In the mining and quarrying industry, prioritizing efficiency and safety is essential, especially concerning the movement of extracted materials. Among the innovations that have reshaped these sectors, the conveyor belt in mines stands out.

It has changed the way of material transportation in mining and quarrying operations by increasing their productivity and decreasing labor and safety hazards. Mining conveyor belts have changed the material transportation process in heavy industrial operations by making the process more efficient and safe. It occurs by moving excited materials efficiently from one place to another without any human labor within the process and low risk of any kind of accidents. The role of Mining conveyor belt manufacturers has been crucial in advancing these technologies.

A Brief History of the Mining Conveyor Belt

Conveyor systems were used in mining and quarrying as long ago as the late 19th century, as coal, minerals and aggregates became more and more in demand. Earlier conveyor belt materials were leather or canvas. People turn it by hand manually. With modernization and the power of the industry these days, the conveyor belts in the mines are developed from time to time. .This progress is largely driven by leading Mining conveyor belt manufacturers worldwide.

Functioning

Conveyor belts that you see in mining and quarrying share similarities with those in other industries. They have a continuous loop of durable material, driven by a motor, which moves along pulleys to transport materials.

However, in the mining and quarrying industry, the mining conveyor belts are usually more robust. They can withstand harsh environments and heavy loads. A conveyor belt in mines is specially designed to handle extreme loads and rough environments.

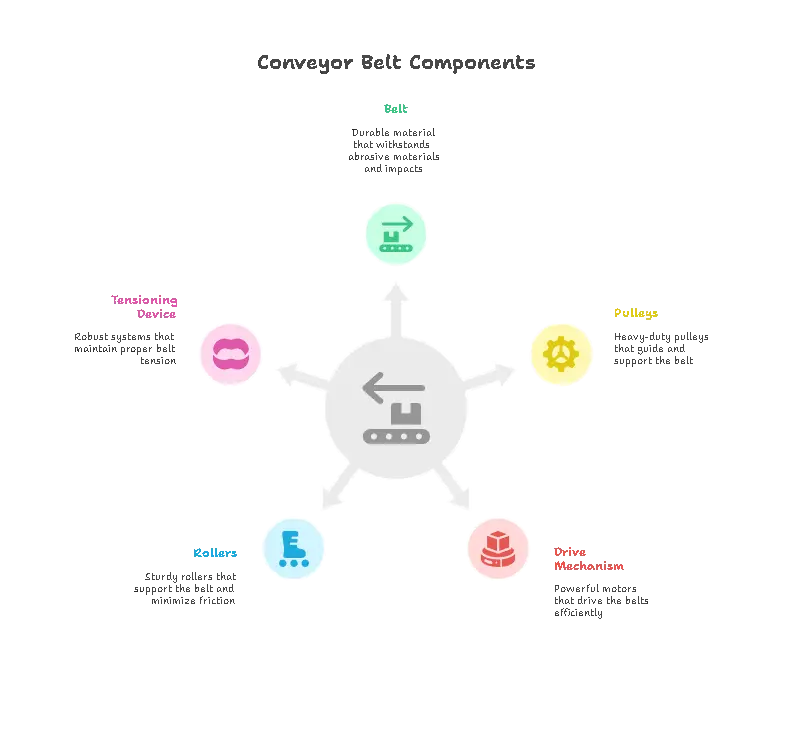

Components of a Conveyor Belt in Mines

Here is a list of the must-have parts in a conveyor belt:

1. Belt:

The belt comprises durable materials like rubber or PVC with special reinforcement. This helps it to withstand abrasive materials and resist impacts.

2. Pulleys:

Heavy-duty pulleys guide and support the belt. It enables smooth movement even under high loads and harsh conditions.

3. Drive Mechanism:

There are powerful motors that drive the belts, allowing for efficient transportation of heavy materials over long distances and steep inclines.

4. Rollers:

Sturdy rollers that have bearings provide support to the belt and minimize friction. This ensures smooth operations.

