Inventory management plays a vital role in ensuring smooth business operations. To manage resources efficiently and deliver goods on time, it’s important to understand the difference between process vs progress, two terms that are often confused but carry distinct meanings.

Many professionals struggle with phrases like work in progress or process or wonder whether to use in process or in progress in different contexts. While these may sound similar, they are used in very specific ways depending on the situation.

In simple terms, work-in-progress usually refers to long-term projects such as construction or large-scale development, whereas work-in-process is often used in manufacturing, where goods move quickly through production.

In this blog, we’ll break down the nuances of process vs progress, clarify how these terms differ, and guide you on when to use them correctly. Let’s begin by exploring the meaning of “Work in Progress.”

• What is Work in Progress Inventory?

Many businesses confuse work in progress or process, but work in progress, sometimes referred to as assets, requires a considerable amount of time to complete. There is an underlying assumption in work in progress that there is a larger project framework that requires a heavier investment in time for the process.

While certain companies may opt for specialised general ledger accounts for construction projects, a substantial build can still be classified as an instance of work in progress.

You also report work in progress on your company’s balance sheet. As additional billings are incurred, the value of the work in progress account increases. A company may determine the asset’s fair market value (FMV) assessment as a part of its annual financial reporting requirements.

Take a 40-story skyscraper for example. It is 75% complete; it might justify a company recognising supplementary financial gains beyond costs through a Fair Market Value (FMV) adjustment in process meaning.

Examples of Work in Progress

(All these instances are hypothetical and fictional. They are presented to merely help you understand how the inventory works.)

Here are a few instances of work-in-progress inventory:

Example 1:

A motorcycle manufacturer, Heritage Rides, builds and sells vintage bikes for private collectors. Building each bike takes four weeks- from constructing to adding the final details.

At the end of the month, Heritage Bikes counts its present inventory which shows 20 bikes. They also see five incomplete bikes. The company will account for the incomplete bikes as ‘work in process’.

Example 2:

Sunshine Metalworks manufactures custom iron and steel parts like wrought iron railing and high-end doorknobs for domestic purposes. The company accounts for its assets each quarter. At the end of the quarter. Sunshine Metalworks finds that it has completed 300 orders and has 40 remaining in the manufacturing process. It counts those unfinished products as ‘work in process’.

Example 3:

Haute Bridal Couture, a wedding dress shop, is evaluating its inventory and assets. While the company has 53 wedding dresses completed, it also has 7 incomplete dresses. The dressmakers have completed the designs, cut the fabric and started the sewing for these dresses, but are yet to complete them. These unfinished goods are the shop’s work in process.

With that, let’s see how the former fares in this comparison of process vs progress.

• What is a Work in Process Inventory?

