The world of manufacturing is constantly evolving at a rapid pace and functions fast in real time. So, efficiency is very important for it. Most of the elements of the manufacturing industry like supply chains are good examples of where the products and items travel through various checkpoints. So, there needs to be a tracking system.

Enter RFID technology.

Radio Frequency Identification (RFID) technology is a wireless system of tags and readers. It uses electromagnetic fields to identify and track tags of any objects. It’s useful for improved inventory management, enhanced asset tracking, and increased operational efficiency.

As automation takes over, it guarantees accuracy in real time. That is the power of RFID in manufacturing industry. It not only streamlines operations; it drives productivity and quality to new heights.

RFID tracking in manufacturing processes can streamline production and enhance quality control. You can now bid your goodbyes to manual tracking and confusing inventory management.

So, let’s explore how RFID is reshaping the manufacturing landscape and propelling businesses towards greater success.

Key Components of RFID in Manufacturing Industry

The entire RFID technology is dependent on its components. Each of them performs a specific function to streamline the supply chain processes. Let’s see what they are:

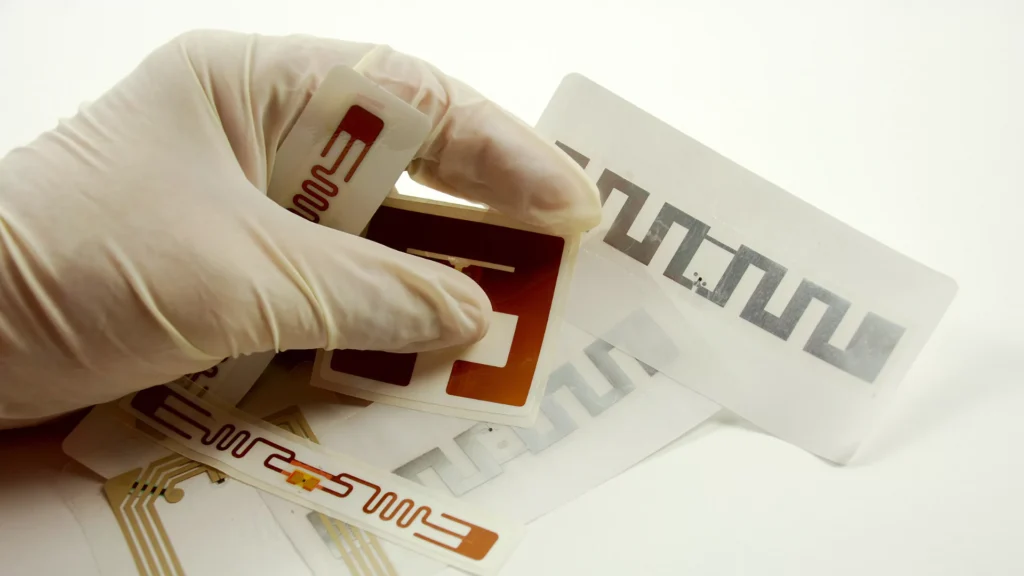

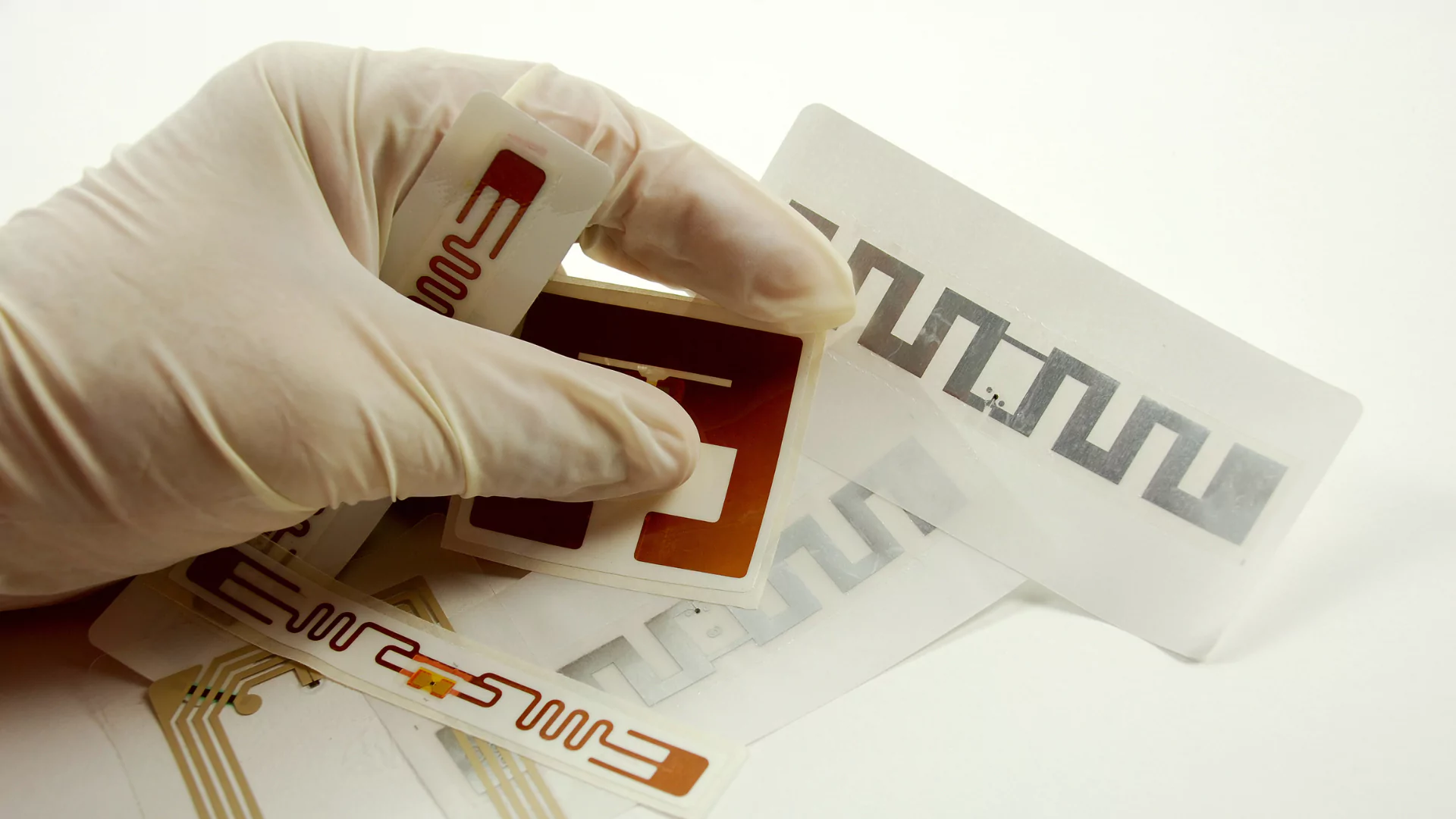

1. RFID Tags

These tags are like smart labels. They can store a range of information from serial numbers to a short description to even pages of data. These devices can be either active or passive. The former comes with a battery which means it is always “on’. Whereas you can only power up the passive one upon scanning it.

To put RFID Tags into context, in a shipment, you can quickly scan all of the assets upon exit and entry at the other end, saving time and resources.