5. Tensioning Device:

Conveyors in mining and quarrying require robust tensioning systems. This maintains proper tension, preventing belt slippage and ensuring reliable operation.

With that let’s see some of the real-life applications of belt conveyor systems for coal handling.

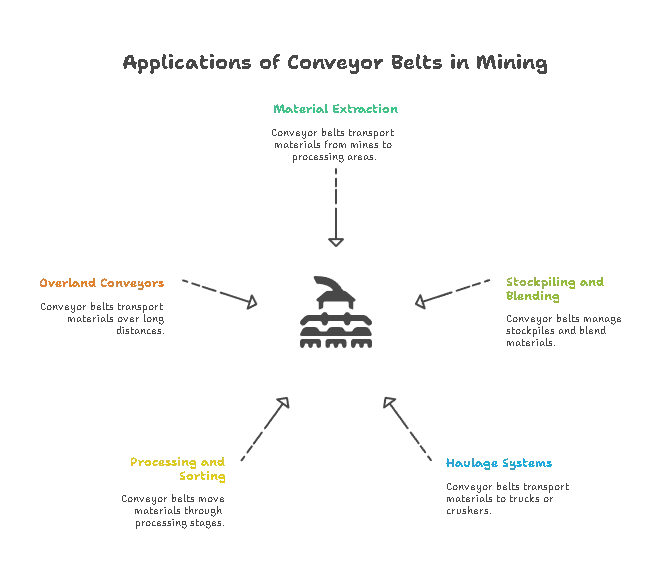

Applications of a Conveyor Belt in Mines

Here are a few ways the coal mine conveyor belt systems play their role in the industrial space. These are the types of conveyor belts used in mining:

• Material Extraction

Conveyor belts are crucial for transporting extracted materials from the mining or quarrying site to the processing area. They effectively replace manual labour, reducing the risk of accidents and increasing operational efficiency. Different types of conveyor belts used in mining are selected depending on the ore or material type

• Stockpiling and Blending

Conveyor belts help in stockpiling of materials. This enables efficient management of stockpiles and consistent blending of various materials for downstream processing. Modern solutions provided by Mining conveyor belt manufacturers ensure reliability in such processes.

• Haulage Systems

Conveyor belts use the haulage systems in the open-pit mines. It helps to transport bulk materials from the excavation site to trucks or crushers. This eliminates the need for costly and time-consuming truck haulage, improving productivity.

• Processing and Sorting

You would need conveyor belts for processing and sorting mined or quarried materials. They transport materials between different stages of the processing plant, including crushing, screening, washing and sizing. Among the various types of conveyor belts used in mining, specialized belts are designed for crushing and screening.

• Overland Conveyors

These automated material-handling conveyors transport large quantities of materials over long distances. They connect mining and quarrying sites. These systems offer cost-effective and energy-sufficient solutions. It reduces the reliance on multiple trucks and minimizes environmental impact.

Advantages of Mining Conveyor Belt

1. Increased Efficiency

A conveyor belt in mines improves material handling efficiency. This, in turn, enables higher production rates. It also reduces downtime associated with manual labor or truck transportation.

Conveyor belts facilitate uninterrupted material flow. Therefore, there is no need for manual loading and unloading, thereby maximizing operational uptime. This continuous operation optimizes productivity by reducing idle time and enhancing overall throughput. This is crucial for meeting production targets efficiently.

2. Enhanced Safety

Automation of material movement and conveyor belts minimizes human contact with heavy machinery. It reduces the risk of accidents and injuries. They also mitigate the dangers associated with truck haulage, such as vehicle collisions and road accidents.

Conveyor systems significantly mitigate the dangers of manual material handling, heavy machinery operation and transportation-related accidents. By automating material movement, they minimize the exposure of workers to hazardous conditions. This decreases the likelihood of injuries.