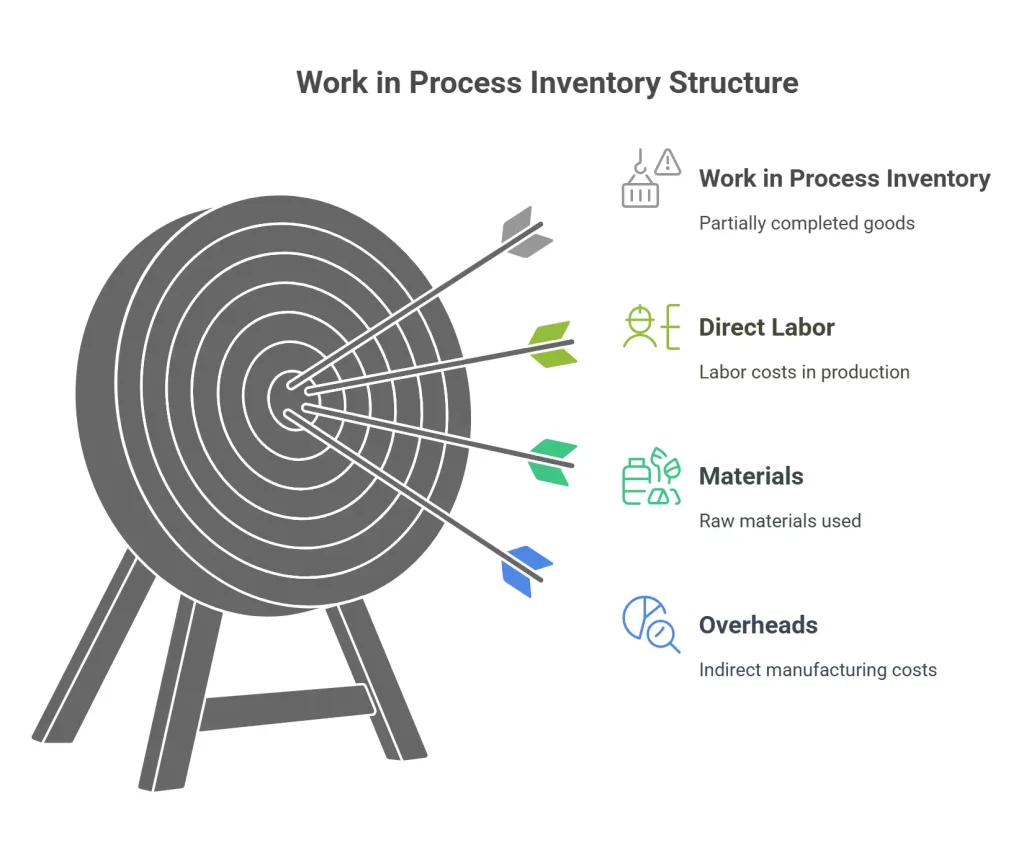

Unlike work in progress, work in process inventory focuses more on products moving through production lines. This is where the debate of work in progress or process becomes important. Work in process refers to partially completed goods. They have another name: goods-in-process. These goods are the raw materials that move to become a finished product over a period.

You can find the inventory for this on the balance sheet of a manufacturing company. Thai accounts of inventory like the work in progress may include direct labour, materials and overheads for manufacturing.

Companies frequently employ internal allocation methods to ascertain the approximate financial worth of work in progress. This entails not only evaluating the financial value of unfinished goods but also estimating the percentage of completion for its products.

So, let’s see how the former works in this debate of process vs progress.

Examples of Work in Process

(All these instances are hypothetical and fictional. They are presented to merely help you understand how the inventory works.)

Here’s how you can see work in process in real-time inventories:

Example 1:

Saturn Computers, an advanced computer manufacturing firm, signs a contract with the government to create processors for use in new public spacecraft design. After having preliminary planning, they say that the project timeline is two years.

Due to the lengthy time of the project, both parties agree that Saturn Computers can earn a percentage of its pay at six different progress stages throughout the two-year time. When reporting its earnings, the computer manufacturing firm counts the product as a work in progress.

Let’s see two more examples to better understand the difference between process vs progress.

Example 2:

Jon’s Construction Firm is planning a year-long project to construct a high-end apartment building. Opting for an incremental billing approach, Jane’s Construction invoices the client every quarter. In their accounting practices, they gauge the project’s costs and value using a work-in-progress methodology.

Example 3:

Charisma Motors, a commercial car manufacturer, focuses on producing sedans, cross-overs, and SUVs. Within their manufacturing plant, vehicles progress along an assembly line, navigating various workstations where engineers install and secure new components. To manage finances, Charisma Motors predominantly categorises a significant portion of its car inventory as work in progress for accounting purposes.

Understanding the basic difference between ‘process’ and ‘progress’,

• Calculating Work in Process vs Progress

There are formulas for calculating the two types of inventory:

Work in Process Formula

[Beginning WIP Inventory + Manufacturing Costs – COGM = Ending WIP Inventory]

Examples:

This type of inventory could be undergoing finishing touches before being marked as complete. It has three stages- a current asset on the balance sheet, which you can classify into:

- Raw Materials: Materials on hand that are part of the production process, like commodities.