2. RFID Reader

Another name for this technology is Radio Frequency Identification Scanner or scanner for short. This network-connected device is portable or permanently attached to the goods or products. it uses radio waves to transport the signals that activate the tag.

Each tag of RFID in manufacturing industries has its unique identification. It is like a form of barcode that people can batch read and allow everything from inventory management to logistics to manufacturing to run more smoothly.

Lastly, we come to the database that stores all the information related to the goods in the supply chain.

3. RFID Database or System

Any RFID system uses radio waves to identify and track objects that have RFID tags. There is electronically stored information on these tags. The system consists of readers to capture data from tags and a database to store and manage this information. Through wireless communication, RFID enhances inventory management, access control, and logistics, providing real-time tracking and improved operational efficiency.

Learn more about the RFID tags from the best use cases for RFID in manufacturing industry.

How Does RFID in Manufacturing Work?

RFID tags have a myriad of uses. But how does it play out for the manufacturing industry? Let’s have a closer look.

1. Plant Security

RFID tags are useful when it comes to security in manufacturing as well. For instance, it can help people to regulate and control access. Companies can use them in place of passwords to identify staff.

If there is an error then you can track it back to the source and find out what or who was responsible for the problem.

2. Inventory Management

As you know by now, RFID tags help in inventory management. With it, you can have a glance at the stock in your inventory. But not just that. RFID tags also help companies to get a better grasp of their WIP or Work in Progress.

