingly popular as a way to increase safety, efficiency, and productivity in the transportation industry.

How Does RFID Vehicle Tracking System Work?

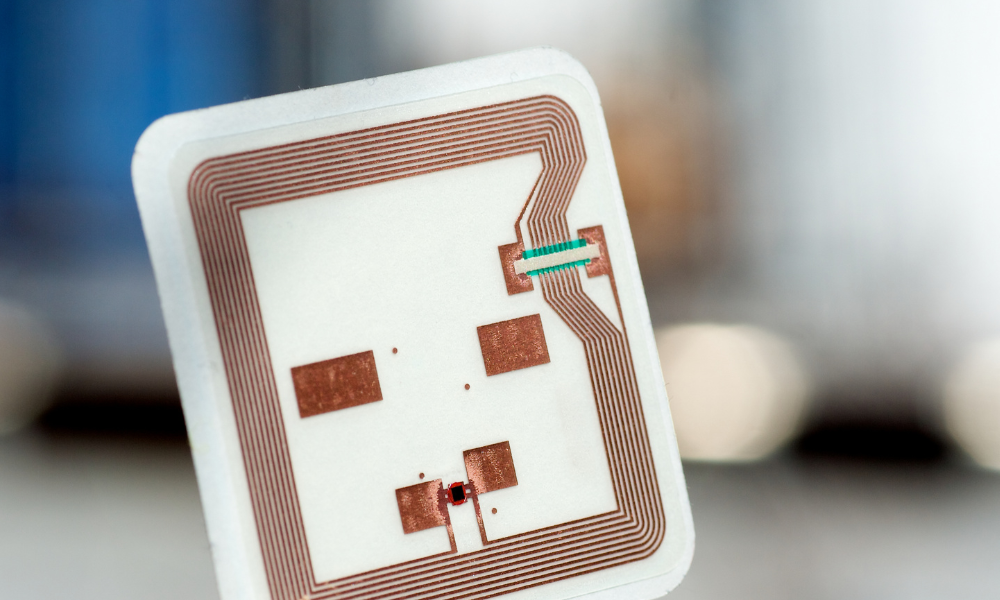

The working of the RFID vehicle tracking system involves two key components: RFID Tags and RFID Reader.

- RFID Tags: It is an electronic tag or a microchip with an antenna, which is supposed to be installed in a vehicle for transmitting data to the reader. The most suitable spot for placing these tags are windshield or bumper of the vehicle. Tags are the core tracking elements of the RFID tracking process.

- RFID Reader: These RFID readers receive and read the data transmitted by RFID tags. To be specific, these readers emit radio waves and receive signals from the RFID tags. The main flow of information and tracking required the proper installation and functioning of both RFID Tags and Reader.

RFID has a certain range and a scope of tracking data. Whenever a vehicle with RFID tags enters the tracking zone, the reader emits radio waves and powers the microchip present in the tag. The tags then immediately send out a back signal, including information about their exclusive ID.

All the data received from RFID tags are then processed. This process can reveal the time, location, entry, exit, and a lot of other information associated with the vehicle. The information associated with the owner can also be gathered if the vehicle is sold and registered.

The data is later analyzed and stored in the central databases. All the crucial information can be used to track and monitor the movement of vehicles. It can also monitor traffic flow and improve the efficiency of tracking.

