The demand-supply cycle is a constant battle for inventory managers. They spend many sleepless nights to match customer demand while keeping inventory costs under control.

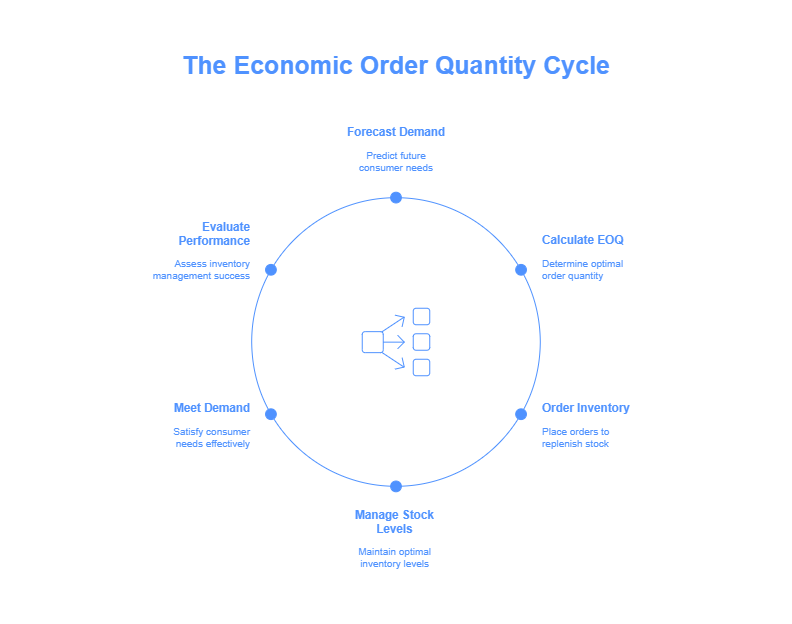

Managers have to juggle inventory management without the risk of stockouts and figure out ways to calculate the ideal order size. In this blog, we’ll understand the working principle of economic order quantity and how they are a valuable method to maintain optimum inventory control.

Economic Order Quantity: The Basics of Inventory

The best product-scheduling technique, economic order quantity is the ideal order size a company buys to match demand while minimizing inventory costs like shortage of materials, storage and holding. Ford. W Harris, the OG production engineer developed this inventory formula to reduce demand, supply, and cost escalations in supply chain management.

The EOQ inventory model indicates the optimum delivery of units to decrease the cost related to the purchase, sales, and product storage.

The method assumes that demand is constant in a fixed period and the purchase is done entirely when the stock reaches zero.

Enough theoretical talk! Let’s dissect the formula of economic order quantity.

EOQ Formula: In-Depth Guide

The formula for the EOQ inventory model is:

Q = √2 DS/H

- D = Total No. of Units purchased per year

- S = Order cost per purchase

- H = Holding cost per unit annually

What is Economic Order Quantity Telling You?

The aforementioned formula identifies the optimal product units to order. It can be modified for different production levels and order requirements. The main goal of the formula is maintaining a proper cycle between supply, demand, and storage of goods. By calculating the product units, your company can control the amount of cash tied up in the inventory balance.

When the inventory falls under a specific limit, the company can calculate the exact units to purchase for the next order cycle. By specifying a trigger point at the start, the company avoids running out of inventory to fulfil customer orders. This enhances customer satisfaction and reduces revenue loss.

Let’s check how economic order quantity is used in a real-life scenario.

EOQ in Inventory Management: Real Practice

Rahul owns a small bakery in a nearby locality. He relies heavily on flour to bake cookies, cakes, pastries, and other baked items. Flour is a key ingredient to ensure regular customer demand at his shop.

To optimise the flour inventory, Rahul uses the economic order quantity formula to estimate sales and production needs. Here’s a glimpse:

- He utilises 500 kilograms of flour every month based on historical data. D = 500.

- The ordering cost for flour is fixed at INR 50 including transportation, administrative, labour, and other charges. S = 50.

- The holding cost is 0.10 per kilogram including storage, holding, and capital cost of inventory. H = 0.10.