3. Quality Control

Leveraging RFID technology enables the maintenance of quality standards even in demanding environments. Specific tags can track alterations and detect any damages that may occur. Continuous data feedback to the system during manufacturing facilitates the identification of flaws or deviations.

4. Manufacturing Operations

Accessing real-time information on product execution empowers factories to enhance efficiency and minimise downtime. RFID tags enable precise determination, management, and customization of production steps for each project. This capability is particularly beneficial for companies handling numerous custom jobs, as it efficiently provides pertinent information to machinery or workers.

5. Equipment Optimisation

One of the ways that RFID works in manufacturing is how it can improve the efficiency of your equipment. Knowing when your equipment or machinery needs repair or servicing can greatly help to control this. This is where RFID tags come in as they collect data.

With the data from the RFID tags, companies can know about the machine’s health. This allows them to be always aware of the machinery’s status and schedule updates and servicing accordingly. It reduces or even eliminates downtime.

6. Logistics and Tracking

At the end of the manufacturing process, lies the transport and eventual use or sale of the items. In this case, RFID in manufacturing industry is still relevant as a useful technology. The tags can track the assets and provide additional information about the logistical side of the manufacturing process.

Surely, using these innovative tags might have some advantages. What is the benefit of RFID? Let’s find out.

Advantages of RFID in Manufacturing

These tags are important and in use across various industrial sectors here are some reasons why they are so sought-after:

1. Operational Benefits

Here is how RFID tags strategically help the supply chain management:

a. Inventory Counting

Regardless of which area of manufacturing you work in, doing stocking or inventory checks 9a tedious and quite a traditional process. To be honest, it can be a waste of time. So why not automate it?

Having a way to efficiently and automatically scan a whole room or section of the warehouse is easier. Using RFID in manufacturing industry takes less time and streamlines the process,

b. Supply Chain Visibility

When manufacturers have an increased level of visibility in the whole supply chain, it begets its advantages. It helps with resource management, reducing shipping errors and planning.

One of the major issues with supply chains is that huge portions remain a mystery. This can give rise to multiple issues. RFID in manufacturing industry processes helps alleviate those issues.

c. Asset Tracking

You can track everything- from a small manufacturing piece to a completed car. As long as the RFID tracker is there on or inside the asset, the companies can track and manage it with ease.

Knowing exactly how many of something (number of assets) you have allows you to manage reordering or shipments much more effectively and efficiently.

The benefits of RFID in manufacturing industry extend beyond its operational boundaries. Here are some more advantages.

2. General Benefits

Apart from strategy and business-related functions, there are also some comprehensive benefits of RFID uses:

a. Reduces Errors

Multiple errors can hinder visibility in the supply chain. A tracking system reduces the chances of errors thus making the supply chain more visible from start to finish. This allows management to identify patterns or highlight issues and pinpoint problem areas.

For example, eliminate shipping volume errors by knowing the exact amount of assets in transport.

b. Controlled Environment

RFID in manufacturing industry generates new information which creates a much more controlled environment and makes management much simpler. Now you can have access to data like instant inventory checks or if there is any production error. This also works wonders in the case of security.

c. New Layer of Security

Having a system that can streamline operations and double up as a form of security is the perfect example of “two birds, one stone.”

Regulate stricter control over your products and raw materials, you can limit internal and external threads aligned with tracking your assets to their destination.

Regardless of your position in the supply chain, you would need the help of Radio Frequency Identification. It has changed the game owing to its various uses. As time goes by RFID in manufacturing industry will also undergo evolution with logistics becoming more streamlined than ever before.

FAQs: How RFID in Manufacturing Industry Revolutionises Operations

How does RFID track assets?

RFID can track assets with the help of radio frequency signals. The tags emit these signals which RFID readers detect and record.

Is RFID new?

RFID technology has been around for decades. Advancements and applications continue to evolve, making it a continually relevant and improving technology.

How can RFID improve worker safety?

Of course, it can improve worker safety. The tags enable real-time tracking of personnel and monitor hazardous environments providing instant access to safety procedures and alerts.

Conclusion

The technology of RFID in manufacturing industry stands as a transformative force, revolutionising operations from inventory management to quality control. With its ability to streamline processes, enhance safety, and optimise equipment, RFID not only boosts efficiency but also propels businesses towards greater success. Head over to Qodenext to avail the latest supply chain innovations and solutions.