Introduction

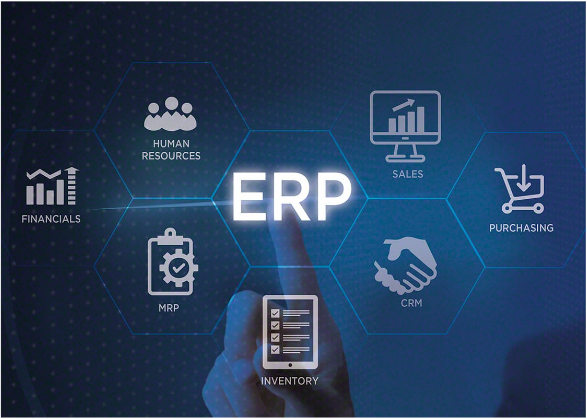

Ever found yourself amidst a labyrinth of acronyms while navigating the intricacies of business management? ERP and MRP—these seemingly perplexing terms may puzzle many. Fret not! In this guide, we’ll demystify the puzzle of ERP vs MRP, unveiling their meanings, discerning their roles, and discovering how each can be a steadfast ally on your journey to business triumph.

Decoding ERP and MRP: Beyond the Letters

ERP (Enterprise Resource Planning):

Conceptualize it as the system architect, meticulously coordinating a unified synergy across varied business processes, extending from financial management to human resources, all centralized within a nexus. It surpasses a mere tool, evolving into the esteemed ally and confidant of your business.

MRP (Material Requirements Planning):

Unveiling the specialized craftsman within the ERP lineage, MRP assumes the role of a precision engineer, entirely devoted to the complexities of manufacturing. With scrupulous attention, it ensures the precise alignment of materials in both spatial and temporal dimensions, proactively averting any potential disruptions in the production process.

Spot the Differences: ERP vs MRP

Optimizing Organizational Efficiency:

- ERP: A versatile giant addressing diverse organizational needs from boardrooms to production floors.

- MRP: A specialized expert in the nuances of manufacturing, ensuring a seamless production line.

Integration and Collaboration:

- ERP: Unifies departments, fostering collaboration across the organization.

- MRP: Orchestrates manufacturing operations, ensuring meticulous synchronization.

Customization and Scalability:

- ERP: A skilled tailor crafting bespoke solutions for your business, adapting and expanding with your enterprise.

- MRP: A fashion designer specifically for your production line, tailoring solutions to manufacturing intricacies.

Objectives of MRP

Goals of Material Requirements Planning, or MRP:

Optimal Inventory Management: Maintain timely raw material availability while strategically balancing inventory levels to minimize excess stock.

Precision in Production Schedules: Create production schedules that ensure a smooth, interruption-free manufacturing process.

Resource Optimization: Resource optimization is the process of matching labor and equipment to the needs of production in order to maximize operational effectiveness.

Cost-Effective Operations: To improve overall cost-effectiveness, use productive production and procurement procedures.

Improved Customer Service: Make sure resources are available on time, which will enable order fulfillment to happen quickly and lead to happier customers.

Cut Lead Times: Keep lead times to a minimum in order to quickly adjust to shifting requirements and market demands.

Data Precision: To ensure dependability in lead times and inventory levels, rely on precise data for efficient planning.

Waste Minimization: To reduce waste during production, use accurate material planning procedures.

Strategic Planning Support: Provide valuable insights into future material requirements, supporting well-informed decision-making in long-term planning.

Role of ERP in Supply Chain Management

Process Integration:

Manufacturing, inventory management, and procurement are all unified by ERP, which acts as the architect. Effective communication and cooperation across the supply chain are ensured by this seamless integration.

Real-time data insight:

ERP, which serves as the backbone of information, provides real-time visibility into crucial components such as production schedules, inventory levels, and order status. Stakeholders are empowered to make quick decisions with precise information thanks to this timely data.

Demand Analysis and Forecasting:

ERP foresees variations in demand, allowing for accurate forecasting, thanks to sophisticated data analytics. By helping to optimize inventory levels, this capacity guarantees a flexible and efficient supply chain.

Effective Order Management:

ERP makes the complete order life cycle—from placement to fulfillment—more efficient. Lead times are shortened as a consequence, increasing operational effectiveness and customer responsiveness.

Supplier Relationship Management (SRM):

ERP maintains contracts, keeps an eye on suppliers’ performance, and improves procurement procedures in a watchful manner. As a result, the supply chain is more responsive and dependable.

