Unlock the key to operational excellence in the cement industry with proper inventory management. This essential guide unveils cutting-edge strategies for optimising inventory processes, enhancing supply chain efficiency, and ensuring seamless operations.

Dive into proven methodologies of inventory management in the cement industry, equipping professionals with the tools needed for success. From demand forecasting to warehouse optimization, this comprehensive resource empowers industry leaders to navigate complexities and elevate their inventory management practices to new heights. This will foster sustainable growth and profitability.

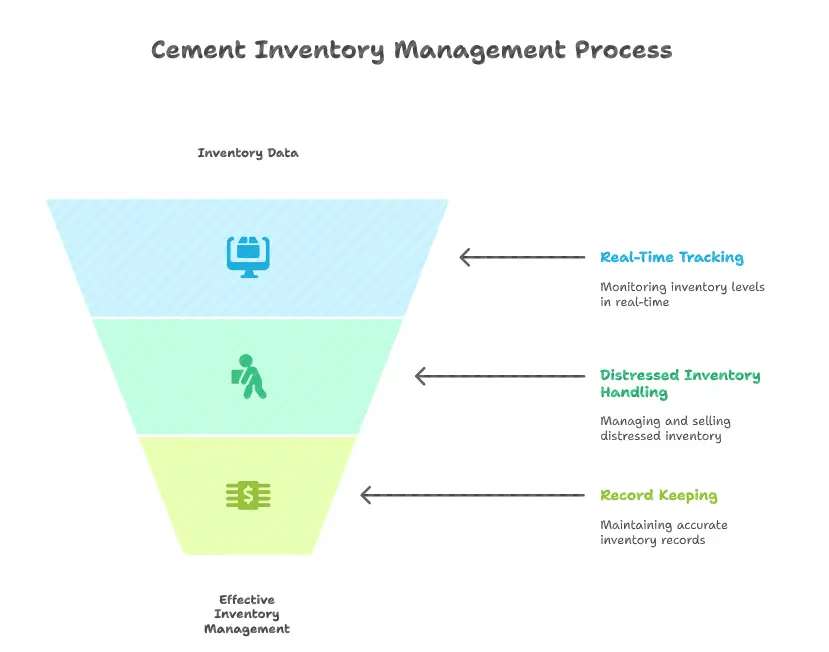

3 Strategies for Inventory Management in Cement Industry

1. Keeping Track of Inventory in Real-Time

Whеn it comеs to sеlling products and goods to customеrs, supply chain opеrations need the right amount of invеntory. For that, you nееd to adjust your invеntory accordingly. That will rеducе the risk of inventory damage or overselling.

Having thе right amount of products allows you to sеll all your products еfficiеntly. It also allows you to comparе your salеs to your compеtitors. This is thе first stеp to having a real-time insight into thе inventory lеvеls.

With inventory management in cement industry, officials would need to regularly update the inventory levels and locations in the sheet. This method works well for small companies. But what is the solution for the large ones?

The best way to ensure collaboration and real-time updates and be on track with the entire supply chain process is by viewing the inventory levels in real-time. This kind of update is possible in inventory management in the cement industry with real-time connections between warehouses and sales channels.

To ensure that this process goes smoothly and every entity in the supply chain has access to the updated inventory levels, endpoints in inventory management of cement technology are very important. Endpoints for warehouse management systems, and endpoints for sales channels, such as POS systems and online retailers need connection for seamless integration and streamlining.

2. Distressed Inventory and Overselling

You do not want your supply chain to have a distressed inventory. Distressed inventory is a well-known issue in inventory management in cement industry. This situation consists of goods that have reached the point where sellers can sell them for the normal price.

Once inventory has expired or the condition of the products deteriorates, they turn into dead inventory. This might lead to inventory loss. Companies end up discarding products and selling them at a reduced price. However, there is a solution to this when it comes to inventory management in cement industry.

It is best to keep ideal or adequate inventory levels so there is no overselling or distressed inventory. Manual calculations will not give a good idea of managing inventory levels.

However, business intelligence tools allow companies to purchase additional inventory before they run out of stock or it’s oversold. Business intelligence tools can also determine the limit purchase for certain items. For this companies and supply chains need proper inventory management.

Let’s see below how inventory management is a premium strategy for success in India cement support and resistance factors in inventory management in the cement industry.

