How MRP Systems Are Revolutionizing Production Efficiency in 2025

Each factory floor has its own beat, with machines whirring consistently, trained professionals concentrating on the task at hand, and a never-ending battle to get the products delivered on time.

It’s not machines or humans alone that maintain this beat so perfectly; it’s a system that operates unobtrusively to manage all the interlocking pieces behind the scenes.

Your Manufacturing Resource Planning system is that system.

Manufacturers are applying MRP systems to remain agile, profitable, and lean in 2025, when every moment matters and competition is fiercer than ever. MRP is the unsung driving force behind wiser production, be it a small plant or a large organization with operations in numerous countries.

Let’s consider how this system is revolutionizing how well things are produced and why it’s currently the centerpiece of every successful shop floor.

What Is a Manufacturing Resource Planning System?

A manufacturing resource planning system is akin to the virtual command center for your factory.

It maintains your workflow in impeccable order, from acquiring raw materials to delivering them.

In other words, it’s the GPS of manufacturing. It ensures that each step of the process occurs on schedule and doesn’t get clogged up. Older tools only function independently, but newer MRP systems integrate all aspects of a business, from finance to HR to the supply chain to even customer demand, into one smooth system.

It’s time to investigate how warehouse management systems and sound warehousing practices can integrate with your MRP system to provide you with complete visibility if you’re still tracking by hand or through tools that don’t communicate with one another.

Why MRP Systems Are Non-Negotiable in 2025

Static reports and spreadsheets are history for manufacturing.

Contemporary factories must be quick, adaptable, and accurate, and an MRPRODP planning system provides them with all three.

This is how it puts you in the lead:

| 2025 Challenge | MRP-Driven Solution |

| Sudden demand spikes | Real-time forecasting adjusts production instantly |

| Delayed material deliveries | Automated supplier alerts prevent stockouts |

| Long lead times | Smart scheduling and resource allocation reduce delays |

| Lack of visibility | Unified dashboards connect every department in real time |

MRP turns complicated processes into reliable, streamlined workflows by blending automation, analytics, and real-time insight.

They are becoming smarter, more connected, and more critical than ever as digital transformation remakes the manufacturing landscape.

Core Components That Make MRP Work

A robust MRP system contains a series of components that interact to keep your production seamless:

- Inventory Management: Monitors raw materials, work in process, and finished goods to ensure there are sufficient stocks.

- Production Scheduling: Coordinates work orders with available resources and production deadlines.

- Procurement Planning: Ensures that the right material arrives at the right time from the supplier.

- Demand Forecasting: Assists in minimizing production and waste by forecasting future demand.

- Reporting and Cost Analysis: It reveals to you how good you’re doing and how much you’re spending in real time.

These elements interact to convert guesswork to fact-based decisions. You can plan confidently, reduce waste, and manage costs effectively by utilizing effective inventory optimization and forecasting.

MRP System Features That Empower Small Manufacturers

You don’t have to have a lot of money to achieve great results now. Contemporary MRP systems provide small and medium-sized manufacturers with access to solutions that were previously only within reach of large companies.

The following are things that make them so effective:

- Easy-to-read and comprehend dashboards for everyone

- You can add functionality as you expand your business since it is modular.

- Cloud access allows you to operate your business from anywhere.

- Instant reporting that provides you with data in seconds.

By integrating an MRP system with the correct warehouse management strategy, even small manufacturing plants can enjoy real-time visibility and operational clarity.

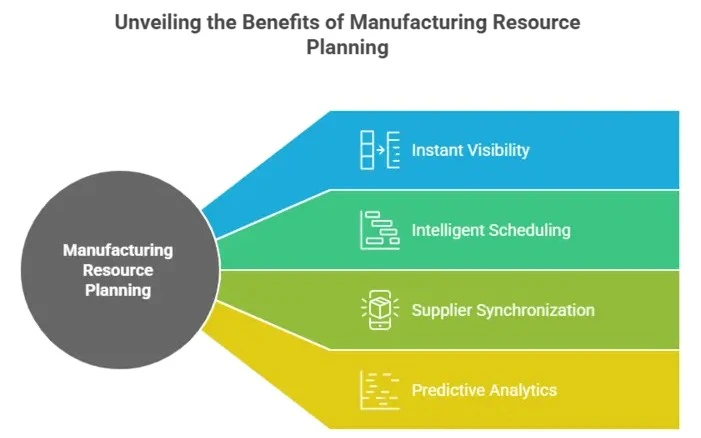

Why Manufacturing Resource Planning Reduces Lead Time

Each additional minute of production is lost revenue.

