The automotive industry is undergoing a revolutionary shift, thanks to the widespread integration of automation technology. Automation is reshaping the way vehicles are designed, manufactured, and utilized. From autonomous vehicles and intelligent assembly lines to advanced driver-assistance systems, automation is rapidly transforming the automotive landscape.

This blog explores the profound impact of automation on the industry, unveiling its potential to enhance efficiency, safety, and overall mobility. Join us as we embark on a captivating journey into the future of the automotive industry, where automation plays a pivotal role in shaping an innovative and interconnected world of transportation.

What Is Automation in Automotive Industry?

Automation in the automotive industry refers to the integration of advanced technologies and systems to perform various tasks and functions that were traditionally carried out by human operators. It involves the use of robotics, artificial intelligence, and computerized systems to streamline and optimize processes in manufacturing, assembly, testing, and logistics within the automotive production cycle. Key features of automation in the automotive industry include:

- Robotic Assembly: In automated assembly processes, robotic arms are programmed to perform intricate tasks with high precision. These tasks may include welding, painting, and attaching components. Robotic assembly offers several advantages, such as increased speed, improved accuracy, and the ability to handle repetitive tasks without fatigue. It also reduces the risk of human error and enhances overall productivity.

- Material Handling: Automation in material handling involves the use of automated guided vehicles (AGVs), conveyors, and robotic systems to transport materials and components within the production facility. AGVs are self-driving vehicles that can navigate predefined paths and carry loads, while conveyors efficiently move materials from one point to another. These automated systems reduce the reliance on manual labor, minimize the risk of accidents, and optimize the flow of materials, resulting in improved efficiency and throughput.

- Quality Control: Automated inspection systems play a crucial role in maintaining consistent product quality. These systems utilize sensors, cameras, and advanced algorithms to inspect components, detect defects, and measure tolerances. By automating quality control processes, manufacturers can ensure that every product meets the required standards, reducing the risk of faulty or subpar vehicles reaching the market.

- Data Analytics: Automation generates a vast amount of data throughout the automotive production cycle. This data can be harnessed through analytics tools and algorithms to gain valuable insights and drive improvements. Manufacturers can analyze production data to identify bottlenecks, optimize processes, and reduce waste. Furthermore, data analytics can be used for predictive maintenance, enabling proactive identification of potential equipment failures and scheduling maintenance before breakdowns occur, thereby minimizing downtime.

- Supply Chain Management: Automation is instrumental in streamlining supply chain management in the automotive industry. Manufacturers can utilize automated systems for inventory management, tracking, and coordination with suppliers, as well as for monitoring and optimizing logistics operations. This automation improves the accuracy of inventory records, ensures the timely delivery of components, and facilitates efficient collaboration among different stakeholders in the supply chain.

- Driver Assistance Systems: Automation extends to the vehicles themselves through the integration of advanced driver assistance systems (ADAS). ADAS incorporates technologies such as sensors, cameras, and radar to enable features like autonomous braking, adaptive cruise control, and lane-keeping assistance. These systems assist drivers in various scenarios, enhancing safety, reducing driver fatigue, and improving the overall driving experience.

In summary, automation in the automotive industry revolutionizes production, quality control, and supply chain management by leveraging robotics, data analytics, and advanced technologies. It optimizes processes, improves efficiency, reduces errors, and enhances safety, ultimately benefiting both manufacturers and consumers alike.