Inventory Level Optimization:

ERP is the defender of inventory levels, keeping a perfect balance to avoid both overstocking and stockouts. This is known as inventory level optimization. A robust and reasonably priced supply chain is a result of this careful management.

Benefits of ERP in Supply Chain Management

Improved Visibility: Real-time insights into the supply chain for better decision-making.

Enhanced Collaboration: Integration fosters collaboration across supply chain departments.

Optimized Inventory Management: Accurate insights prevent overstocking or stockouts, reducing holding costs.

Streamlined Procurement Processes: Automation leads to cost savings and improved efficiency.

Efficient Order Fulfillment: Automation results in shorter lead times and increased customer satisfaction.

Cost Savings: Overall cost savings through process optimization and resource utilization.

Demand Planning and Forecasting: Accurate forecasting minimizes the risk of excess inventory or stockouts.

Compliance Management: Ensures compliance with regulations and standards in the supply chain.

Enhanced Customer Service: Provides accurate and up-to-date information for improved customer service.

Data-Driven Decision-Making: Comprehensive reports and analytics empower data-driven decisions.

Benefits of Material Resource Planning

Inventory Optimization:

MRP helps to maintain ideal stock levels by making sure that there are enough resources on hand to fulfill demand for production. By minimizing surplus inventory, holding expenses are decreased.

Manufacturing Efficiency:

MRP helps to ensure a smooth and effective manufacturing process by identifying the materials required and when they should be delivered. This lowers idle time, prevents bottlenecks, and improves overall production efficiency.

Resource Utilization:

MRP maximizes the use of labor and equipment by matching production requirements with material availability. This reduces idle time for resources and improves overall operational effectiveness.

Cost Reduction:

By avoiding material overstocking and reducing production process interruptions, MRP helps cut costs. Lower holding costs, fewer urgent orders, and total cost savings result from this.

Lead Time Reduction:

By coordinating the manufacturing and procurement processes, MRP aims to reduce lead times in the supply chain. Faster reactions to shifting client needs and market demands are made possible by this reduction.

Better Order Fulfillment:

MRP helps to improve order fulfillment by guaranteeing the timely availability of materials. Ensuring client satisfaction through timely delivery and meeting requests is imperative.

Demand Planning and Forecasting:

Tools for demand planning and forecasting are frequently included in MRP systems. Organizations are able to forecast changes in demand and modify production schedules in response by examining historical data and market patterns.

Improved Communication:

MRP encourages improved coordination and communication between the various departments that are involved in the production process. This minimizes mistakes and enhances teamwork by guaranteeing that everyone is using the same data.

Waste Reduction:

MRP helps reduce waste in the production process by providing precise material planning and inventory control. This involves cutting back on extra materials that might eventually decay or become outdated.

Support for Long-Term Strategic Planning:

MRP offers insights into future material requirements based on predictions and production schedules, which helps with long-term strategic planning. This aids organizations in making well-informed choices on the distribution and allocation of resources.

FAQs

What is ERP?

ERP, or Enterprise resource planning, or ERP, is a complete software program that unifies and controls a range of internal business operations.

What distinguishes ERP from MRP?

Material Requirements Planning, or MRP, is a subset of ERP that focuses on managing materials for manufacturing, whereas ERP is a more comprehensive system that encompasses various activities.

What are the advantages of ERP for supply chain management?

ERP improves supply chain processes’ efficiency, visibility, and teamwork. It facilitates strategic decision-making, gives real-time data, and unifies several divisions.

Is ERP adaptable to particular business requirements?

Yes, ERP systems may frequently be tailored to meet the specific requirements of a company. They can be scaled up or down as the business expands to meet the needs of a particular industry.

What industries benefit most from implementing ERP and MRP systems?

ERP and MRP systems are versatile, benefiting industries like manufacturing, retail, healthcare, and logistics.

Can businesses integrate ERP and MRP solutions seamlessly?

Yes, many ERP systems include MRP modules, enabling seamless integration for comprehensive business management.

Conclusion

In conclusion, the dynamic synergy of ERP and MRP in supply chain management is a game-changer for companies seeking efficiency and strategic vision. With the powerful partnership of these tools, optimized by Qodenext, organizations can navigate industry changes with resilience, ensuring a synchronized flow of materials and streamlined operations.