Traditional methods of tracking assets—manual logs, barcodes, or spreadsheets drain resources. Enter RFID asset tracking, a game-changing technology that enables businesses to automate asset visibility, reduce losses, and optimise logistics. Among the pioneers in this space, Qodenext has redefined the landscape with its advanced RFID solutions, delivering unprecedented speed, accuracy, and scalability.

Let’s delve into how Qodenext’s RFID technology is revolutionizing asset tracking across industries—from manufacturing and logistics to healthcare and retail.

What is RFID Asset Tracking?

RFID (Radio Frequency Identification) asset tracking is the process of using electromagnetic fields to identify and track tags attached to physical assets automatically. These tags contain electronically stored information that can be read remotely using RFID readers, without a line of sight, unlike traditional barcode scanning.

Each tag has a unique identifier, enabling accurate tracking of individual assets across facilities, warehouses, or even globally. With RFID asset tracking, companies gain real-time visibility of the movement, status, and condition of their assets, allowing for intelligent decision-making and proactive inventory management.

Why RFID in Asset Management?

While barcode systems and manual logs have been industry standards for decades, they are limited in scope, especially when scaled. RFID trumps these traditional systems in several ways:

- Non-line-of-sight scanning: Multiple tags can be read simultaneously even if they’re not visible to the scanner.

- Speed and efficiency: RFID can scan hundreds of assets within seconds.

- Real-time updates: Changes in asset status are instantly recorded and reflected in the backend system.

- Durability: RFID tags are more robust and resistant to wear and tear.

By switching to RFID tracking systems, businesses eliminate human error, reduce labour costs, and gain a significant boost in operational productivity.

How Qodenext is Changing the RFID Landscape

Qodenext is at the forefront of intelligent supply chain automation and is a trusted name for businesses looking to digitize their operations. With its holistic RFID ecosystem—including hardware, software, middleware, and consulting—it delivers turnkey solutions tailored to industry-specific requirements.

Here’s how Qodenext’s RFID tracking systems are driving real change:

1. Custom-Engineered RFID Hardware

It provides a wide range of rugged, high-performance RFID hardware such as handheld readers, fixed readers, and antenna systems that support UHF (Ultra High Frequency) RFID, suitable for long-range and high-volume applications. These are built to withstand harsh industrial environments, ensuring real-time asset tracking and consistent performance.

2. Smart Tags for Diverse Applications

It offers passive and active RFID tags that can be applied to everything from metallic machinery and medical equipment to pallets and returnable transport items (RTIs). Their tags are engineered for maximum read range, temperature resistance, and long lifecycle, making RFID asset tracking feasible in even the most challenging use cases.

3. AI-Integrated Traceability and Software

The true power of RFID lies in how data is interpreted. It automation intelligently processes the millions of tag reads, filters noise, and delivers actionable insights to the ERP or WMS. Their software dashboards provide granular visibility tracking of asset lifecycle, location history, usage frequency, and compliance, all in real time.

4. End-to-End Implementation

From RFID site surveys and infrastructure planning to tag commissioning, integration with existing IT systems, and staff training, It ensures end-to-end project success. This eliminates the risk of fragmented deployment or technology underutilization.

Industry Applications of RFID Asset Tracking

Qodenext’s RFID solutions are powering digital transformation across diverse sectors:

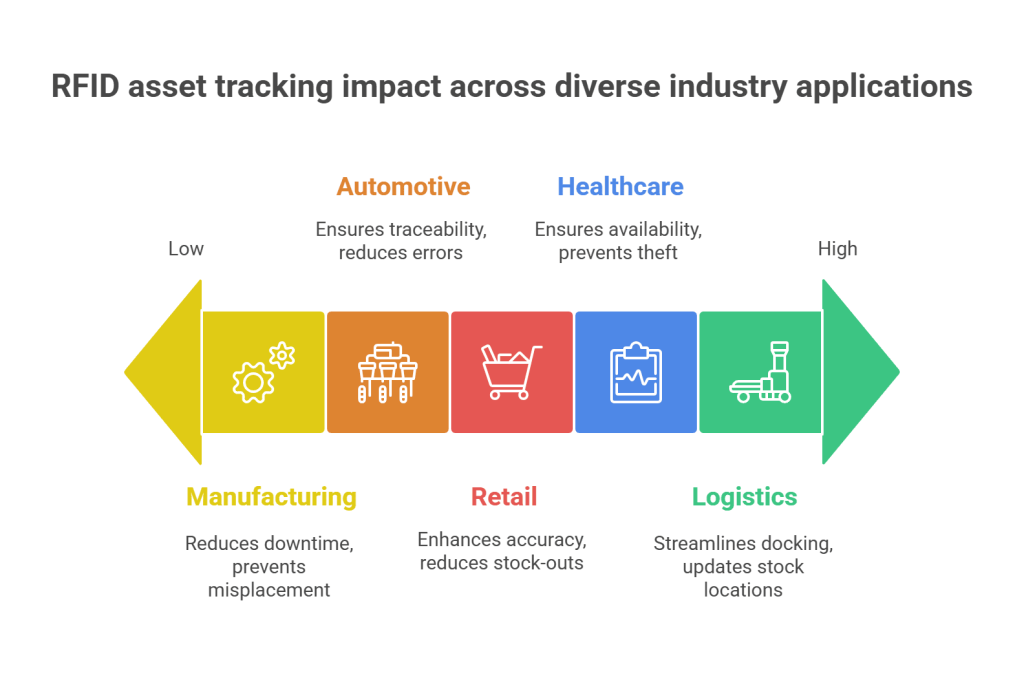

1. Manufacturing

Manufacturers use RFID asset tracking to monitor tools, dies, and machine components on the shop floor. Real-time insights reduce downtime, prevent asset misplacement, and support predictive maintenance.

2. Logistics & Warehousing

For logistics providers, RFID streamlines vehicle docking, yard management, and pallet tracking. Forklifts equipped with readers can automatically update WMS with stock locations without manual scans.

3. Healthcare

Hospitals and pharmaceutical companies track medical equipment, wheelchairs, IV pumps, and controlled substances using RFID. This ensures availability, prevents theft, and improves audit compliance.

4. Retail

In retail, RFID asset tracking enhances inventory accuracy, reduces stock-outs, and prevents shrinkage. It RFID tags enable fast stock audits and omnichannel inventory visibility.

5. Automotive

Auto manufacturers track components across assembly lines to ensure traceability and reduce errors. RFID also helps in tracking returnable packaging like crates and containers.

The ROI of Implementing Qodenext’s RFID Asset Tracking

Many companies hesitate to switch to RFID tags for asset tracking due to initial investment concerns. However, the ROI is clear and measurable:

- 95% reduction in inventory audit time

- Up to 40% drop in asset loss and theft

- Faster asset utilization and equipment turnaround

- Significant drop in manual labor costs

- Better regulatory compliance and audit readiness

Businesses using Qodenext’s RFID asset tracking report improved asset lifecycle management, streamlined workflows, and made faster decision-making.

Key Features of Qodenext’s RFID Solution

- Scalability: Suitable for single warehouses or multi-site enterprise deployments.

- Plug & Play Integration: Works with SAP, Oracle, Microsoft Dynamics, and custom ERPs.

- Geo-Fencing & Alerts: Get notified when an asset moves outside designated areas.

- Data Security: Role-based access, encrypted data transfer, and secure cloud hosting.

- Mobile Access: Monitor and manage assets remotely via mobile devices or tablets.

Each of these features ensures that RFID isn’t just an add-on, but a core enabler of smart operations.

Future-Proofing with RFID and IoT

The convergence of RFID with IoT and AI is shaping the future of asset intelligence. Qodenext is actively investing in building predictive capabilities using sensor-rich RFID tags that can also monitor temperature, humidity, shock, or tampering.

Imagine a scenario where your asset not only tells you where it is, but also what condition it’s in—and notifies you before something goes wrong. That’s the promise of next-gen RFID asset tracking, and Qodenext is building it today.

FAQs on RFID Asset Tracking

1. What types of assets can be tracked with RFID?

Almost any physical asset—equipment, tools, pallets, medical devices, vehicles, and more can be tagged and tracked using RFID.

2. How is RFID different from GPS tracking?

RFID is ideal for indoor tracking (e.g., warehouses, hospitals), while GPS works better for real-time outdoor tracking. RFID doesn’t rely on satellite signals and consumes less power.

3. Can RFID tracking work in harsh environments?

Yes. Qodenext provides industrial-grade RFID tags and readers that can withstand heat, moisture, chemicals, and impact.

4. How secure is the data collected through RFID?

Qodenext’s system uses encrypted data channels and secure authentication protocols. Role-based access ensures only authorised personnel can view asset data.

5. What’s the typical deployment time for an RFID system?

Deployment time varies based on the size of the operation. A pilot can go live in 4–6 weeks, while full-scale rollouts may take a few months, including integration and training.

6. Is RFID asset tracking suitable for small businesses?

Yes. Qodenext offers modular solutions that can scale up as your business grows. Even SMEs can benefit from the automation and visibility that RFID offers.

Conclusion

The future of asset tracking is intelligent, automated, and always connected. As businesses navigate complex supply chains, rising costs, and stringent compliance demands, solutions like RFID asset tracking are no longer optional—they’re essential.

By digitizing asset visibility and reducing operational blind spots, organizations can do more with less, ensuring efficiency, traceability, and growth.

If you’re ready to move beyond outdated tracking methods and take control of your assets in real time, Qodenext’s RFID tracking solution could be the catalyst for your next wave of operational excellence.