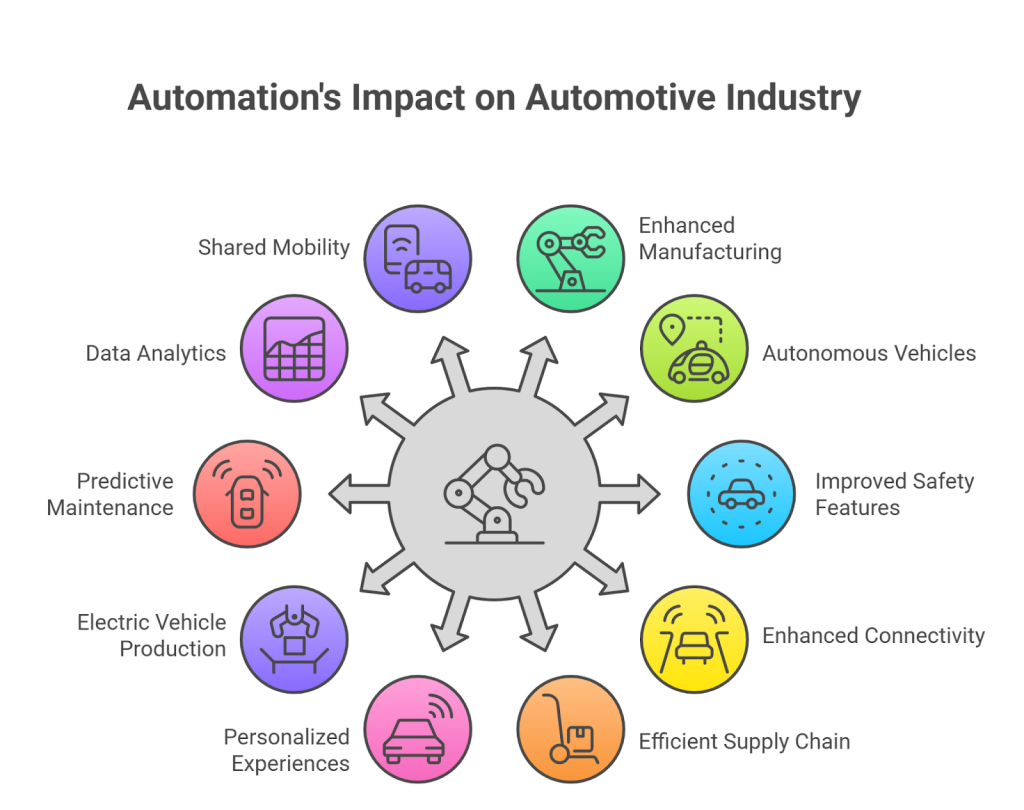

Ways in Which Automation Is Impacting the Future of Automotive Industry

Automation is revolutionizing the automotive industry, bringing about significant transformations. Here are six ways in which automation is impacting its future:

Enhanced Manufacturing Processes

Automation enables streamlined and efficient manufacturing, with robots performing tasks such as welding, assembly, and painting, leading to increased production speed and precision.

- Autonomous Vehicles: Automation is driving the development of self-driving vehicles, which have the potential to transform transportation by improving road safety, reducing traffic congestion, and enhancing mobility for all.

- Improved Safety Features: Automation facilitates the integration of advanced driver assistance systems (ADAS) in vehicles, including features like adaptive cruise control, lane-keeping assist, and automatic emergency braking, enhancing overall safety on the roads.

- Enhanced Vehicle Connectivity: Automation is enabling increased connectivity in cars, allowing for features such as GPS navigation, real-time traffic updates, and remote vehicle monitoring, enhancing the overall driving experience.

- Efficient Supply Chain Management: Automation is optimizing supply chain processes in the automotive industry, enabling better inventory management, predictive maintenance, and streamlined logistics, leading to cost savings and improved efficiency.

- Personalized Customer Experiences: Automation enables personalized customer experiences through technologies like voice assistants, smart infotainment systems, and advanced driver customization options, enhancing overall comfort and convenience.

- Electric Vehicle (EV) Production: Automation plays a crucial role in the manufacturing of electric vehicles, from battery production to assembly lines, contributing to increased production efficiency and scalability of EVs.

- Predictive Maintenance: Automation allows vehicles to monitor their own performance and detect potential issues in real time, enabling proactive maintenance and reducing downtime for repairs, thereby increasing overall vehicle reliability.

- Data Analytics and Machine Learning: Automation enables the collection and analysis of vast amounts of data generated by vehicles, leading to insights that can enhance vehicle performance, optimize fuel efficiency, and enable predictive analytics for future developments.

- Shared Mobility and Ride-Hailing: Automation is driving the growth of shared mobility and ride-hailing services by enabling autonomous vehicles to be deployed as a cost-effective and convenient alternative to traditional transportation methods.

