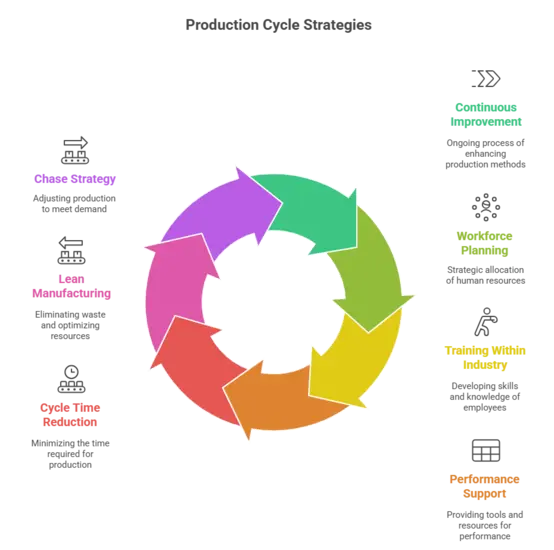

As a business owner, you must have struggled with delays, inefficiencies, and bottlenecks in your production cycle. In today’s fast-paced era, efficiency and speed win the game. It’s why implementing some key production cycle strategies to maximise your business’s efficiency and productivity is crucial.

Whether you’re a small business owner or a seasoned industry professional, understanding how to streamline your production cycle can be the game-changer you’ve been seeking. But what are these key production cycle strategies? Don’t worry! Let’s explore 7 such strategies together with QodeNEXT.

Effective Production Cycle Strategies you must know

1. Continuous Improvement in production cycle

Continuous improvement is a strategy that believes in the gradual and iterative improvement of productivity and other key business goals over time. Instead of focusing on a life-changing one-time transformation, this strategy is based on the gradual and continuous improvement achieved over time.

This never-ending process includes three key stages. The first stage deals with the identification of key areas and the scope of improvement. After identification, solution suggestions from various individuals and personnel are gathered. The second stage deals with the implementation of the best solutions.

The third stage deals with watching the solutions do their magic and focusing on what more can be done to maximise the improvements.

2. Workforce Planning in production cycle

Workforce planning (also known as labour planning) refers to the process of analysing and planning an organisation’s current and future workforce. From forecasting labour demand to identifying talent gaps, it encompasses all such aspects.

Workforce planning is essential as it helps you identify skill gaps, employee turnover, etc.

By aligning the workforce with production requirements, organisations can optimise efficiency, productivity, and cost-effectiveness.

With effective workforce planning, organisations can avoid labour shortages or excesses, minimise production bottlenecks, and maintain optimal staffing levels. This strategic approach helps streamline operations, improve resource allocation, and meet production targets.

Additionally, workforce planning enables organizations to respond to changing market demands, technological advancements, and other factors that impact production, ensuring a competitive advantage in the marketplace.

3. Training Within Industry

This strategy originated in the United States during World War II. During this time, there was a shortage of trained personnel in war fields and related industries.

The Training Within Industry (TWI) helped in solving this labour shortage using a fourfold model, which focused on job instruction, job methods, job relations, and program development. This strategy proves to be a structured approach to training, problem-solving, and employee engagement, resulting in a more streamlined and effective production cycle.

It helps in achieving maximum productivity from new employees within a constricted time frame. After its tremendous success in World War II, it has been used by organisations to optimise their production processes and drive long-term success.

4. Performance Support in production cycle

Performance support is a strategy that focuses on providing and involving the employees in practical learning moments designed according to the floor requirements. It focuses on practical learning, thus facilitating the recognition of the challenges that employees face in the field.

Besides focusing on practical aspects of already acquired skills, it also stresses developing and acquiring new skills or applying an already learned skill in a new way.

By integrating performance support into the production cycle, companies can promote continuous learning, enhance problem-solving capabilities, and foster a culture of self-improvement. This strategy not only helps individuals overcome obstacles but also contributes to overall productivity, efficiency, and quality within the company. It enables employees to perform their tasks with confidence and accuracy, leading to better outcomes and business success.

5. Cycle Time Reduction

As the name suggests, this strategy focuses on minimising or reducing the time taken to complete a production cycle. It focuses on identifying and eliminating non-value-added activities, bottlenecks, and inefficiencies to achieve shorter cycle times.