Advantages of RFID Vehicle Tracking System in Supply Chain Management

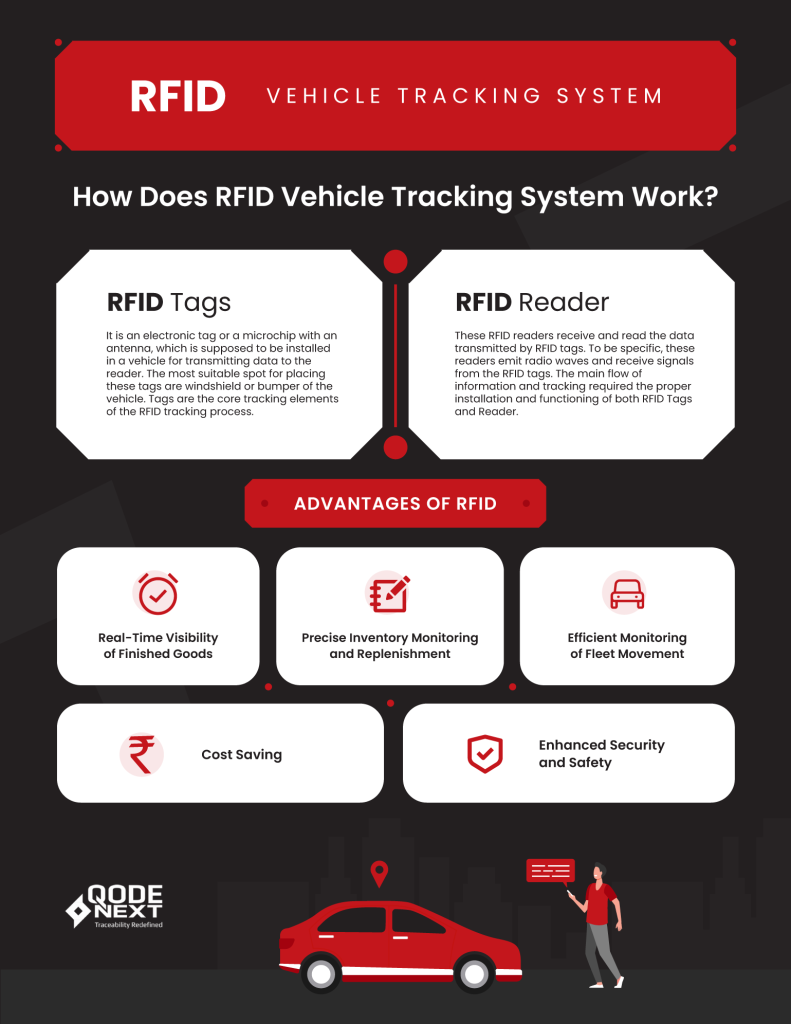

RFID vehicle tracking systems are an invaluable tool for managing supply chains. By providing real-time visibility of shipments, RFID can help to improve efficiency, reduce costs, and ensure quality control throughout the entire process.

It allows companies to monitor their fleet’s location in real-time and keep track of every aspect of a shipment – from start to finish. All these benefits can help companies improve their overall supply chain management performance. Let’s explore the depths of the topic at hand.

1. Precise Inventory Monitoring and Replenishment

The RFID vehicle tracking system is run through automation. It is machine-enabled, so the data synthesis and analysis is very precise. Thus, it allows you to have real-time data on your inventory. Besides, this system also generates automatic alerts when inventory levels reach a certain threshold, ensuring timely replenishment of stock.

2. Real-time Visibility of Finished Goods

The RFID vehicle tracking system helps you stay updated with the real-time status of vehicles. Thus, it streamlines your supply chain with improved visibility and control. With this innovative solution, businesses can easily spot delays or obstacles within their supply chain and make necessary adjustments to ensure timely delivery.

3. Efficient Monitoring of Fleet Movement

Fleet movement can be tracked more efficiently with the help of multiple tracking information. You can track every vehicle’s location, speed, and other important details to help optimize routes and schedules, cut down on fuel usage, and boost efficiency across the board.

4. Cost Saving

Using RFID tracking systems, you can optimize delivery paths and reduce fuel usage, resulting in considerable cost savings. Thus, it is a cost-effective option to opt for vehicle tracking and supply chain management.

5. Enhanced Security and Safety

With an RFID vehicle tracking system, you can track your vehicles anywhere, anytime. Thus, the chances of your assets getting lost are minimized. Moreover, you can also track your lost assets. Thus, it can provide security against unauthorized access to your assets.

RFID Vehicle Tracking System vs GPS Vehicle Tracking System

RFID which stands for Radio Frequency Identification, has tags and a transponder to track vehicles. But GPS (Global Positioning System) uses satellite signs to spot the exact location. GPS is less reliable for a confined area, as the satellite signs may be weaker. RFID can work perfectly even in indoor spots as they use microchips and antennas for communication.

When it comes to tracking vehicles, GPS is great for on-the-go, but RFID takes things to the next level by recording arrivals and departures at depots. RFID can provide pin-point accuracy of location, but it covers a small range. If you check GPS, it covers a greater range.

The best part of RFID systems is that they offer a more affordable option compared to GPS. These systems are perfect for monitoring vehicles within smaller areas, like warehouses and factories.

Hey! Are you looking for a reliable vehicle tracking solution? Don’t forget to check out this comprehensive truck management solution by QodeNEXT, TITO . Using RFID, BLE, and IoT technologies, TITO provides enhanced visibility and control of truck movements, improving the functionality and reducing operational costs.

With TITO, you can expect improved turnaround time by up to 30% and many more benefits. What more are you waiting for? Check out TITO by QodeNEXT now!

FAQ : RFID Container Tracking System

What is an RFID vehicle tracking system?

An RFID vehicle tracking system is a system where vehicles are monitored or tracked by using RFID tags. The system includes RFID tags and readers to track the location of vehicles and transmit data.

How do RFID vehicle tracking systems improve safety and security?

RFID vehicle tracking systems offer – real-time tracking to minimize the risk of theft or unauthorized access. Moreover, these vehicle tracking systems also come with other advanced security features, such as geofencing and anti-theft prevention, which keep your vehicle and assets safe and secure.

Can RFID and GPS vehicle tracking be used together?

Yes, you can combine RFID and GPS vehicle tracking systems for complete coverage.

Which is more affordable, RFID or GPS vehicle tracking?

RFID is typically less expensive than GPS, which makes it a suitable choice for tracking vehicles in constrained spaces like factories and warehouses.

What makes an RFID vehicle tracking system better than GPS?

GPS systems may become less reliable when used in areas with limited space or enclosed environments due to weaker satellite signals. On the other hand, RFID technology utilizes microchips and antennas to communicate and can work seamlessly, even in indoor locations.

Conclusion

RFID vehicle tracking systems provide businesses with a reliable and cost-efficient solution to improve their supply chain management performance. It offers precise inventory monitoring and replenishment real-time visibility of finished goods. It efficiently monitored fleet movement and enhanced security and safety. Moreover, the potential of RFID technology in supply chain management is immense, and its possibilities are endless.

With further advancements in technologies such as sensors, cloud computing, artificial intelligence, blockchain, and the Internet of Things (IoT) it will continue to revolutionize supply chain management, enabling businesses to streamline their operations.

Contact us at Qodenext today to take your operations to the next level.