These advancements in automation are reshaping the automotive industry and paving the way for a future of increased efficiency, safety, and sustainability.

Applications of Automation in Automotive Industry

Automation has revolutionized the automotive industry, enhancing efficiency and productivity. Here are five notable applications of automation in this sector:

- Manufacturing and Assembly: Robotic arms and automated systems are used for precise and rapid assembly of components, reducing human labor and increasing production speed. Automated guided vehicles (AGVs) transport materials and parts within factories, optimizing logistics and minimizing manual handling.

- Quality Control: Automated vision systems and machine learning algorithms are employed to inspect components, ensuring high levels of accuracy and reducing human error. Robotic arms equipped with sensors perform repetitive and precise measurements, guaranteeing consistency and reliability.

- Material Handling: Automated conveyor systems efficiently move raw materials, parts, and finished products throughout the production line, eliminating manual handling and reducing the risk of damage or injury. Autonomous mobile robots (AMRs) navigate warehouses and distribution centers, streamlining inventory management and order fulfillment.

- Testing and Validation: Automation plays a crucial role in various testing processes, including crash tests, emissions testing, and durability evaluations, enhancing accuracy and replicability. Autonomous test vehicles equipped with sensors and data collection systems enable real-world testing scenarios, accelerating the development and validation of new technologies.

- Supply Chain Management: Automation is employed in tracking and monitoring inventory levels, optimizing order management, and facilitating seamless coordination between suppliers, manufacturers, and distributors. Predictive analytics and AI algorithms help forecast demand, optimize production schedules, and improve overall supply chain efficiency.

These applications demonstrate how automation has transformed the automotive industry, enabling increased productivity, improved quality control, enhanced safety, and streamlined operations throughout the entire value chain.

Conclusion

In conclusion, we can say that automation is revolutionizing the automotive industry, ushering in a new era of efficiency, safety, and convenience. With advancements in autonomous vehicles, smart manufacturing processes, and intelligent systems, automation is reshaping the future of transportation.

Qodenext, a leading technology provider, offers cutting-edge solutions and expertise to help automotive companies navigate this transformative landscape. Contact Qodenext today to leverage automation and stay ahead in the rapidly evolving automotive industry.

FAQ on How Automation Is Impacting the Future of Automotive Industry?

1. What does automation mean in the automotive industry?

Automation in the automotive industry refers to using robotics, AI, and smart systems to streamline manufacturing, assembly, quality control, and supply chain operations.

2. How is automation changing vehicle manufacturing?

Automation enhances production with robotic assembly, automated material handling, and intelligent quality control, leading to faster, safer, and more precise manufacturing.

3. What role do autonomous vehicles play in automation?

Autonomous vehicles represent a key outcome of automation, aiming to improve road safety, reduce traffic congestion, and transform mobility.

4. How does automation improve safety in vehicles?

Through advanced driver-assistance systems (ADAS) like lane-keeping assist, adaptive cruise control, and automatic braking, automation boosts driver and passenger safety.

5. Can automation improve supply chain management in the automotive sector?

Yes, automation helps track inventory, streamline logistics, enable predictive maintenance, and optimize supplier coordination for greater efficiency.

6. What is the impact of automation on quality control?

Automated inspection systems with sensors and AI detect defects early, ensuring high-quality standards and reducing faulty vehicles in the market.

7. How does automation support electric vehicle (EV) production?

Automation optimizes EV battery manufacturing, assembly lines, and scalability, making electric vehicle production more efficient and cost-effective.

8. What role does data analytics play in automotive automation?

Automation generates valuable production and vehicle data, which can be analyzed to improve processes, predict failures, and enhance vehicle performance.

9. How does automation personalize customer experiences?

Technologies like smart infotainment, voice assistants, and driver customization options allow more tailored and convenient driving experiences.

10. Why is automation essential for the future of the automotive industry?

Automation drives efficiency, safety, sustainability, and innovation, making it crucial for automakers to remain competitive in 2025 and beyond.