If you’ve ever lost a package or had no clue where your shipment was for days, you know the frustration that can come with logistics gone wrong.

Now imagine that happening across a global supply chain – at scale, and with millions of dollars at stake. That’s exactly why track and trace logistics has become more than important in today’s times. It’s a game-changer.

In this blog, we’re diving deep into the world of track and trace supply chain systems, how they help unlock efficiency, improve trust, and make global movement smarter.

Let’s get started.

What Is Track and Trace in Logistics?

At its core, track and trace logistics is the ability to follow the path of goods as they move from origin to destination. It allows logistics managers, partners, and even customers to know:

- Where something is

- Where it has been

- Where it’s going next

Think of it as a GPS for your products – but smarter. It doesn’t just show you a dot on a map. It connects information like time, temperature, handlers, delays, and even chain of custody.

Now that you understand the basics, let’s explore why this matters more than ever.

Why Track and Trace Is the Backbone of Modern Supply Chains

Modern supply chains are not linear. They’re complex webs involving manufacturers, warehouses, distributors, and retailers, often across continents. Without real-time logistics tracking, things fall through the cracks.

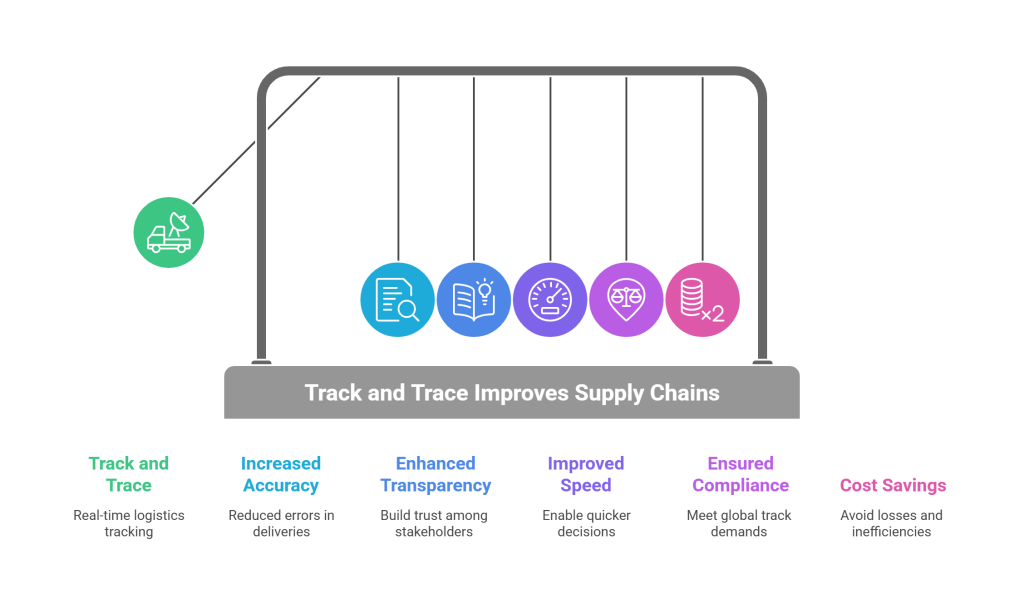

Here’s what track and trace logistics solutions bring to the table:

- Accuracy: Reduce errors in inventory and deliveries

- Transparency: Build trust among stakeholders and customers

- Speed: Enable quicker decisions through real-time data

- Compliance: Meet increasing global demands for track and trace compliance

- Cost Savings: Avoid losses due to theft, spoilage, or inefficiencies

Walmart, for instance, implemented blockchain-enabled track and trace supply chain systems to trace mangoes back to the farm in 2.2 seconds. Without it? Nearly 7 days. That speed matters when managing recalls or verifying claims.

With that context, let’s move on to some of the major components that power these systems.

What Powers Track and Trace?

Today’s track and trace logistics systems are built on an ecosystem of smart technologies. Here’s a quick look at the tech stack:

| Technology | Role in Track & Trace |

| RFID Tags | Attach to packages for real-time scanning |

| GPS | Tracks vehicle and cargo movement |

| IoT Sensors | Measure temperature, humidity, and handling |

| Cloud Platforms | Store and share data securely |

| Blockchain | Creates tamper-proof records |

| AI & ML | Predict delays, optimize routes |

For example, Pfizer uses RFID and IoT sensors in its cold chain to ensure vaccines stay within temperature thresholds – a critical track and trace compliance need in pharma.