- Work in Progress (WIP): The process of converting the raw materials into finished goods, but the item is not yet ready for sale.

- Finished Goods: Production is complete and these items are ready for sale.

Once a product is designated as a finished good and subsequently sold, the corresponding amount is deducted from the inventory balance on the balance sheet.

Work in Progress Formula

Here is how you calculate work-in-progress inventory with this formula – in the specific context of a manufacturer – is as follows.

[Ending Work in Progress = Beginning WIP + Manufacturing Costs – Cost of Goods Manufactured]

This is the essence of inventory management with the two types of inventory: work in process vs work in progress.

• Overview of the Difference Between Work In Process and Work In Progress

Here is a quick rundown of the main differences between process and progress inventory management:

| Aspect | Work in Process (WIP) | Work in Progress (WIP) |

| Definition | Goods in various stages of production | Unfinished tasks within a project |

| Time Frame | Typically involves manufacturing processes | Typically involves time-consuming projects like construction |

| Focus | Emphasises the production flow and stages | Emphasises the overall progress of a project |

| Industries | Usually used in manufacturing and production sectors | Preferably seen in construction, software development, and other project-based industries |

| Examples | Assembly lines, production floors | Building construction, software development, infrastructure projects |

| Monitoring and Control | Requires tracking of production stages and inventory levels | Requires tracking of project milestones and completion stages |

Developers and manufacturers transform raw materials into finished goods, adapting their reporting methods-process vs progress based on the project’s scale, whether opting for work in process or work in progress reporting.

• Conclusion

Understanding the nuances between process vs progress is essential for businesses that want accurate inventory tracking and efficient operations. While both work in process and work in progress share the WIP acronym, they highlight very different stages: manufacturing cycles versus long-term projects. Knowing when to use terms like work in progress or process or in process or in progress ensures clear communication, precise accounting, and better decision-making.

At Qodenext, we help businesses simplify these complexities by applying the right methodologies for inventory management. With expert guidance, companies can streamline production, improve reporting accuracy, and ultimately strengthen their financial performance.

• FAQs: Process Vs Progress

1. What is the difference between process and progress?

A process is a series of actions taken to achieve a result, while progress refers to the advancement towards a goal.

2. What is the WIP formula?

The WIP formula is:

WIP = Beginning WIP + Manufacturing Costs – Cost of Goods Manufactured

3. How to find ending work in process inventory?

Ending work in process inventory is found by adding the beginning WIP to manufacturing costs and subtracting the cost of goods manufactured.

4. How does work in process help inventory?

Work in process aids inventory by tracking production stages, optimising resource allocation, and ensuring efficient manufacturing processes.

5. What is ABC analysis?

ABC analysis categorises inventory items based on their importance, typically classifying them as A (most valuable), B, or C (least valuable) items.

6. What is the difference between Work in Process and Work in Progress?

Work in Process refers to items undergoing short-term manufacturing (like on an assembly line), while Work in Progress typically refers to longer-term, project-based work like construction.

7. Why do both terms share the same acronym (WIP)?

Despite having different contexts, both terms involve partially completed work and share similar accounting treatment, hence the common use of the acronym WIP.

8. Is Work in Progress used only in the construction industry?

While commonly associated with construction, Work in Progress also applies to long-term projects in sectors like software development, shipbuilding, and aerospace manufacturing.

9. How is Work in Process accounted for in financial statements?

It appears as a current asset on the balance sheet and includes costs like raw materials, labor, and manufacturing overhead incurred up to that point.

10. What types of businesses typically use Work in Process inventory?

Manufacturing businesses with short production cycles, such as automotive companies or electronics manufacturers, frequently use Work in Process to track partially finished goods.

11. Can a single company use both Work in Process and Work in Progress?

Yes, companies handling both short-term production and long-term projects may use both terms depending on the nature of each operation.