This is where manufacturing resource planning truly excels: it eliminates inefficiencies prior to creating delays.

This is how it reduces lead time

- Instant visibility: Managers see what is available and what is missing.

- Intelligent scheduling: Intelligent rescheduling stays ahead of production.

- Supplier synchronisation: Materials updates arrive just in time.

- Predictive analytics: Early indicators of potential bottlenecks.

All these capabilities transform MRP from being reactive to proactive in production.

It ensures each order is both rapid and flawless when paired with stringent quality checks in logistics.

The Cloud Advantage: MRP Without Boundaries

Ten years ago, MRP systems were limited to office servers.

Today, cloud-based MRP solutions have brought production management to the fingertips of users everywhere.

| Advantage | Why It Matters |

| Anywhere Access | Manage your plants remotely from any device |

| Cost-Effective | Pay-as-you-go pricing, no heavy infrastructure |

| Secure and Scalable | Data encryption and real-time backups |

| Integration-Ready | Connects with ERP, CRM, and IoT platforms |

These solutions are at the center of digital supply chain transformation — enabling teams to collaborate effortlessly across sites and time zones.

Open Source MRP: Intelligent, Agile, and Affordable

Open-source manufacturing resource planning software is an inexpensive means for startups and small companies to remain agile and efficient.

A few popular open-source software that is widely popular in 2025 includes

- Odoo MRP, which is open-source and modular.

- ERPNext offers plenty of features and is suitable for small manufacturers.

- Dolibarr is lightweight and suitable for basic purposes.

With open-source software, you can tailor every module to suit your requirements.

With addition of barcode scanner solution, they are more capable and transparent, so it is simpler to monitor things and ensure products can be viewed from beginning to end.

How to Install MRP Without the Agony

It doesn’t need to be complicated to install a new MRP system.

Here is a seamless, step-by-step strategy for making the transition:

- Set your goals in plain sight: Discover the issues you’re solving, such as delays, wastage, or lack of visibility.

- Set your platform: Cloud, on-premises, or open-source, depending on your size.

- Clean your data: Prior to transferring, eliminate stale and redundant records.

- Educate your staff: They are your secret to success.

- Read and refine: Leverage what you’ve learned to improve the system every day.

Firms that implement both MRP and Total Quality Management (TQM) in their supply chains tend to realize improvements in speed and accuracy within a matter of a few months.

Typical MRP Traps to Avoid

The best systems will fail if not properly configured. Avoid these typical pitfalls:

- Failing to provide users with proper training

- Trying to do too much too soon

- Failing to pay heed to data audits

- Failing to update software

Remember that success with MRP is not about complexity, but clarity. A good system should never complicate things for you.

The Future: AI Meets Manufacturing Resource Planning

The future of MRP is already here due to AI and predictive analytics.

Imagine a system that can automatically forecast demand, order materials, schedule maintenance, and avoid downtime.

That’s the future: a self-improving manufacturing ecosystem that makes decisions through data.

Manufacturing resource planning systems are becoming smarter, more connected, and more autonomous due to AI in manufacturing and real-time monitoring. This mixes automation with human wisdom.

Conclusion

Manufacturing resource planning systems are making the world a better place silently, where time, accuracy, and efficiency are the success factors.

The objective remains the same, whether it’s researching MRP system functionality for small producers, implementing a cloud-based MRP solution, or experimenting with open source MRP software: more intelligent production and accelerated growth.

By 2025 and beyond, success will not only be about what you produce, but also on how intelligently you intend to produce it.

FAQs: How MRP Systems Optimize Production Efficiency in 2025

1. What is a manufacturing resource planning system?

It is a core tool that tracks production, inventory, and scheduling to ensure manufacturing is more efficient and accurate.

2. What are the essential MRP system features for small manufacturers?

Easier-to-use dashboards, cloud-based access, and expanding modules that can adapt to the growth of your business.

3. How does manufacturing resource planning decrease lead time?

By scheduling automatically, optimizing the flow of material, and coordinating suppliers in real time.

4. Why go for a cloud manufacturing resource planning tool?

It is easy to modify, can be accessed in real-time and ramped up at a low cost.

5. Which open-source manufacturing resource planning software is dependable?

Odoo, ERPNext, and Dolibarr are all decent open-source options for small and medium-sized manufacturers.