Fleet idle time can be a significant source of inefficiency in manufacturing facilities. When trucks, forklifts, and other vehicles are not actively engaged in transporting goods or materials, they are essentially wasting resources and adding unnecessary costs. Not only does idle time increase fuel consumption and maintenance costs, but it can also lead to delays in production and shipping schedules. To address this issue, there are several strategies that companies can implement to reduce fleet idle time, going as fleet management and improving overall operational efficiency.

In this blog, we will explore some of the most effective methods for minimizing idle time and maximizing productivity in your factory.

Vehicle Tracking System for Fleet Management

A vehicle tracking system is an essential tool for fleet management, enabling businesses to monitor their vehicles’ locations, movements, and performance in real time. Here are five benefits of using a vehicle tracking system:

- Improved efficiency: With a vehicle tracking system, fleet managers can optimize routes, reduce idle time, and manage fuel consumption, resulting in increased operational efficiency.

- Enhanced safety: Vehicle tracking systems can alert fleet managers to unsafe driving behavior, such as speeding and harsh braking, and help prevent accidents before they occur.

- Better customer service: Real-time vehicle tracking enables businesses to provide accurate delivery estimates to customers and respond quickly to any delays or issues that may arise.

- Cost savings: By reducing fuel consumption, maintenance costs, and the risk of theft or misuse, vehicle tracking systems can help businesses save money and increase profitability.

- Regulatory compliance: Vehicle tracking systems can help businesses comply with industry regulations, such as the hours-of-service rules for commercial drivers, and provide evidence of compliance in case of audits or inspections

Is Fleet Management a Good Company?

It is difficult to make a definitive statement about whether fleet management is a good company, as many factors can influence one’s perception of a company’s quality.

However, some general factors that can be considered when evaluating a company include its reputation, financial stability, employee satisfaction, and overall impact on society and the environment.

To assess the reputation of a company, it is helpful to look at reviews from customers, employees, and industry experts. Financial stability can be evaluated by examining the company’s financial reports and assessing its ability to weather economic downturns.

Employee satisfaction can be evaluated through surveys and reviews on websites like Glassdoor. Finally, the company’s impact on society and the environment can be evaluated by looking at its sustainability practices, social responsibility initiatives, and compliance with relevant laws and regulations.

With regards to fleet management specifically, it is important to note that many different companies fall under this umbrella term. Some fleet management companies specialize in specific industries, such as trucking or logistics, while others may offer more general services.

The quality of a particular fleet management company will depend on factors like its size, expertise, customer service, and pricing structure.

Overall, it is difficult to make a blanket statement about whether fleet management is a good company without evaluating specific companies within the industry.

However, by considering factors like reputation, financial stability, employee satisfaction, and social and environmental impact, one can gain a better understanding of the quality of a particular fleet management company.

IoT for Fleet Management

IoT (Internet of Things) technology has revolutionized the way we manage fleets, providing businesses with valuable insights into the performance and status of their vehicles and assets.

By utilizing IoT devices, companies can effectively monitor and manage their fleets, improve operational efficiency, and reduce costs. Here are some of the key benefits of using IoT for fleet management:

1. Real-time tracking and monitoring:

IoT sensors and devices can provide real-time location tracking, vehicle diagnostics, and driver behavior monitoring, allowing businesses to quickly identify issues and take action to optimize performance.

2. Predictive maintenance in fleet management:

IoT sensors can monitor vehicle performance and identify potential maintenance issues before they become major problems, reducing downtime and maintenance costs.

3. Improved safety and security:

IoT devices can monitor driver behavior, detect accidents and provide alerts in real-time, enabling companies to take swift action to ensure the safety of their drivers and vehicles.

4. Increased efficiency:

IoT technology can provide valuable data insights, helping companies optimize routes, reduce fuel consumption, and improve overall operational efficiency.

5. Enhanced customer service in fleet management:

Real-time tracking and monitoring capabilities enable businesses to provide more accurate delivery estimates to customers and improve customer service overall.

Overall, IoT technology offers significant benefits for fleet management, providing businesses with the data insights and real-time monitoring capabilities they need to optimize their operations and reduce costs.

