Managing inventory efficiently is a balancing act that every business needs to master. Order too much, and you’re stuck with excess stock that takes up space and ties up capital. Order too little, and you risk stockouts, delayed deliveries, and unhappy customers. This is where understanding your reorder level comes into play.

Think of the reorder level as your inventory’s safety net. It’s the point at which you know it’s time to place a new order, ensuring products are available when your customers need them. Knowing how to calculate and manage your reorder level helps you stay one step ahead, avoiding both overstocking and stockouts.

In this blog, we’ll explore what is reorder level, why it’s so essential, and how to calculate it using a simple formula. You’ll also learn how to adapt your reorder level to different circumstances and see practical examples along the way.

Let’s dive in!

What Is Reorder Level?

Reorder level refers to the predetermined inventory threshold at which a business needs to place a new order for replenishing stock.

When inventory reaches this level, it triggers a reorder to ensure stock availability by the time demand arises.

Imagine a retailer selling mobile accessories. If the reorder level for phone chargers is set at 100 units and the current stock reaches that number, a new order is placed to replenish the inventory before it depletes further.

Now that we know what a reorder level is, let’s explore why it’s so important for your business.

Why Is Reorder Level Important?

Understanding the importance of reorder level can significantly enhance inventory efficiency.

Here’s why it matters:

- Prevents Stockouts

It ensures products are always available, reducing the risk of losing sales.

- Efficient Inventory Management

Businesses can streamline operations by maintaining optimal stock levels.

- Improved Customer Satisfaction

On-time order fulfillment results in happy customers.

- Cost Control

Reduces storage and holding costs by avoiding overstocking.

In short, a well-calculated reorder level helps you operate smoothly, fulfill customer demands, and minimize inventory-related expenses.

Now that we’ve established its importance, let’s move on to how you can calculate it.

Reorder Level Formula

The reorder level formula is simple and effective for maintaining efficient inventory levels. It is calculated using the following formula:

Reorder Level = Lead Time Demand + Safety Stock

Where:

- Lead Time Demand: The number of units expected to be sold during the lead time.

- Safety Stock: Extra inventory kept as a buffer to cover unexpected demand or supply chain delays.

Having the right safety stock is crucial, especially in industries where demand can fluctuate or supply chain issues may arise.

Now that we understand the formula, let’s break it down further with step-by-step instructions.

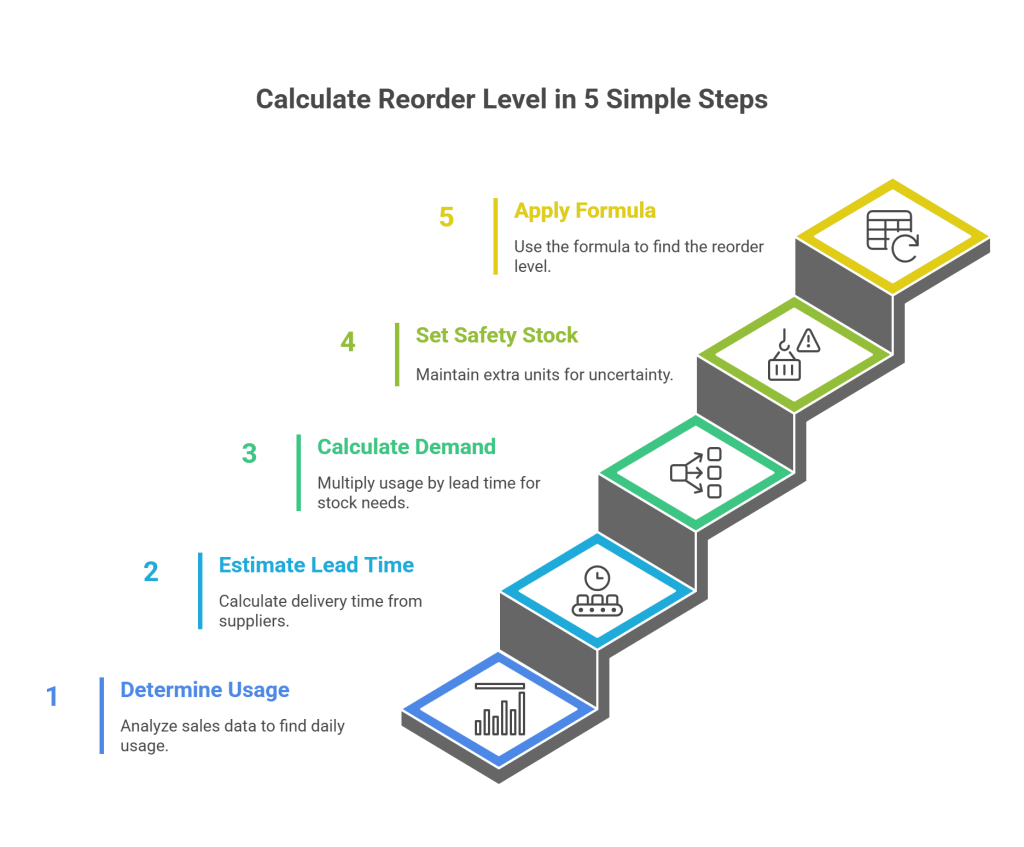

How to Calculate Reorder Level in 5 Simple Steps

To calculate the reorder level efficiently, follow these five easy steps:

- Determine the Average Daily Usage: Identify how many units of a product are sold or used daily. Analyze past sales data to get an accurate number.

- Estimate the Lead Time: Calculate how many days it takes for your supplier to deliver an order once it is placed.

