In a globalized industry, the demand for temperature-sensitive products, ranging from vaccines and pharmaceuticals to fresh produce and frozen foods, is steadily growing. Ensuring these products are delivered safely and remain within specific temperature thresholds throughout transit is the core of cold chain logistics. Any deviation, however minor, can compromise product quality, safety, and shelf life. This is where smart monitoring devices step in as game-changers.

Smart monitoring technology is revolutionizing storage logistics by offering real-time data visibility, predictive analytics, and proactive intervention. In this blog, we will explore how these technologies optimize cold chain processes and prevent costly spoilages or compliance issues.

What Is Cold Chain Logistics?

Cold storage logistics refers to the transportation, storage, and handling of temperature-sensitive goods through a supply chain that maintains a consistent temperature range. It is essential for industries such as:

- Pharmaceuticals (especially vaccines, insulin, and biologics)

- Perishables (dairy, meat, seafood, fruits, and vegetables)

- Chemicals and lab reagents

Each product category has strict regulatory requirements and must remain within prescribed temperature brackets; failure to comply can lead to degradation, recalls, or health hazards.

The Challenges in Cold Chain Logistics

Despite technological advances, storage logistics faces persistent challenges:

- Temperature Excursions: Even brief fluctuations during transit can render products unusable.

- Lack of Visibility: Traditional systems often lack real-time location and condition tracking.

- Manual Errors: Relying on manual logging increases the risk of oversight.

- Regulatory Compliance: Industries must meet guidelines like the FDA, WHO, and GDP standards.

- Delayed Notifications: By the time a breach is identified, it’s usually too late to salvage the shipment.

To overcome these challenges, logistics providers are increasingly adopting smart monitoring devices that ensure transparency, control, and compliance across the supply chain.

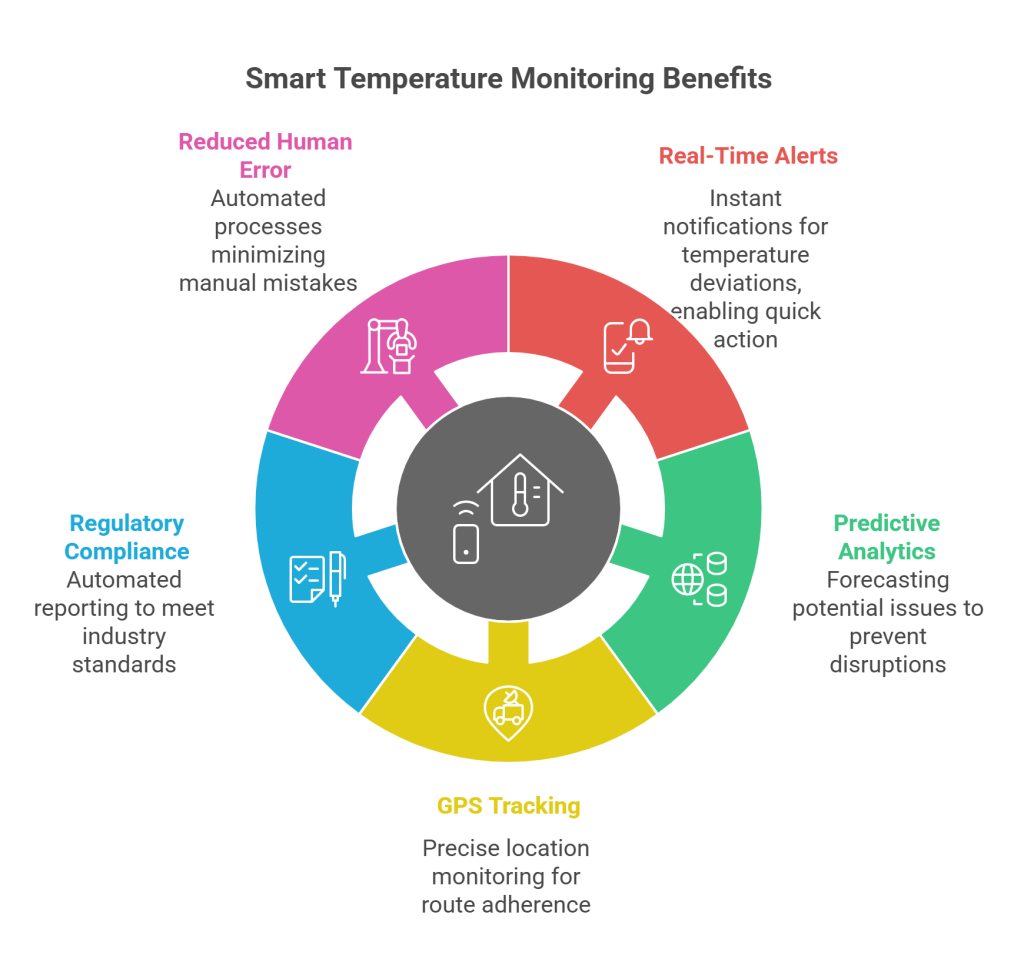

Smart Temperature Monitoring Systems: A Game-Changer

Smart monitoring devices are IoT-enabled sensors and systems that collect and transmit critical data in real-time. These tools monitor variables such as:

- Temperature

- Humidity

- Light exposure

- Shock or vibration

- Geolocation (GPS)

Here’s how they are transforming cold chain logistics:

1. Real-Time Temperature Tracking

Smart temperature sensors continuously monitor the temperature inside refrigerated trucks, containers, and warehouses. If a shipment veers out of range, alerts are sent instantly to key personnel. This enables quick action to prevent product spoilage.

