Procurement may seem like a back-office task, but it plays a central role in a company’s performance.

From sourcing raw materials to managing suppliers, the procurement process directly impacts cost, delivery timelines, and customer satisfaction. But traditional procurement systems often struggle with one thing: visibility.

That’s where RFID (Radio Frequency Identification) tagging comes in. By using RFID technology in vendor processes, businesses can automate tracking, reduce manual errors, and boost overall procurement efficiency.

In this blog, we’ll explore how RFID tagging is helping organizations simplify their procurement workflows, strengthen vendor management, and future-proof their operations.

Understanding RFID Tagging in Procurement

RFID technology uses radio waves to automatically identify and track tags attached to objects. In procurement, these tags are typically applied at the supplier’s end (vendor tagging), ensuring that each shipment can be tracked in real-time, from dispatch to delivery.

Compared to barcodes, RFID tags don’t need line-of-sight scanning. They can be read remotely and in bulk, making them ideal for fast-paced environments like warehouses or inbound receiving docks.

Walmart, for example, has implemented RFID tagging across its supply chain to improve stock accuracy by over 95%, reduce out-of-stock incidents, and streamline replenishment cycles.

Now that we understand the basics, let’s look at how RFID enhances the procurement lifecycle.

Real-Time Visibility from Source to Shelf

One of the biggest barriers to procurement efficiency is a lack of visibility into shipment status. Delays at a vendor’s facility often go unnoticed until it’s too late.

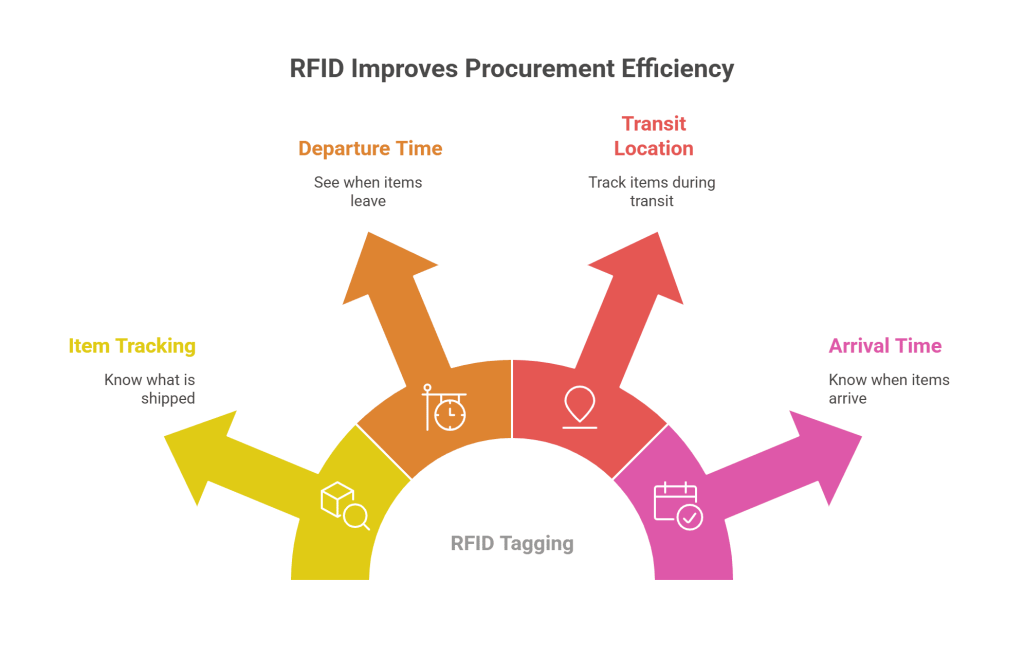

With vendor RFID tagging, companies gain real-time updates on:

- What items are being shipped

- When they leave the supplier’s warehouse

- Where they are during transit

- When they arrive at the receiving dock

This enhanced visibility reduces guesswork and improves decision-making across the procurement process.

Let’s move from visibility to another major benefit: accuracy.

Increased Accuracy, Less Manual Intervention

Procurement errors like miscounts, mismatched SKUs, or missed deliveries, often stem from manual data entry. RFID tagging automates item identification, reducing reliance on human intervention.