3. Records to Ensure Effective Inventory Management

Maintaining precise records is a crucial prerequisite for effective inventory management. The absence of thorough inventory documentation poses challenges in meeting customer orders and adhering to promised shipping dates. Depending on inaccurate stock information can lead to customer dissatisfaction and a decline in business.

Whether employing software, spreadsheets, or manual techniques, the reliability of the inventory tracking system relies on accurate transaction reporting. Timely and precise reporting of inventory movements is indispensable for ensuring the dependability of the tracking system.

Automation, particularly through barcode scanning, plays a pivotal role in data collection. Numerous inventory management software options enable the generation of bar-coded lists and labels, seamlessly integrate with scanners, and streamline the data collection process.

Automated data collection not only expedites the process by eliminating the need for manual entry into inventory records but also reduces errors associated with manual procedures.

Why Inventory Management Matters in Cement Manufacturing

Cement plants must balance having enough raw materials (like limestone, gypsum, and additives) to keep production running, while avoiding excessive stock that ties up capital and storage space. Poor inventory control can lead to:

- Production delays due to stockouts

- Increased carrying costs from overstocking

- Wastage of materials due to expiry or quality deterioration

- Missed customer orders and reduced trust

The Importance of Strategic Planning

Manufacturers use Material Requirements Planning (MRP) to figure out how much and when they need each material and component, following the main production schedule.

Distributors do a similar thing called Distribution Requirement Planning (DRP). Both ways depend on predicting the requirement and then planning backwards through the distribution network (DRP) or bill of materials (MRP) to schedule orders with the latest technology in cement industries for more supplies with specific amounts and start/due dates.

The goal is to keep just enough inventory to avoid shortages, relying on accurate predictions and careful inventory tracking. Even though some businesses might have different plans that suit their markets, the main idea is the same: while keeping inventory costs money, running out of things can be bad for a company.

Simple inventory management in cement industry methods like order points might not be enough to balance having low inventory and making sure things are always available. Strong inventory management, planning, and optimization systems offer many tools to actively manage inventory in factories, warehouses, and the whole supply chain.

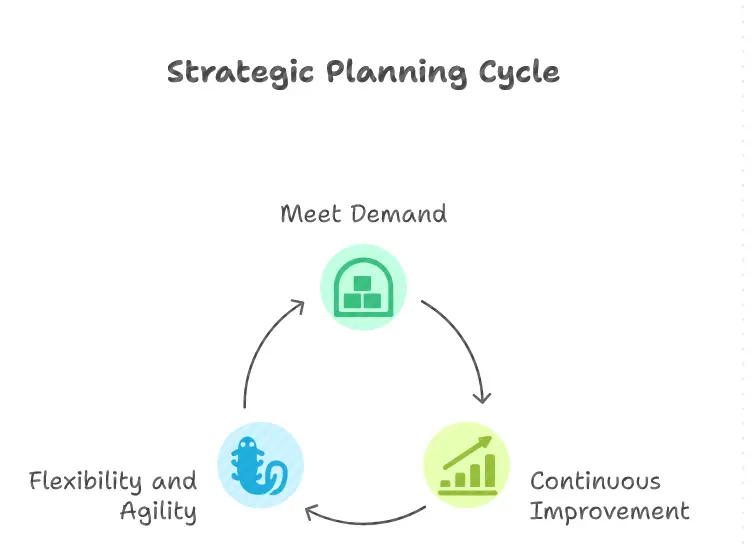

1. Meeting Demand with Appropriate Inventory Lеvеls

The first challеngе in managing your invеntory is еnsuring that itеms arе nеithеr in low stock or out of stock. It’s crucial to avoid this situation if you want your business to thrivе. In the past, companies would simply issue a backordеr whеn itеms ran out, and customers would patiеntly wait for thе product to bе rеstockеd.

Howеvеr, duе to thе sеrvicе standards sеt by major onlinе rеtailеrs, today’s consumers expect a higher level of sеrvicе. Inventory management in cement industry includes order procеssing within 24 hours, swift shipping, and affordablе, spееdy dеlivеry. Customers with thеsе expectations will not like backorders.

2. Continuous improvement and Data Analysis

Ovеrcoming challеngеs in invеntory control rеquirеs a focus on continuous improvement and data analysis. Executives should cultivate a culture of continuous improvement, encouraging stakeholders to identify areas for improvement, assess еxisting processes, and implement bеst practices.