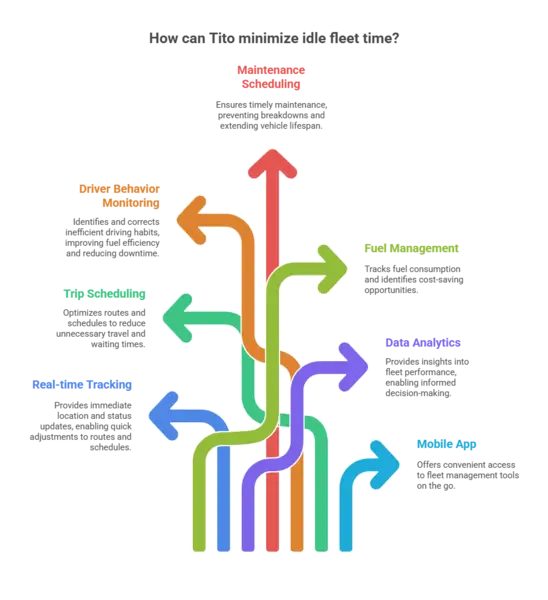

How Tito (Truck in Truck Out) From Qodenext Can Help in Minimizing Idle Fleet Time?

Qodenext’s Tito is a fleet management software that can help reduce idle fleet time by providing several features and benefits. Here are seven ways Tito can help in reducing idle fleet time:

• Real-time tracking: Tito provides real-time GPS tracking of vehicles, which enables fleet managers to monitor the location and movement of their vehicles at all times. This can help them identify idle vehicles and take necessary actions to reduce idle time.

• Trip scheduling: Tito allows fleet managers to schedule trips for their vehicles in advance. This can help them optimize their routes and reduce idle time between trips.

• Driver behavior monitoring: Tito can monitor driver behavior, such as excessive idling or speeding, and provide alerts to fleet managers. This can help them take corrective actions and reduce idle time.

• Maintenance scheduling: Tito can help fleet managers schedule regular maintenance for their vehicles. This can help prevent breakdowns and reduce idle time due to maintenance issues.

• Fuel management: Tito can monitor fuel consumption and identify vehicles with high fuel consumption. This can help fleet managers take necessary actions, such as replacing inefficient vehicles or implementing fuel-saving measures, to reduce idle time.

• Data analytics: Tito can provide data analytics and insights on fleet performance, including idle time. This can help fleet managers identify patterns and trends and take necessary actions to reduce idle time.

• Mobile app: Tito has a mobile app that enables drivers to communicate with fleet managers in real-time. This can help fleet managers track and manage their vehicles more efficiently and reduce idle time.

Fleet Tracking GPS: Advanced Vehicle Management Solutions

A fleet tracking GPS allows real-time vehicle tracking for corporations. Advanced fleet tracking solutions offer precise location information and driver behavior analysis. Organizations utilizing GPS fleet management save on fuel expenses and enhance route optimization.

Fleet tracking systems provide complete dashboards for fleet management. Fleet tracking systems incorporate maintenance notifications and geofencing features. Advanced GPS fleet management solutions offer analytics for decision-making.

Fleet monitoring systems provide added security with real-time theft alerts. Companies enjoy operational clarity with fleet tracking GPS technology. The integration simplifies logistics, enhances productivity, and guarantees regulatory compliance. Smart fleet management redefines transportation operations efficiently.

Conclusion

In conclusion, reducing fleet idle time can have a significant impact on your factory’s overall productivity and profitability. Implementing a comprehensive fleet management system can help you identify areas where idle time can be reduced, such as route optimization and driver behavior monitoring.

By implementing such a system, you can save costs and improve efficiency in your factory’s fleet operations. Don’t hesitate to explore the benefits of fleet management for your factory today and consider investing in a reliable solution to streamline your processes. Start reducing idle time and increase your factory’s overall productivity today with QodeNext.

Frequently Asked Questions (FAQs) :

1. What is the best strategy for reducing idling time?

Smooth work processes and equal distribution of work. Make use of schedule tasks as a way of reducing activity gaps.

2. How can idle time be reduced in fleet management?

– Enhance planning and scheduling.

– Flexible training of workers.

– Keep the equipment in a good condition.

– Optimize material flow

– Utilize real time monitoring systems.

3. Which of the following is a method of reducing idle time?

Prevention maintenance, improved production scheduling, multi-skilling of the workers, invention management and automation

4. What are the reasons for booking workers on idle time in a factory?

To monitor the loss of productivity, estimate actual labor expenses, uncover the inefficiencies, adhere to the accounting standards, and organize the improvements.

5. What sensor can cause high idle?

Erratic idling can be as a result of faulty throttle position sensor, mass airflow sensor, idle air control valve, or oxygen sensor.

6. Why does RPM increase in idle?

Engine accommodates additional load of AC, alternator or power steering. ECU compensates temperature or vacuum leakages.

7. How to fix idling problem?

Check, clean throttle body, vacuum leaks, change air filter, test sensor, adjust idle speed screw, or ECU software.