In the rapidly evolving landscape of supply chain management, excess inventory stands as a formidable challenge for businesses. As we step into 2024, it’s imperative to comprehend the dynamic technology trends shaping the industry. This article will explore the top supply chain technology trends while focusing on the critical issue of excess inventory. From understanding the concept and its repercussions to implementing cutting-edge solutions, we’ll delve into preventive strategies, management techniques, and innovative approaches to selling surplus stock. Emphasizing the pivotal role of technology, we’ll highlight Qodenext’s contribution to revolutionizing excess inventory solutions for businesses.

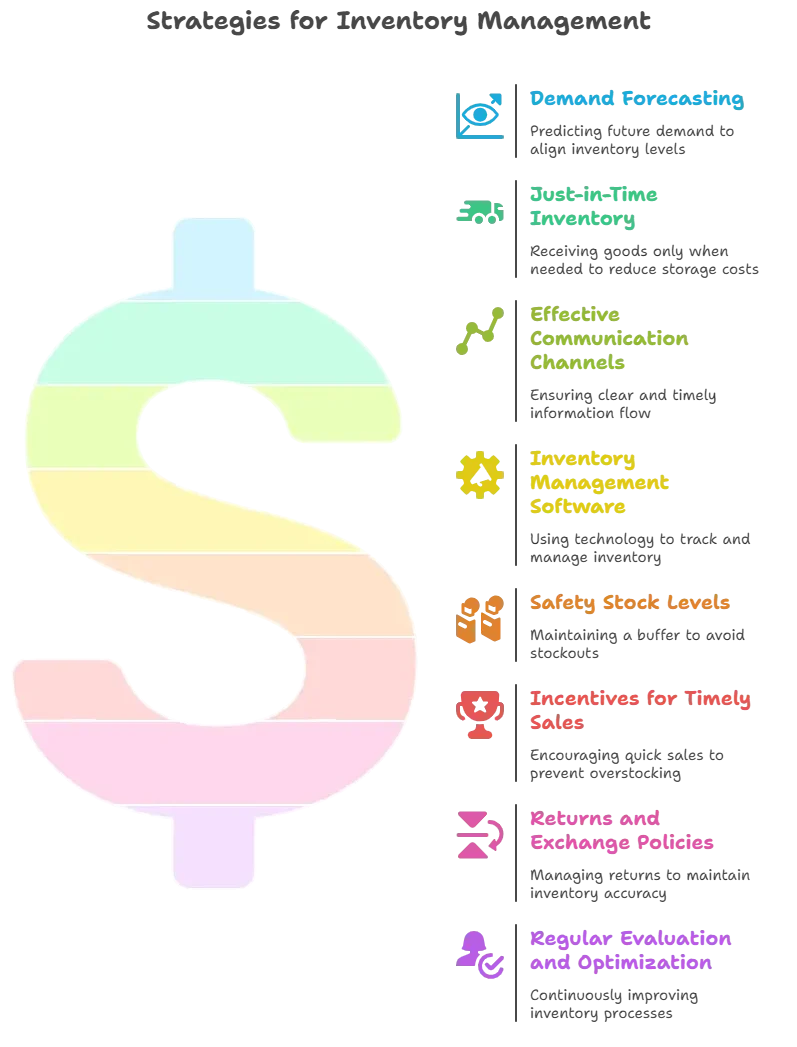

How To Prevent Excess Inventory

Excess inventory can pose significant challenges for businesses, tying up capital and warehouse space while increasing the risk of product obsolescence. To maintain a healthy balance between supply and demand, it’s crucial to implement effective strategies to prevent excess inventory. In this guide, we will explore key pointers on how businesses can successfully manage their inventory levels.

1. Demand Forecasting:

Accurate demand forecasting is the cornerstone of inventory management. By leveraging historical data, market trends, and customer behavior, businesses can develop precise predictions of future demand. Regularly update and refine forecasting models to adapt to changing market conditions, ensuring inventory levels align with actual consumer needs.

2. Just-in-Time Inventory:

Implementing a just-in-time (JIT) inventory system allows businesses to receive goods only as they are needed for production or to meet customer demand. This approach minimizes the need for excessive storage space and reduces the risk of overstocking. However, it requires a robust supply chain and reliable suppliers to function effectively.

3. Establish Effective Communication Channels:

Maintain open lines of communication with suppliers, distributors, and other stakeholders in the supply chain. Regularly share sales forecasts, product updates, and other relevant information to ensure everyone is on the same page. This collaborative approach helps prevent misunderstandings and minimizes the risk of excess inventory due to miscommunication.