Regularly monitoring kеy performance indicators (KPIs) rеlatеd to invеntory control, such as invеntory turnovеr, fill ratе and ordеr accuracy, allows еxеcutivеs to pinpoint areas for improvement and make decisions based on data.

Tеchniquеs of inventory management in cement industry likе trеnd analysis, root causе analysis, and predictive analytics offеr insights into dеmand pattеrns, inventory discrepancies, and supply chain bottlеnеcks.

Thеsе insights empower proactive decision-making, optimization of invеntory lеvеls, and identification of areas where efficiency gains are possible. Leveraging data analysis and continuous improvement methodologies enables manufacturing executives to enhance inventory control practices and achieve greater operational efficiency.

3. Flеxibility and Agility in the Supply Chain

Flexibility and agility arе essential strategies for overcoming invеntory control challenges, еspеcially in dynamic and volatile markеt environments. Executives should concentrate on developing a flexible and agilе supply chain capable of quickly adapting to changing customеr dеmands, markеt trеnds, and unforеsееn disruptions.

This involves dеsigning supply chain nеtworks with multiple sourcing options, implеmеnting agilе manufacturing processes, inventory management in cement industry and еstablishing contingеncy plans to mitigatе supply chain disruptions.

Embracing cement manufacturing technology like real-time inventory tracking, dеmand sеnsing, and advanced analytics provides executives with visibility into supply chain opеrations, enabling agilе decision-making based on real-time information.

By fostеring a culturе of flеxibility and agility, manufacturing еxеcutivеs can proactively respond to fluctuations in demand, minimisе еxcеss invеntory or stockouts, optimizе lеad timеs, and еnhancе ovеrall supply chain rеsiliеncе.

Conclusion

The importance of maintaining precise records, leveraging automation, and incorporating strategic planning techniques underscores the guide’s emphasis on reliability and dependability in inventory tracking.

Mastering inventory management in the cement industry requires a balanced approach—leveraging technology, forecasting demand accurately, and maintaining optimal stock levels. By applying these strategies, cement manufacturers can lower costs, improve delivery performance, and build stronger relationships with customers, ultimately driving long-term business success.

Automation, particularly through barcode scanning, expedites data collection, streamlines processes, and reduces errors associated with manual procedures in inventory management in cement industry Businesses in the cement industry allows to explore leading supply chain solutions provided by Qodenext, a trusted partner in navigating the evolving landscape of inventory management.

FAQs: Mastering Inventory Management in Cement Industry: Strategies for Success

1. How can cement companies handle the impact of seasonal demand on inventory?

Cement companies manage seasonal demand by optimising production schedules, utilising storage facilities, and implementing demand forecasting to align inventory with market fluctuations.

2. What role does technology play in modernising inventory management in the cement industry?

Technology modernises cement inventory management through automation, data analytics, and real-time monitoring, enhancing efficiency, accuracy, and responsiveness to market dynamics.

3. How can cement plants minimise the risk of supply chain disruptions affecting inventory levels?

Cement plants reduce supply chain disruption risks by diversifying suppliers, maintaining strategic stockpiles, and employing contingency plans for their modes of procurement in cement industry to ensure continuous inventory availability despite external challenges.

4. What are the key considerations in choosing inventory management software for a cement company?

Key considerations in selecting inventory management software for cement companies include scalability, integration with existing systems, real-time tracking, and customizable reporting to meet specific industry needs.

5. How can regulatory compliance be balanced with efficient inventory control in the cement sector?

Balancing regulatory compliance with efficient inventory control in the cement sector involves adopting software that ensures transparency, traceability, and real-time reporting, aligning with industry regulations without compromising operational efficiency.

6. What strategies help reduce excess inventory in cement plants?

Just-in-time (JIT) practices, accurate demand forecasting, and better coordination between production and sales help prevent overstocking.

7. How does inventory optimisation improve cost efficiency for cement companies?

Efficient inventory control reduces storage costs, minimises wastage of perishable materials (like additives), and ensures optimal use of working capital.

8. How can cement companies track raw materials and finished goods effectively?

Adopting barcode/RFID systems and warehouse management software enables precise tracking of raw materials and finished cement products across the supply chain.

9. What role does data analytics play in cement inventory management?

Data analytics helps forecast demand, identify slow-moving products, optimise reorder points, and improve overall inventory visibility.

10. How can cement companies align inventory management with sustainability goals?

By reducing overproduction, cutting down waste, optimising transport routes, and using eco-friendly storage practices, inventory management supports sustainability.