Now that we understand the tools involved, let’s look at how companies are using them to achieve real results.

How Brands Use Track and Trace

Let’s look at how some big names are unlocking efficiency through track and trace logistics solutions:

- Maersk uses blockchain to digitize global shipping documentation, reducing paper trails and fraud.

- Zara leverages RFID to manage fast-moving fashion inventory across its stores and warehouses.

- FedEx integrates GPS and barcode systems to offer customers minute-by-minute shipment visibility.

- Nestlé implements end-to-end supply chain traceability for its baby food products to ensure safety and gain consumer trust.

What these examples show is that track and trace supply chain systems are not just about finding your shipment – they are about building smarter businesses.

So how can companies design their own track and trace strategy? Let’s explore that next.

Designing a Track and Trace Strategy That Works

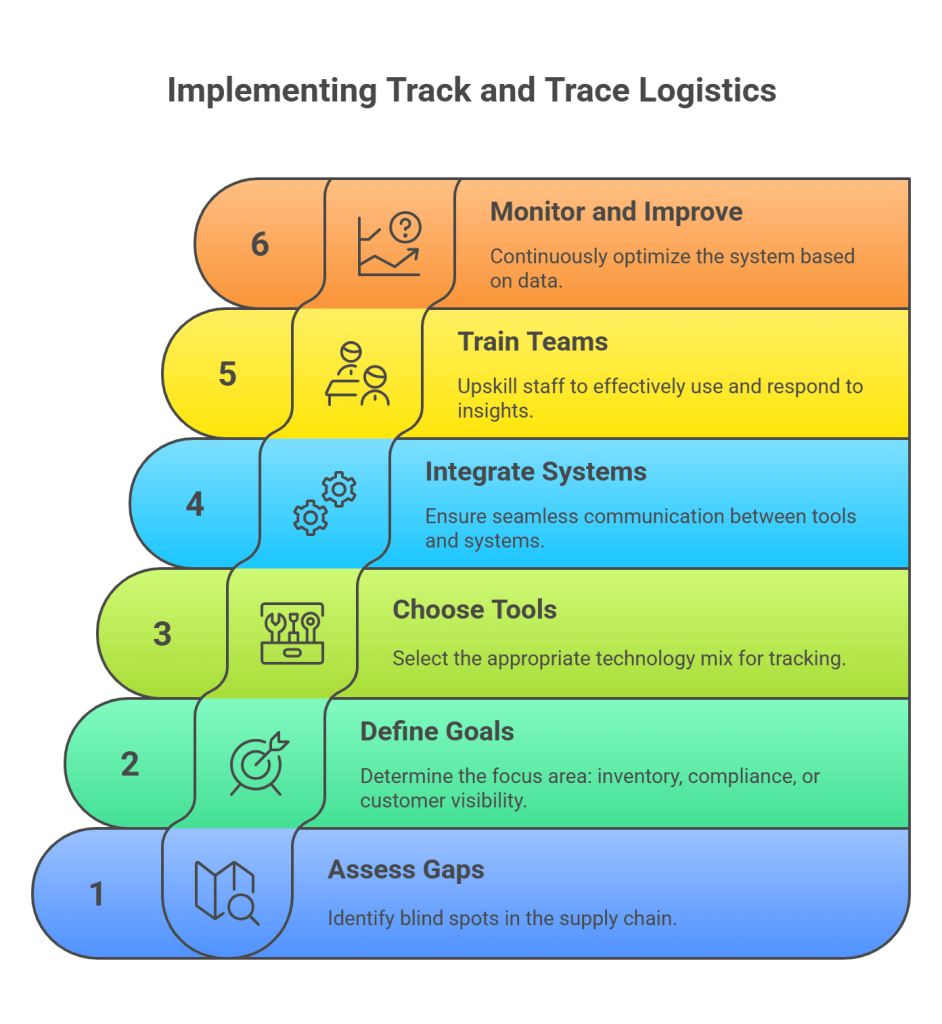

Implementing track and trace logistics isn’t a plug-and-play situation. It requires thoughtful planning. Here are the key steps:

- Assess Gaps: Identify blind spots in your supply chain.