It helps to create a safer work environment for personnel. Such safety measures also reduce the potential for human errors in material handling processes. This enhances overall safety protocols.

3. Cost Savings

Conveyor belts in mines rescue labor costs and fuel consumption by replacing manual material transportation and truck haulage. It also minimizes product loss and damage during transportation. This is what leads to substantial cost savings. These innovations are possible due to the continuous improvements made by Mining conveyor belt manufacturers.

4. Environmental Benefits

Conveyor systems reduce carbon emissions due to truck transportation. It contributes to a greener and more sustainable mining industry. In many ways, conveyor belts are good for the environment. One such way is how it reduces the need for fuel-consuming trucks and haulage vehicles. It lowers carbon emissions.

Additionally, automatic conveyor belt cleaning systems can have energy-efficient components. These include the regenerative drives and optimized layouts. Such parts minimize the environmental footprint while supporting sustainability initiatives in the mining industry.

5. Versatility and Adaptability

Conveyor belts are pretty customizable for dealing with various materials which include ores, coal, and aggregates. Their variable load capacities, widths, speeds, and dispositions make them adaptable to mining requirements.

They transport various materials efficiently across distances and terrains, optimizing resource utilization and production processes in mining operations by providing flexibility in handling different materials, shapes, and sizes effectively.

Knowing and harnessing all its benefits is one thing, but it is equally important to maintain the upkeep of the conveyor belt.

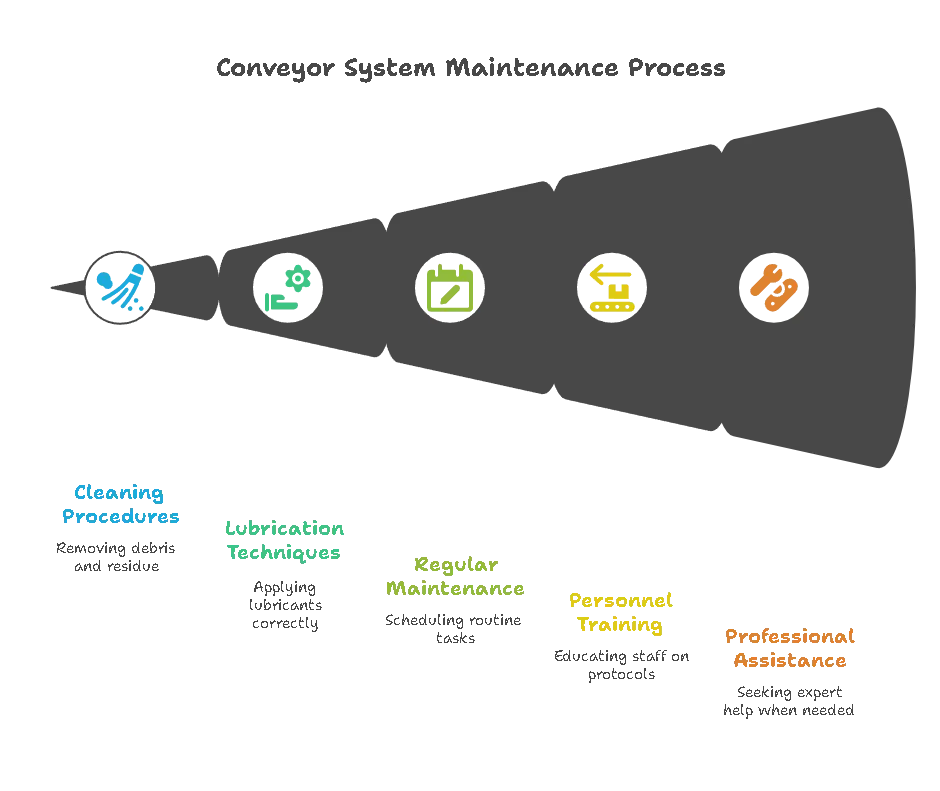

How to Clean and Lubricate a Conveyor System

Inspecting the System: Regularly inspect the conveyor gadget for any signs and signs of damage, harm, or misalignment. Check for any loose parts, including belts, chains, or rollers, and tighten them as vital.