For instance, a pharmaceutical company shipping insulin can receive immediate alerts if the product’s temperature crosses 8°C. With actionable data, the logistics team can reroute or replace affected products before they reach consumers.

2. Predictive Analytics for Preventive Action

Advanced monitoring systems use machine learning to predict potential issues before they occur. By analyzing historical data, route conditions, and ambient temperatures, these systems forecast risks and suggest optimal routes or timing.

Predictive analytics also assists in maintenance planning. If a reefer unit (refrigerated container) shows signs of malfunction, smart systems can recommend servicing before a breakdown occurs, ensuring uninterrupted cold chain logistics.

3. GPS and Geofencing Capabilities

Smart monitoring devices come with built-in GPS and geofencing features. This allows logistics managers to:

- Track the shipment’s exact location

- Verify that shipments remain on the correct route

- Set virtual boundaries and get alerts if a shipment deviates from its path

Geofencing helps maintain route discipline, prevents unauthorized stops, and ensures timely deliveries—all crucial for maintaining cold chain integrity.

4. Regulatory Compliance and Automated Reporting

Many industries require proof of temperature control throughout the supply chain. IoT in cold supply systems automatically generates tamper-proof logs that document temperature, humidity, and route data in compliance with global standards.

This data not only aids audits but also boosts brand credibility and customer trust. Whether you’re dealing with the FDA, MHRA, or EMA, automated reporting reduces the burden of manual documentation in storage logistics.

5. Minimized Human Error

Manual processes are prone to missed checks, improper documentation, or delayed alerts. Smart devices eliminate these risks by automating data collection and transmission, thus reducing human intervention and the likelihood of oversight.

Furthermore, these systems ensure consistency across different regions and personnel, providing standardization in storage logistics operations.

Case Study: Cold Chain Optimization for a Vaccine Distribution Network

During the COVID-19 vaccine rollout, governments and pharmaceutical companies partnered with cold chain logistics providers to ensure safe delivery across geographies. In many cases, smart sensors embedded in vaccine containers provided real-time data to centralized dashboards.

If a temperature breach occurred in transit, immediate action was taken to reroute, repackage, or alert nearby fulfilment centers. This level of monitoring significantly reduced wastage and ensured safe immunization across vast populations.

Cost-Benefit Perspective

While the upfront investment in smart monitoring devices may seem high, the long-term savings outweigh the costs. Benefits include:

- Fewer spoilage-related losses

- Reduced product recalls through traceability software

- Enhanced customer trust

- Better resource utilization

- Increased compliance and audit readiness

Ultimately, optimizing logistics with smart devices leads to greater operational efficiency and customer satisfaction.

Integration with Warehouse and Fleet Management Systems

Smart monitoring devices can be integrated with broader warehouse management systems (WMS) and transport management systems (TMS). This creates a unified storage logistics platform where real-time data flows seamlessly across procurement, warehousing, and distribution.

Through integration, companies gain end-to-end visibility and can automate corrective workflows based on real-time conditions.

The Future of Storage Logistics

As technology advances, expect to see the following trends:

- Blockchain Integration: Ensures immutable records of product handling.

- AI-Powered Decisions: AI will analyze big data for dynamic rerouting and optimization.

- Energy-Efficient Devices: Longer battery life and solar-powered sensors for long-haul shipments.

- Enhanced Edge Computing: Smart devices will make local decisions without needing constant internet access.

All these innovations will contribute to a more resilient, sustainable, and efficient refrigerated logistics ecosystem.

FAQs: Cold Chain Logistics

1. What is the biggest advantage of using smart monitoring devices in cold chain logistics?

Real-time visibility. It allows proactive management of temperature excursions and ensures product integrity throughout the supply chain.

2. Are these devices suitable for all types of shipments?

Yes, they can be customized for pharmaceuticals, food, chemicals, and more. Each device can be calibrated according to the product’s specific temperature and humidity requirements.

3. How do these devices ensure regulatory compliance?

They generate digital logs that serve as audit trails. These logs meet global compliance standards like GDP, FDA, and WHO guidelines.

4. Can they function in areas without internet access?

Many modern devices use GSM networks and can store data locally, uploading it once connectivity resumes. Some also use satellite communication for remote areas.

5. How do smart monitoring devices contribute to sustainability?

By reducing spoilage and waste, these devices minimize the carbon footprint associated with product recalls, re-shipping, or disposal.

6. Is the investment in smart monitoring justified for small-scale businesses?

Yes, even small businesses benefit from reduced spoilage, fewer customer complaints, and easier compliance—all leading to long-term savings.

Conclusion

Cold chain logistics is no longer just about insulated trucks and refrigerated warehouses; it’s about intelligence, responsiveness, and transparency. Smart monitoring devices are elevating the industry from reactive to proactive, ensuring products reach their destination safely and within specification.

By integrating these technologies into their supply chains, businesses can optimize operations, reduce risks, and build resilient logistics networks fit for future demands. Want to automate supply chain traceability? Contact Qodenext today.