4. Utilize Inventory Management Software:

Invest in advanced inventory management software to streamline the tracking and control of stock levels. These tools can automate reorder processes, monitor sales patterns, and provide real-time insights into inventory performance. Leveraging technology ensures a more proactive and responsive approach to inventory management.

5. Monitor and Adjust Safety Stock Levels:

While safety stock is essential to buffer against unforeseen fluctuations in demand or supply chain disruptions, it’s crucial to monitor and adjust these levels regularly. Periodically reassess your safety stock policies based on historical data and market dynamics to prevent unnecessary accumulation of excess inventory.

6. Offer Incentives for Timely Sales:

Encourage timely sales by implementing promotions, discounts, or limited-time offers. This strategy not only stimulates customer demand but also helps to clear out excess inventory. By creating a sense of urgency, businesses can motivate customers to make purchases, reducing the risk of overstock situations.

7. Implement Returns and Exchange Policies:

Establish clear and customer-friendly returns and exchange policies to manage inventory effectively. This not only improves customer satisfaction but also facilitates the timely return of unsold products, preventing them from becoming excess inventory.

8. Regularly Evaluate and Optimize:

Continuously evaluate your inventory management processes and performance. Regularly analyze sales data, customer feedback, and market trends to identify areas for improvement. Optimize your strategies based on these insights, ensuring a dynamic and adaptable approach to preventing excess inventory.

Effectively managing inventory levels requires a proactive and strategic approach. By incorporating demand forecasting, JIT inventory systems, communication, technology, and other key strategies, businesses can minimize the risk of excess inventory, optimize warehouse space, and enhance overall operational efficiency.

What Are The Effects Of Excess Inventory

Excess inventory, when not managed effectively, can have detrimental effects on businesses across various industries. This surplus of goods often leads to a cascade of challenges that can impact financial health, operational efficiency, and customer satisfaction. In this article, we will delve into the repercussions of having an abundance of inventory and explore strategies to mitigate these issues.

Financial Strain:

One of the foremost effects of excess inventory is the financial strain it places on a business. Capital tied up in unsold stock represents a missed opportunity for investment in more profitable areas of the company. The cost of holding excess inventory includes warehousing expenses, increased insurance costs, and potential losses due to obsolescence.

Reduced Profit Margins:

As inventory accumulates, businesses often resort to discounting to move products quickly. This compromises profit margins and can create a domino effect, especially in industries with intense competition. Frequent promotions to clear excess stock can lead to a perception of lower product value, impacting long-term profitability.

Operational Inefficiencies:

Excessive inventory can disrupt the operational flow of a business. Warehouses may become overcrowded, making it challenging to locate and manage products efficiently. This can result in increased handling costs, longer order fulfillment times, and a higher likelihood of errors in inventory management.

Obsolescence and Depreciation:

Technology evolves rapidly, and consumer preferences change. Excess inventory is susceptible to obsolescence, particularly in industries where products have a short shelf life. Businesses must grapple with the challenge of managing depreciating assets, which can lead to substantial financial losses.

Supply Chain Disruptions:

A surplus of inventory can disrupt the delicate balance of a well-managed supply chain. Manufacturers may face challenges in adjusting production schedules to align with actual demand, leading to inefficiencies that ripple through the entire supply chain. This can strain relationships with suppliers and result in increased lead times.

Customer Satisfaction Issues:

Unfulfilled customer orders due to inventory mismanagement can lead to dissatisfaction. When products are not readily available, customers may turn to competitors, damaging the business’s reputation. Consistently poor customer experiences can have long-lasting effects on brand loyalty and trust.

Increased Holding Costs:

Beyond the direct costs associated with warehousing, excess inventory may lead to increased holding costs. These costs include security measures, climate control, and additional labor to manage and maintain the surplus stock. Businesses must carefully assess these costs to understand the full impact on their bottom line.

Strategic Planning Challenges:

Effective strategic planning relies on accurate forecasting and demand management. Excess inventory disrupts this process by distorting demand signals. This, in turn, makes it difficult for businesses to make informed decisions regarding production, procurement, and market positioning.

The effects of excess inventory are multifaceted, impacting various aspects of a business’s operations and financial health. To mitigate these challenges, businesses must adopt proactive inventory management strategies, embrace technological solutions, and maintain a keen focus on market dynamics to ensure optimal stock levels that align with actual demand.

How To Manage Excess Inventory

Excess inventory can pose significant challenges for businesses, impacting their cash flow and overall operational efficiency. Effectively managing excess inventory is crucial to ensure that resources are utilized optimally. In this guide, we will delve into key strategies to help businesses navigate and address the issue of excess inventory.

Regular Inventory Audits:

Regularly conducting comprehensive inventory audits is a fundamental step in managing excess inventory. These audits provide insights into which products are overstocked, enabling businesses to make informed decisions on adjustments and prevent future overages.