- Define Goals: Is your focus on inventory, compliance, or customer visibility?

- Choose Tools: Select the right mix of tech (RFID, GPS, blockchain, etc.)

- Integrate Systems: Ensure tools talk to your ERP or WMS.

- Train Teams: Upskill staff to use and respond to real-time insights.

- Monitor and Improve: Continuously optimize based on data.

Tip: Start small with a high-value or high-risk segment and scale gradually.

With the strategy in place, let’s not forget one of the most critical drivers behind the adoption of track and trace: compliance.

The Rising Need for Track and Trace Compliance

Global regulations are pushing companies to embrace track and trace compliance like never before. Industries like pharmaceuticals, food & beverage, and automotive are seeing the biggest impact.

Here are some compliance examples:

- DSCSA (US): Requires pharma companies to trace medications across the supply chain

- EU FMD: Mandates serialization of medical products

- FSMA (Food Safety Modernization Act): Demands food traceability to prevent outbreaks

Ignoring these can lead to recalls, fines, and damaged reputation. That’s why track and trace logistics is no longer optional – it’s foundational.

Since compliance is key, let’s now look at the benefits from a value-creation perspective.

Benefits That Go Beyond Visibility

While visibility is the headline act, the supporting cast of benefits from track and trace logistics solutions is just as impressive:

- Improved Forecasting: Real-time data feeds help AI-driven planning

- Customer Experience: Fewer missed deliveries or surprise delays

- Sustainability: Reduces waste and optimizes transportation

- Risk Mitigation: Identifies disruptions faster

Amazon is a great example. It combines real-time logistics tracking with predictive analytics to reroute packages mid-journey during delays.

Knowing the benefits, how do you decide which system to invest in?

Choosing the Right Track and Trace Solution

There are plenty of providers, but not all fit every business. Here’s how to choose a track and trace logistics solution that fits:

| Feature | Why It Matters |

| Scalability | Grows with your business |

| Integration | Works with existing platforms |

| Customization | Meets industry-specific needs |

| Data Security | Ensures compliance and privacy |

| User Interface | Easy for teams to adopt |

Evaluate not just tech specs but also vendor support, implementation timelines, and long-term value.

FAQs: How Track and Trace Is Powering the Next-Gen Logistics Revolution

1: How does track and trace improve inventory management?

It helps reduce stockouts and overstocks by giving real-time visibility into product location and movement, improving forecasting.

2: Is blockchain necessary for track and trace?

Not always. Blockchain adds security and transparency but smaller businesses can start with RFID and cloud tracking systems.

3: Can track and trace be used in last-mile delivery?

Absolutely. It’s especially useful for urban logistics, food delivery, and e-commerce, improving customer satisfaction.

4: What’s the cost range for implementing a system?

It depends on scale. Small businesses may spend a few thousand dollars, while enterprise-level systems could reach six figures.

5: Are there any open-source track and trace tools?

Yes, some platforms like Hyperledger offer open-source blockchain frameworks for developing traceability solutions.

6. Can track and trace solutions help prevent counterfeiting and theft?

Yes. By providing real-time tracking and chain of custody records, track and trace systems deter theft and make it easier to spot and remove counterfeit products, especially in sensitive industries like pharmaceuticals and electronics.

7. How does track and trace support sustainability goals?

Track and trace solutions help optimize routes, reduce fuel consumption, minimize packaging waste, and quickly identify lost or spoiled goods—supporting eco-friendly supply chain practices and reducing environmental impact.

8. What industries benefit most from track and trace logistics?

Sectors including pharmaceuticals, food and beverage, automotive, fashion, logistics, and electronics see significant gains from improved visibility, compliance, and recall management enabled by track and trace systems.

9. What data is typically captured in a track and trace system?

Beyond location, these systems record timestamps, temperature/humidity, handlers, chain of custody, transit delays, and sometimes regulatory details, creating a comprehensive audit trail for each item.

Conclusion

Track and trace logistics is more than just about watching your goods move. It’s a strategic investment in visibility, agility, compliance, and customer trust. Whether it’s ensuring cold chain compliance in pharma or optimizing shelf replenishment in retail, track and trace supply chain systems offer real-time answers in a world that can’t afford uncertainty.

The brands leading the charge are those treating supply chain traceability not as a cost but as a catalyst for transformation. The question now is: where does your organization stand?