Retail inventory management is the secret formula of successful retailers. It includes all the items stored, packaged, and moved during regular operations. Physical stores and e-commerce sellers rely heavily on inventory planning and management to fulfil customer demands and distribution channels.

The rapidly growing eCommerce industry necessitates a detailed understanding of inventory processes amidst the chaos of planning, integration, control, and distribution, Let’s explore retail inventory operations and tackle the what, why, and how of the modern retail industry.

What is Retail Inventory Management?

Let’s suppose you opened a retail store in any industry niche. Shoppers will flock to your store to buy goods so you need to have sufficient merchandise to meet customer demand. Implementing retail inventory management reduces costs and offers a better understanding of the sales process.

Inventory calculation tools give retailers viable information like:

- Total product categories, locations, and quantity.

- Profit margin as per product line, model or item.

- The ideal amount of inventory to order and store.

- Identifying the best-selling stocks and low-performing stocks to eliminate backlogs and reduce skyrocketing holding costs.

Effective stock administration decreases the chance of stockouts and overloading, thus boosting functional productivity and customer satisfaction.

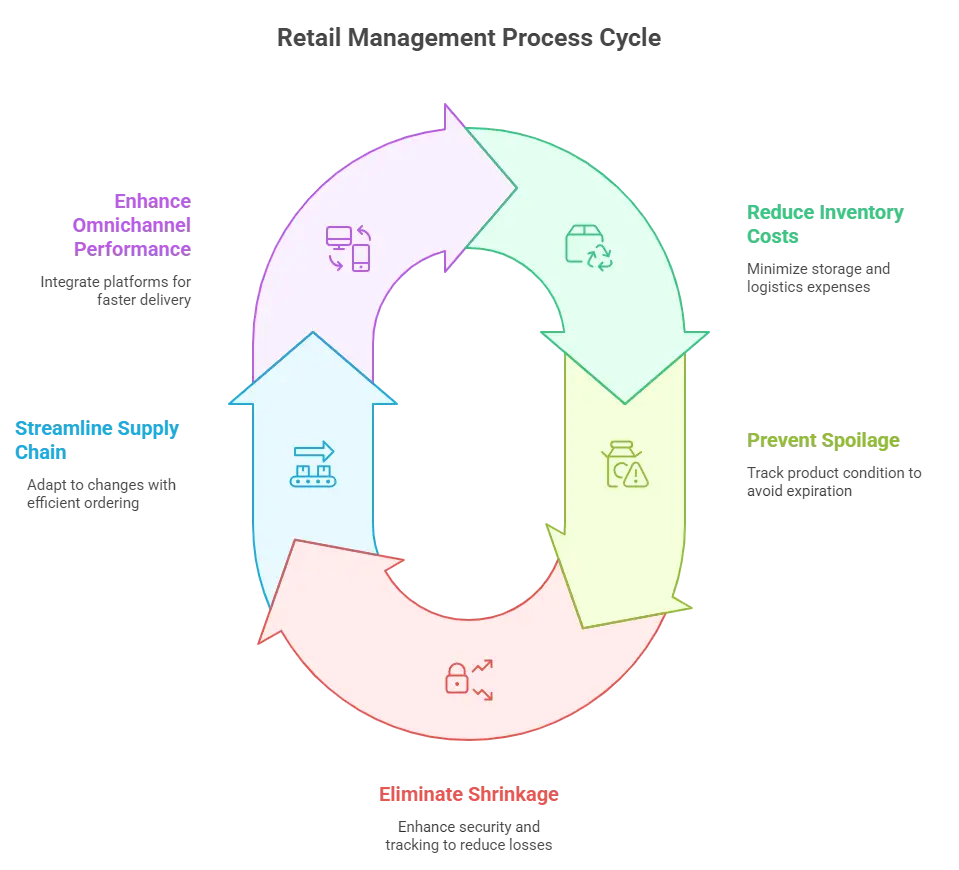

The Importance of Retail Management Process

From a strategic viewpoint, the importance of the retail process can be outlined in the following ways.

1. Lesser Inventory Cost

As a store manager, you need to possess a bird’s eye view of the inventory level. Pinpointing them accurately helps you reduce storage and carrying costs for redundant merchandise. Eliminating excess inventory also decreases costs related to logistics, shipping, depreciation, and other opportunity costs.

2. No Spoilage and Obsolete Items

Retail inventory management helps retailers address cost bottlenecks related to product expiration. Many items and perishable goods have less shelf life and if customer preferences change, the product will become obsolete. Tracking the product condition at the beginning sets a stricter standard reducing chances of expiration.

3. Zero Shrinkage

Inventory loss is a recurring issue causing problems at the retailer and customer’s end. Shoplifting, vendor mistakes, employee theft, product damage, and fraud are the leading causes of shrinkage. Retailers lose sales opportunities and most losses are due to incorrect inventory tracking and recording.