Shorter cycle times allow faster delivery which results in improved customer satisfaction.

Besides faster delivery, it also streamlines the operational processes, thus reducing resource usage, operational costs, and wastage. To achieve cycle time reduction, companies employ various strategies such as process optimization, automation, standardisation, and continuous improvement initiatives like Lean or Six Sigma.

6. Lean Manufacturing

Originating from the Toyota Production System (TPS), this production cycle strategy is a systematic approach that stresses optimising the materials and information flow within the production cycle. This way, it aims to eliminate waste, maximise efficiency and optimise resources within the production cycle.

At its core, lean manufacturing focuses on the identification and elimination of non-value-added activities, commonly referred to as waste, which includes overproduction, excess inventory, defects, waiting time, unnecessary transportation, overprocessing, and underutilised talent. By reducing or eliminating these wastes, lean manufacturing aims to create a streamlined production flow that delivers high-quality products or services with minimal resources and lead time.

7. Chase Strategy

The Chase strategy is a simple strategy that focuses on ensuring that the production matches the demand requirements. It’s based on the principle of producing exactly what is needed when it is needed and in the quantities required. This strategy aims to match the production rate with the actual customer demand.

By synchronising production with demand, the company can optimise its resources and achieve greater efficiency in its operations. This strategy is particularly suitable for industries with short product life cycles, perishable goods, or industries where demand is highly unpredictable.

Do you want to revolutionise your production cycle efficiency and productivity? We bring you QodeNEXT and its unique solutions, which are tailored to meet your unique needs, thus taking your business’s productivity and efficiency to the next level. Unlock the full potential of your business with QodeNEXT’s comprehensive suite of hardware and software solutions. Go check out QodeNEXT’s services now!

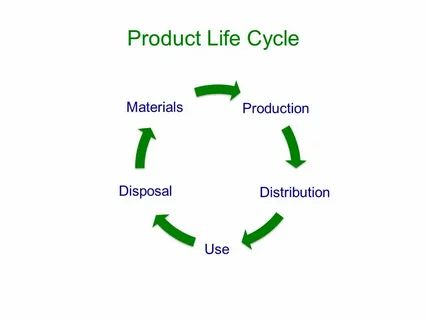

Benefits of Product Life Cycle Analysis:

The advantages of product life cycle tracking are:

What advantages are you getting from product life cycle tracking?

1.Accurately predicting market trends

2. Buying your investments at the right time

3. Planning product refreshes strategically .

Important benefits of product life cycle management are kept profitability and competitive ability.

Product Life cycle Marketing Strategies

Effective product life cycle marketing strategies differ according to life cycle stage. In the introduction stage, become known. In the maturity stage, “product life cycle marketing strategies” focus on differentiation and loyalty.

Time-line activities for:

Launch: Brand building campaigns

Growth: Market growth strategies

Maturity: Increase customer retention

Decline: Harvest, or previously standard harvest mode now discontinued. Mastering these concepts drives business success.

Wrapping Up

We’ve explored some key production cycle strategies by which you can optimise every step of your production process. In today’s dynamic business world filled with cutthroat competition, these strategies are your powers to streamline your business operations, reduce costs and enhance overall productivity.

By adopting these strategies and continually refining production processes, businesses can stay ahead of the competition, adapt to changing market demands, and deliver high-quality products efficiently.

Stay ahead of the competition, maximise efficiency, and ensure customer satisfaction with our indispensable solutions at your disposal. Don’t forget to check out QodeNEXT. Get in touch with us now to help you make the best choice to manage your fleet and optimise your process!

FAQ: Production Cycle

1. What is workforce planning in production cycle?

Workforce planning (also known as labour planning) refers to the process of analysing and planning an organisation’s current and future workforce.

2. What is the continuous improvement strategy?

Continuous improvement is a strategy that believes in the gradual and iterative improvement of productivity and other key business goals over time.

3. What is the performance support strategy?

Performance support is a strategy that focuses on providing and involving the employees in practical learning moments designed according to the floor requirements.

4. What is the cycle time reduction strategy?

As the name suggests, this strategy focuses on minimising or reducing the time taken to complete a production cycle.

5. What is lean manufacturing?

Lean Manufacturing is a systematic approach that stresses optimising the materials and information flow within the production cycle.