1. Cleaning Procedures

- Remove any debris, dirt, or buildup from the conveyor components using brushes, scrapers, or compressed air.

- Use appropriate cleaning solutions to remove stubborn residue or grease buildup.

- Pay special attention to areas prone to contamination, such as transfer points and pulley assemblies.

2. Lubrication Techniques

- Apply lubricants to the conveyor components in keeping with the producer’s pointers.

- Use the precise type and amount of lubricant for each factor, inclusive of chains, bearings, or gears.

- Avoid over-lubricating.

3. Regular Maintenance Routine

Like all machines it is best to maintain a regular and timely maintenance routine for your industrial conveyor belt in mines. Establish a schedule for routine maintenance tasks. This will ensure that the system remains in optimal condition and operates efficiently over the years.

4. Personnel Training and Documentation

Make sure that staff handling conveyor machine upkeep get hold of thorough training in cleaning and lubrication protocols. Maintain comprehensive information on protection duties, detailing cleaning schedules, lubricant types, and inspection results.

5. Professional Assistance

When unsure about upkeep methods or encountering extensive issues, seek advice from qualified technicians or conveyor machine experts for guidance and help.

Conclusion

A mining conveyor belt plays a huge role in enhancing efficiency and safety when it comes to heavy industrial operations. They have evolved significantly from manual labor to automated systems, optimizing material transportation.

Regular maintenance through training and professional assistance are necessary and choosing trusted Mining conveyor belt manufacturers ensures long-term durability. To understand how the conveyor belt in mines works and what benefits it brings to the supply chain players, stay tuned at Qodenext.

FAQs: Mining Conveyor Belt for Handling Heavy Industry Operations

1. What is the price of a conveyor belt in mines?

The price range usually varies but a horizontal heavy portable conveyor can cost 18,000 INR and upwards.

2. What should you consider before buying a conveyor belt for mine?

The first thing you should decide is the tensile strength requirement, cover thickness, and cover type depending on the material being transported and loaded.

3. What is belt slippage?

This is an occurrence that happens when the conveyor belt and pulley are not aligned. This usually occurs when there is an installation error.

4. What factors should I consider when choosing a conveyor backstop?

Choose common bearings like Pillow block for solid base mounting, corrosion-resistant, best for high loads/speeds. Taper-lock/flange for large vertical/horizontal forces, like wheels. Choose two/four-bolt for a solid base, large loads/shafts.

5. What materials are commonly transported using mining conveyor belts?

Mining conveyor belts are designed to handle a wide range of materials including coal, ore, gravel, sand, and other bulk materials. Their robust construction allows them to operate efficiently even in harsh environments.

6. How do conveyor belts improve safety in mining operations?

Conveyor belts reduce the need for manual handling and vehicle transport, which lowers the risk of accidents and injuries. They also help maintain a cleaner and more organized worksite by streamlining material flow.

7. What factors should be considered when choosing a mining conveyor belt?

Key factors include the type of material being transported, belt length, load capacity, incline angle, and environmental conditions. Selecting the right belt ensures optimal performance and longevity.

8. How often should mining conveyor belts be maintained?

Routine maintenance should be performed regularly, including inspections for wear and tear, checking tension levels, and lubricating moving parts. Preventive maintenance helps avoid unexpected breakdowns and costly downtime.

9. Can mining conveyor belts be customized for specific operations?

Yes, conveyor belts can be tailored to meet specific operational needs. Customizations may include belt width, material composition, drive systems, and support structures to suit different mining environments.

10. What are the environmental benefits of using conveyor belts in mining?

Conveyor belts help reduce fuel consumption and emissions by minimizing the use of heavy transport vehicles. They also contribute to better dust control and lower noise levels, promoting a more sustainable mining process.