Store inventory management can reduce shrinkage and enhance worker productivity and monitoring, boosting sales capacity.

4. Easy Supply Chain Process

Monitoring inventory and sales trends helps you streamline your supply chain operations. Having this information beforehand gives you the flexibility to adapt to changes. You can use stock replenishment methods like Just-in-time ordering or bulk order facilities to forecast demand and expenses.

Retail inventory management calculates the ideal order size of your store so customers get the products they want with fewer mistakes.

5. Enhanced Omnichannel Performance

Seamless omnichannel performance helps you tap into multiple sales checkpoints through integration on a single platform. Most retailers are unable to manage inventory count across all the platforms, causing customer disruption. Simplified access to accurate inventory data helps you to deliver the product faster to your customers.

Let’s jog your memory and understand the types of retail inventory strategies.

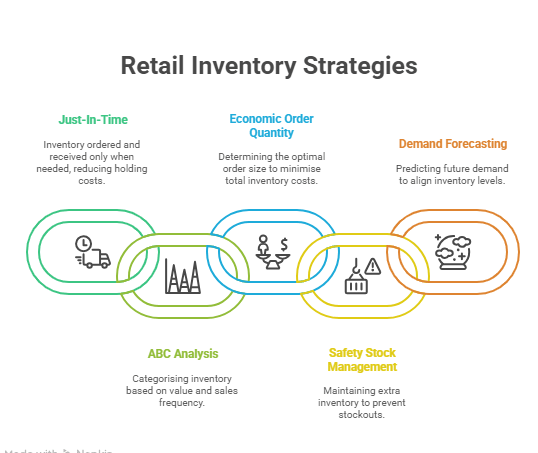

The Top 5 Retail Strategies

Inventory management strategies synchronise stock movement across the supply chain operations. Look at the top 5 retail inventory strategies revolutionising the logistics industry.

1. Just-In-Time (JIT) Inventory Management

Just-In-Time (JIT) inventory management is a strategy where inventory is ordered and received only as needed for production or sales. This approach minimises holding costs and reduces the risk of overstocking. By closely coordinating with suppliers, retailers can ensure they have the necessary inventory without excessive surplus. This strategy requires a reliable supply chain and accurate demand forecasting to prevent stockouts.

2. ABC Analysis

ABC analysis is an inventory categorisation technique that segments inventory into three categories based on their importance and value. Category A consists of high-value items with low sales frequency, Category B includes moderate-value items with moderate sales frequency, and Category C comprises low-value items with high sales frequency.

This classification helps retailers prioritise their inventory management efforts, ensuring that the most valuable items are always in stock and reducing the focus on less critical items.

3. Economic Order Quantity (EOQ)

The Economic Order Quantity (EOQ) model determines the optimal order quantity that minimises the total cost of inventory, including ordering and holding costs. By calculating the EOQ, retailers can identify the most cost-effective order size, balancing the costs associated with ordering too frequently and holding excess inventory. This strategy helps maintain adequate stock levels while minimising total inventory costs.

4. Safety Stock Management

Safety stock management involves maintaining an additional quantity of inventory to mitigate the risk of stockouts caused by demand variability or supply chain disruptions. By keeping a buffer stock, retailers can ensure product availability during unexpected fluctuations in demand or delays in supply.

Determining the appropriate safety stock level requires analysing historical sales data, lead times, and demand variability to find the right balance between service levels and holding costs.

5. Demand Forecasting

Accurate demand forecasting is essential for effective inventory management. By analysing historical sales data, market trends, and seasonal patterns, retailers can predict future demand and adjust their inventory levels accordingly.

Advanced demand forecasting techniques, such as machine learning and predictive analytics, can further enhance accuracy by identifying patterns and trends that may not be apparent through traditional methods. This strategy helps retailers align their inventory with customer demand, reducing stockouts and overstock situations.

Next, let’s understand the best practices to implement a successful retail inventory management solution.