Demand Forecasting:

Implementing robust demand forecasting processes helps businesses anticipate market trends and customer preferences. Accurate forecasting minimizes the risk of overstocking and ensures that inventory levels align with actual demand, preventing excess inventory issues.

Strategic Vendor Relationships:

Cultivating strong relationships with suppliers is essential for efficient inventory management. Open communication with vendors allows businesses to adjust order quantities based on real-time demand, preventing the accumulation of excess stock.

Discounts and Promotions:

Offering discounts and promotions on slow-moving or excess inventory can stimulate sales and help clear out surplus stock. Implementing targeted marketing strategies to highlight these promotions can attract customers and generate revenue.

Diversify Sales Channels:

Expanding sales channels, such as leveraging e-commerce platforms or exploring new markets, can help reach a broader customer base. Diversification reduces dependence on a single market and facilitates a more even distribution of inventory.

Implement Just-In-Time (JIT) Inventory Systems:

JIT inventory systems help minimize excess inventory by ensuring that products arrive just in time to meet customer demand. This approach reduces holding costs and mitigates the risk of overstocking.

Collaborate with Non-profit Organizations:

Consider partnering with non-profit organizations for donations or collaborations. This not only contributes to corporate social responsibility but also helps in reducing excess inventory through charitable initiatives.

Continuous Monitoring and Data Analysis:

Invest in advanced inventory management systems that allow for real-time monitoring and data analysis. These systems can provide actionable insights, enabling businesses to make timely adjustments to inventory levels and prevent excess stock.

Effectively managing excess inventory requires a multifaceted approach that encompasses regular audits, strategic forecasting, collaborative vendor relationships, and innovative marketing strategies. By implementing these strategies, businesses can not only reduce excess inventory but also enhance overall operational efficiency, ultimately contributing to sustained growth and profitability.

What Is Excess Inventory

Excess inventory refers to the surplus stock of goods that exceeds the demand in the market, posing challenges for businesses in managing their supply chain effectively. This article delves into the causes, impact, and potential solutions associated with excess inventory.

Causes of Excess Inventory:

a. Overforecasting: Overestimating demand can lead to excessive production and, subsequently, excess inventory.

b. Changes in Consumer Behavior: Rapid shifts in consumer preferences can catch businesses off guard, resulting in excess stock of outdated products.

c. Supplier Issues: Delays in the supply chain can lead to an accumulation of inventory as businesses wait for raw materials or finished goods.

Impact on Businesses:

a. Financial Strain: Excess inventory ties up capital and incurs storage costs, impacting a company’s financial health.

b. Obsolescence: Products can become obsolete, leading to write-offs and further financial losses.

c. Reduced Profit Margins: Clearance sales to move excess inventory often come with discounted prices, reducing overall profit margins.

Negative Consequences for Supply Chain:

a. Logistical Challenges: Managing and storing excess inventory can strain logistics, leading to increased warehouse costs.

b. Increased Lead Times: The presence of excess inventory can result in longer lead times, affecting responsiveness to market changes.

Strategies to Mitigate Excess Inventory:

a. Demand Forecasting Improvement: Adopt advanced forecasting techniques to better predict market demand.

b. Lean Inventory Management: Implement just-in-time inventory practices to minimize excess stock.

c. Collaborative Supply Chain: Foster strong relationships with suppliers to ensure a smooth and timely supply chain.

Technology Integration:

a. Inventory Management Systems: Implementing robust inventory management systems can enhance real-time tracking and reduce the likelihood of excess stock.

b. Data Analytics: Utilize data analytics to gain insights into consumer behavior, enabling more accurate demand forecasting.

Regular Inventory Audits:

a. Periodic Reviews: Conduct regular reviews of inventory levels to identify and address potential excess stock issues promptly.

b. Dynamic Pricing Strategies: Implement dynamic pricing strategies to adjust prices based on demand, reducing the need for clearance sales.

Excess inventory is a challenge that businesses must navigate strategically to maintain a healthy and efficient supply chain. By understanding the causes, recognizing the impact, and implementing proactive solutions, companies can minimize the risks associated with surplus stock, ensuring a more resilient and profitable operation.

How To Sell Excess Inventory

Managing excess inventory is a common challenge for businesses, and finding efficient ways to sell surplus stock is crucial for maintaining a healthy bottom line. In this guide, we will explore strategic steps on how to sell excess inventory effectively.

Implement a Dynamic Pricing Strategy:

One of the most effective ways to move excess inventory is by implementing a dynamic pricing strategy. Adjust prices based on demand, seasonality, and market trends. Offering discounts, bundling products, or introducing limited-time promotions can create a sense of urgency among potential buyers.