For instance, Decathlon, the global sports retailer, uses RFID to automate inventory checks and receiving processes. This has helped the brand cut receiving time by up to 90% in some warehouses.

Automating item verification at the receiving end ensures that procurement teams spend less time reconciling discrepancies and more time optimizing workflows.

Now that we’ve seen how RFID improves accuracy, let’s talk about its role in vendor management.

Strengthening Vendor Relationships Through Data

Good vendor management is rooted in trust and performance tracking. RFID tagging enables better monitoring of vendor performance through data like:

- On-time delivery rates

- Accuracy of shipped goods

- Frequency of delivery errors

With this data, procurement managers can:

- Reward top-performing vendors

- Set benchmarks for new suppliers

- Trigger alerts for underperforming partners

This creates transparency and shared accountability. For example, Boeing integrates RFID-based vendor tracking with its procurement system to better coordinate with global parts suppliers, reducing project delays in aircraft assembly.

Now that vendor relationships are better informed, let’s see how RFID impacts the speed of the procurement process.

Faster Receiving and Quality Checks

Traditional receiving and inspection processes can be time-consuming, especially when done manually.

RFID-tagged shipments allow warehouses to:

- Instantly scan all items in a pallet or container

- Trigger automated quality check workflows

- Match incoming inventory with purchase orders

This means faster turnaround times, fewer bottlenecks, and better alignment between procurement and warehouse teams.

For large manufacturers like Unilever, integrating RFID-tagged procurement data with warehouse systems helps speed up inbound logistics and reduce cycle times.

Next, let’s look at the cost implications.

Cost Savings Through Error Reduction and Optimization

While there is an upfront investment in RFID infrastructure, the long-term savings are significant:

- Fewer returns due to mis-shipments

- Less labor spent on manual tracking

- Reduced losses from lost or misplaced inventory

According to a report by McKinsey, companies using RFID in procurement and logistics can reduce operational costs by up to 15% through improved accuracy and labor efficiency.

That brings us to another advantage: integration with existing systems.

Seamless Integration with ERP and Procurement Tools

The real power of RFID comes when it’s integrated with your ERP or procurement platform. Tag scans can trigger:

- Automatic goods receipt confirmations

- Real-time inventory updates

- Payment approvals based on receipt status

Platforms like SAP Ariba and Oracle SCM Cloud offer built-in support for RFID-driven workflows.

This integration ensures that procurement efficiency isn’t just about the warehouse but the entire supply chain – from order placement to invoice reconciliation.

Let’s now consider future trends that are building on this RFID foundation.

The Future: AI, IoT, and Blockchain

RFID is not evolving in isolation. When combined with technologies like:

- AI (for anomaly detection and predictive procurement)

- IoT (for sensor-driven logistics)

- Blockchain (for tamper-proof tracking)

the procurement ecosystem becomes smarter and more secure.

Retailers like Zara are already leveraging RFID + AI to predict purchasing trends and automate restocking based on real-time sales and stock levels.

FAQs: How RFID Tagging is Simplifying Procurement Efficiency

1. Is RFID suitable for small businesses?

Yes. With falling hardware costs and SaaS-based RFID platforms, even SMBs can implement RFID for selective procurement use cases.

2. Can RFID be used for all types of inventory?

Mostly yes. However, metal and liquids can interfere with radio signals. Specialized RFID tags are available to overcome this.

3. What’s the ROI on RFID in procurement?

Depends on volume and complexity. Businesses typically see ROI within 12–18 months due to labor savings and error reduction.

4. How secure is RFID data?

Modern RFID systems use encrypted communication and can be secured via access control layers and ERP-level authentication.

5. Is RFID better than barcodes?

For bulk, high-speed, or remote scanning needs, yes. But for low-volume use cases, barcodes remain cost-effective.

Conclusion

RFID vendor tagging is more than a technology – it’s a strategy.

It helps unlock greater visibility, fewer errors, smarter vendor management, and faster decision-making.

In a landscape where procurement efficiency can make or break business operations, RFID is proving to be a silent powerhouse.If you’re looking to scale your procurement operations, it’s time to consider tagging your strategy with RFID.