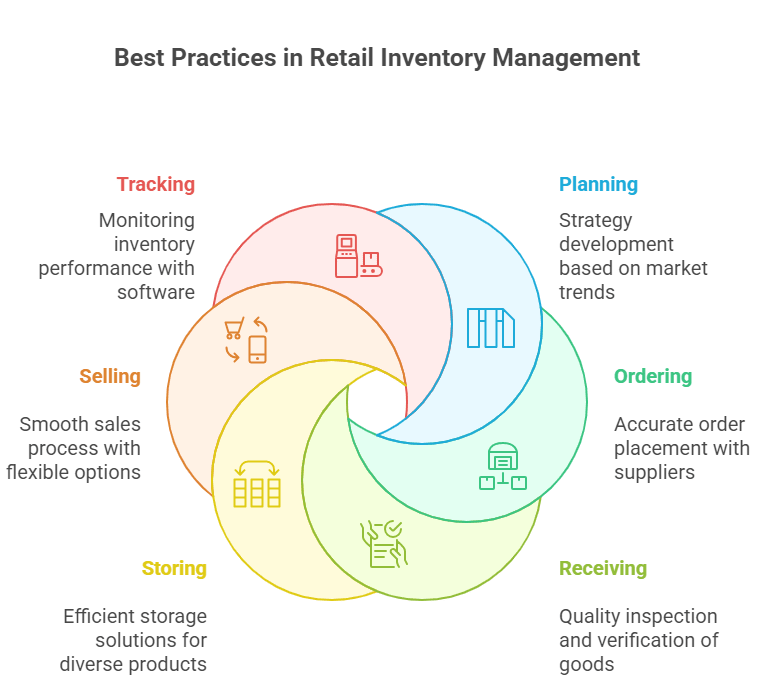

Retail Inventory Management – Best Practices

The merchandise management process is a detailed task encompassing multiple levels. Here is a breakdown of the best practices to implement your inventory solution.

1. Plan a Systematic Procedure

Plan the type of products to buy based on market trends and inventory forecasts. It is critical to develop a strategy that analyses seasonality, sales data, and customer feedback for different products.

2. Advance Order

Place accurate orders to your suppliers, vendors, and other stakeholders. A developed retail inventory management strategy has a solution that matches your demand, current inventory levels, and supplier lead time.

Keep track of your purchase orders to manage inventory on the go.

3. Receiving the Packages

Quality inspection and verification are the core of any inventory management solution. Once the products arrive at the warehouse, check the order accuracy. Use tools like scanners, labels, and printers to manage inventory and increase accountability.

4. Store and Sell

Storing your inventory is a game-changer. Ideally, you should store products of different shapes, sizes and shelf lives. Perishable goods require temperature control and dry, cool areas and ventilation, storage bins, and cabinets.

Use pallets, shelving units, and overhead bins to adjust, monitor and, access products anytime you want.

Moreover, the sales process needs to get smoother, faster, and convenient. Use flexible delivery options and POS tools to make transactions easy and allow customers to avail multiple payment methods.

5. Track Inventory

Install a robust retail inventory management software to monitor your inventory performance. Analyse metrics like sales, margin, shrinkage, and turnover to create reports in a single dashboard. Accurate reports identify patterns and simplify end-of-the-year financial draft mandates.

Finally, let’s move to the next part of the blog.

FAQs: Retail Inventory Management: A Complete Guide

1. What is the retail inventory method?

This is an accounting technique for estimating the total value of a retail chain’s merchandise. It provides the end inventory balance by calculating the relative price of the merchandise.

2. What are the inventory management processes?

Managing inventory includes storing, tracking, ordering, and shipping products along the company’s supply chain networks. There is management of raw materials, warehousing and processing of items.

3. What is cycle counting and how does it help in inventory management?

Cycle counting is a method where a small subset of inventory is counted on a specific day, making it easier to audit inventory without disrupting operations. It helps maintain accurate stock levels, reduces discrepancies, and allows for ongoing inventory verification instead of a full physical count.

4. Why is inventory turnover important for retailers?

Inventory turnover measures how quickly a retailer sells and replaces inventory within a given period. A higher turnover rate generally indicates strong sales and efficient inventory management, while a low turnover may suggest overstocking or weak demand.

5. What is just-in-time (JIT) inventory management?

Just-in-time (JIT) inventory management is a strategy where inventory is ordered and received only as it is needed for production or sales, minimizing holding costs and reducing waste. This approach helps retailers optimize stock levels and improve cash flow.

6. How do barcode scanners improve inventory control?

Barcode scanners streamline inventory tracking by quickly and accurately recording product information, reducing manual errors, speeding up checkouts, and making it easier to update stock levels in real time.

7. What are common causes of inventory shrinkage?

Inventory shrinkage typically results from theft (by customers or employees), administrative errors, supplier fraud, or damaged goods. Retailers use security measures and inventory audits to minimize shrinkage.

8. How can retailers optimize their inventory levels?

Retailers can optimize inventory levels by using demand forecasting, monitoring sales trends, implementing inventory management software, and maintaining good relationships with suppliers to ensure timely restocking.

9. What is the difference between perpetual and periodic inventory systems?

A perpetual inventory system continuously tracks inventory levels using technology, providing real-time updates. A periodic inventory system relies on physical counts at specific intervals, which can be less accurate and more labor-intensive.

10. How does inventory management affect customer satisfaction?

Effective inventory management ensures that popular products are always in stock, reducing out-of-stock situations and minimizing wait times for customers. This leads to higher customer satisfaction and increased sales.

Conclusion

Retail inventory management is a regular process for streamlining the operations of your retail store. Incorporating the best practices and installing automation are some of the ways to ensure operational efficiency at the backend so customer satisfaction remains high. For optimum inventory tracking solutions, connect with Qodenext today.