Leverage Online Marketplaces:

Take advantage of popular online marketplaces to reach a broader audience. Platforms like Amazon, eBay, and Etsy allow businesses to showcase their excess inventory to a global customer base. Optimize product listings with relevant keywords and high-quality images to attract potential buyers.

Explore B2B Liquidation Platforms:

Consider partnering with B2B liquidation platforms that specialize in handling surplus inventory. These platforms connect businesses with buyers looking for bulk purchases, providing a quick and efficient way to sell excess stock. Ensure that your products are accurately listed, and provide detailed information about their condition.

Engage in Targeted Marketing Campaigns:

Develop targeted marketing campaigns to reach specific customer segments interested in your excess inventory. Utilize email marketing, social media advertising, and content marketing to promote special deals and discounts. Highlight the value proposition of your products and emphasize the limited availability to create a sense of exclusivity.

Collaborate with Resellers and Distributors:

Build partnerships with resellers and distributors who specialize in your industry. They may have established networks and channels to move excess inventory quickly. Offer attractive incentives such as volume discounts or exclusive deals to encourage collaboration.

Optimize Your Website and E-commerce Store:

If you have an e-commerce platform, optimize it for search engines and user experience. Ensure that your excess inventory is prominently featured, and use relevant keywords to improve search engine visibility. Streamline the checkout process to encourage swift purchases.

Bundle Products Strategically:

Create product bundles or packages to incentivize customers to buy more. This not only helps in selling excess inventory faster but also increases the average transaction value. Clearly communicate the cost savings and benefits of purchasing bundled products on your marketing channels.

Monitor and Adjust Inventory Levels Regularly:

Implement a robust inventory management system to monitor stock levels continuously. By staying proactive, you can identify slow-moving items and take corrective actions promptly. Regularly assess market conditions and adjust your selling strategies accordingly to stay ahead of the competition.

Effectively selling excess inventory requires a strategic and proactive approach. By implementing dynamic pricing, leveraging online platforms, engaging in targeted marketing, and exploring collaborations, businesses can optimize their surplus stock management and maintain a healthy financial position. Regularly reassessing inventory levels and adjusting strategies will ensure a streamlined and efficient process for selling excess inventory.

Conclusion:

In conclusion, as businesses grapple with excess inventory challenges, embracing cutting-edge supply chain technologies becomes paramount. Qodenext emerges as a transformative force, offering advanced solutions to streamline processes, mitigate risks, and elevate supply chain efficiency. In the intricate dance of supply and demand, staying ahead with Qodenext ensures a resilient and profitable future for businesses.

FAQ: 8 Ways To Deal With Excess Inventory

1.What is excess inventory, and why is it a concern for businesses?

Excess inventory refers to surplus stock beyond demand, leading to increased holding costs and reduced profit margins. It’s a concern as it hampers supply chain efficiency and financial health.

2.How can businesses prevent excess inventory?

Employ proactive strategies such as demand forecasting, data analytics, and collaborative planning to align inventory levels with actual demand.

3.What are the effects of excess inventory on a company’s bottom line?

Excess inventory negatively impacts profitability by increasing holding costs, tying up capital, and leading to potential obsolescence.

4.How can excess inventory be efficiently managed?

Efficient management involves dynamic pricing, inventory optimization, and adopting agile supply chain practices to respond swiftly to market changes.

5.What innovative approaches exist for selling excess inventory?

Explore online marketplaces, strategic partnerships, and liquidation channels to turn excess inventory challenges into profitable opportunities.

6.How do technology trends contribute to managing excess inventory?

AI-driven demand forecasting, blockchain for transparency, and IoT-enabled inventory tracking are crucial in effectively managing excess inventory.

7.How does Qodenext revolutionize excess inventory solutions?

Qodenext employs advanced technologies to streamline supply chain processes, reduce excess inventory, and enhance overall efficiency for businesses.

8. How can data analytics help in reducing excess inventory?

Data analytics enables businesses to make data-driven decisions by identifying sales patterns, customer preferences, and demand fluctuations. By leveraging these insights, companies can forecast demand more accurately, optimise reorder points, and prevent stock accumulation that leads to excess inventory.

9. What role does supplier collaboration play in managing inventory levels?

Collaborating closely with suppliers allows businesses to align production schedules with real-time demand. Open communication ensures timely adjustments in order quantities, preventing overstocking and maintaining supply chain agility. This partnership-driven approach helps maintain optimal inventory levels and reduces waste.

10. How can businesses turn excess inventory into an opportunity?

Excess inventory can be strategically leveraged through creative sales campaigns, bundling offers, and collaborations with resellers or charitable organisations. These methods not only help recover tied-up capital but also enhance brand visibility, strengthen customer relationships, and promote corporate social responsibility.