- Calculate Lead Time Demand: Multiply the average daily usage by the lead time. This gives you a reliable estimate of how much stock you’ll need during the waiting period.

- Set Safety Stock: Maintain additional units as a safety buffer. The amount can vary depending on the product and demand uncertainty. Safety stock acts as a cushion for unforeseen circumstances.

- Apply the Formula: Use the reorder level formula to calculate the reorder level.

Example:

- Average Daily Usage: 50 units

- Lead Time: 7 days

- Safety Stock: 100 units

Reorder Level = (50*7) + 100 = 450 units

This means when your stock reaches 450 units, it’s time to reorder.

With the formula clear, let’s see how different scenarios can impact your reorder level calculation.

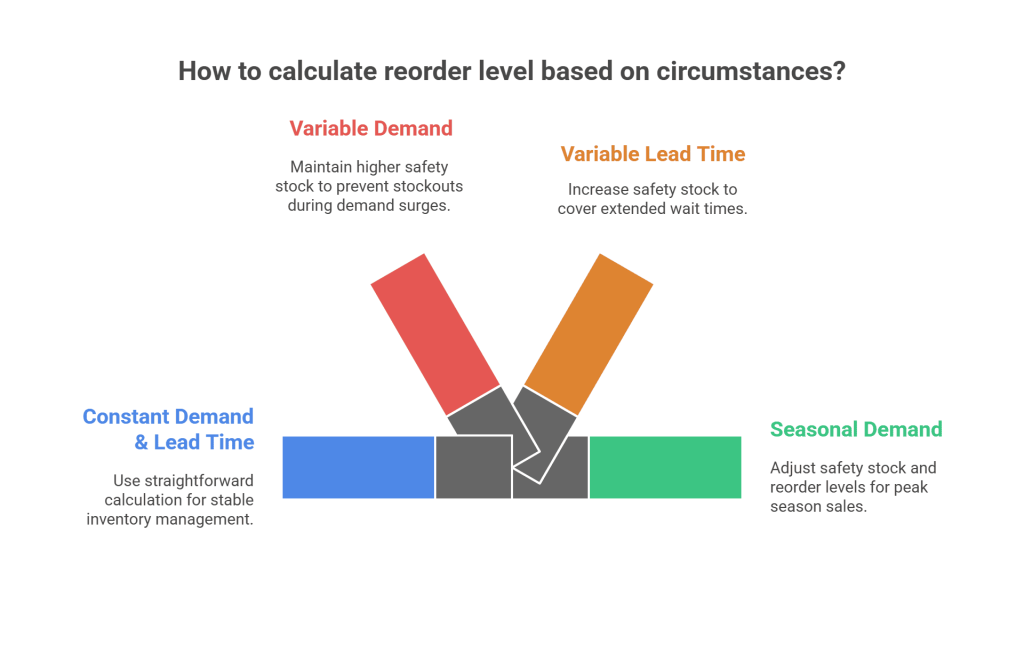

Reorder Level Calculation in Different Circumstances

The reorder level may vary under different circumstances, such as fluctuating demand, unpredictable lead times, or seasonal changes. Let’s explore some scenarios:

1. Constant Demand and Lead Time

When both demand and lead time remain stable, a straightforward calculation using the formula works best. This scenario is common in industries with predictable sales patterns.

2. Variable Demand with Fixed Lead Time

If demand varies, it’s advisable to maintain higher safety stock to prevent stockouts. For example, businesses selling fashion items may see sudden surges in demand during festive seasons.

3. Variable Lead Time with Stable Demand

In cases of uncertain lead times, increasing safety stock ensures you have enough inventory to cover extended wait times. This is common in international supply chains where shipment delays are possible.

4. Seasonal Demand

During peak seasons, safety stock and reorder levels should be adjusted to account for higher sales volume. Seasonal businesses like winter apparel brands often increase their reorder levels before the season begins.

Understanding how to adapt in different scenarios ensures your inventory management remains flexible and efficient.

Difference Between Reorder Level and Reorder Quantity

While both terms are closely related, they serve different purposes in inventory management.

- Reorder Level: The inventory point at which a new order should be placed.

- Reorder Quantity: The specific amount of stock that should be ordered once the reorder level is reached.

In simpler terms, the reorder level is the trigger point, while the reorder quantity determines how much to restock.

Example:

- Reorder Level: 450 units

- Reorder Quantity: 700 units

When stock falls to 450 units, a purchase order for 700 units is placed.

FAQs: Reorder Level in Inventory Management: What It Is and How to Calculate

1. What happens if I don’t maintain a reorder level?

You risk stockouts, delayed shipments, and dissatisfied customers, which can negatively impact your business reputation and revenue.

2. Can the reorder level change over time?

Yes, it should be regularly adjusted based on changes in demand patterns, lead time variations, and market conditions.

3. How often should I calculate the reorder level?

Review it monthly or quarterly, depending on the volatility of your sales and supply chain.

4. What’s the best tool to calculate reorder levels?

Inventory management software with automated reorder point calculations can simplify the process.

5. How does reorder level help in lean inventory management?

It minimizes excess stock while preventing stockouts, ensuring a lean and efficient inventory system.

Conclusion

Mastering the concept of reorder level in inventory management can significantly impact your business’s operational efficiency. By applying the correct formula, monitoring your stock levels, and adapting to changing circumstances, you can ensure uninterrupted operations and happy customers.

Now that you have a clear understanding of what is reorder level and how to calculate it, consider reviewing your inventory strategy to optimize your reorder points effectively.