Applying the economic order quantity formula for Rahul’s bakery.

EOQ = √2*500*50/0.10

EOQ = 707 kilograms

The optimal order quantity for Rahul is 707 kilograms assuming the demand is constant throughout the year. By ordering 707 kilograms per order, he can minimise inventory costs, fulfil customer orders, and streamline his shop’s daily operations.

Let’s take the discussion ahead with the importance of EOQ in supply chain management.

The Importance of Economic Order Quantity

To manage fluctuations in consumer demand, professionals around the world utilise this formula to create a robust supply chain model. Inventory techniques like the EOQ help you understand the sweet spot between buying products to meet demand and maintaining an extra buffer to mitigate emergencies.

The end goal is to avoid low stockouts during peak demand – leading to disappointed customers. Similarly, you have to avoid the opposite situation where you overstock during low demand, leading to spoilage and high storage costs.

The Advantages of Economic Order Quantity

One of the best inventory techniques, economic order quantity is the best inventory management tool used by millions of warehousing staff worldwide. Here is a list of its benefits.

1. Cost Efficiency –

Ensures the balance of optimal product quantity by matching ordering costs(setup, handling, transportation) with holding costs like storage, material storage, and spoilage.

2. Enhanced Cash Flow –

You decide the right quantity at the right time, freeing up capital tied in inventory and allocating resources to other investments and operational needs, thus, increasing the company’s cash flow.

3. Simple Supply Chain Visibility

– The EOQ formula is pretty simple and easy to implement, meaning there are fewer disruptions in the supply chain process. Controlling inventory becomes efficient and less prone to errors.

4. Better Decision Making –

Inventory decisions shouldn’t be based on guess and pick alone. Economic order quantity provides a quantitative basis by marking the trade-offs between order and holding costs. Managers can minimize costs, save resources and prevent spoilage of goods.

5. Order Fulfilment –

Optimal EOQ maintains the availability of items for specific customer orders. This leads to greater customer satisfaction, brand loyalty, and a boost in sales.

However, despite the positive effects, the economic order quantity has some pitfalls.

Limitations of Economic Order Quantity (EOQ)

Lean supply chain systems present many challenges. Here are a few mentioned below.

The Economic Order Quantity (EOQ) model has long served as a foundational tool in inventory management, helping organizations minimize the total cost of ordering and holding inventory. However, in today’s rapidly evolving supply chain environment, especially within lean and multi-channel systems, EOQ presents several limitations. Below are the key challenges associated with using the EOQ model in modern supply chain practices.

1. Assumption of Constant Demand

EOQ assumes a steady and predictable demand throughout the year.

- Reality Check: In today’s markets, demand is anything but constant. Seasonal shifts, promotions, changing customer preferences, and external disruptions can lead to erratic demand patterns.

- Impact: Using EOQ in such a setting often leads to overstocking or stockouts, both of which are costly.

2. Batch Ordering and Zero Real-Time Adjustments

The EOQ model is based on bulk ordering—items are replenished in fixed quantities at regular intervals.

- Limitation: It does not accommodate real-time inventory visibility or dynamic restocking based on current sales or usage data.

- Modern Need: With the rise of IoT and real-time inventory systems, businesses now require adaptive replenishment strategies.

3. No Consideration for Lead Time Variability

EOQ assumes that lead times are consistent and predictable.

- Challenge: In lean supply chains or global sourcing models, lead times often vary due to shipping delays, customs clearance, or supplier inconsistencies.

- Risk: This assumption can lead to mismatched stock levels and poor service levels.

4. Inflexible to Multi-Channel Fulfillment

Modern supply chains are often multi-channel, involving e-commerce, physical retail, third-party logistics providers, and more.

- EOQ Limitation: The model doesn’t account for channel-specific demand fluctuations, fulfillment strategies, or varying service level agreements (SLAs).

- Result: Rigid ordering practices that may not align with actual operational needs.

5. Ignores Volume Discounts and Pricing Dynamics

The EOQ formula traditionally excludes price breaks or volume discounts offered by suppliers.

- Missed Opportunity: Businesses might miss out on cost-saving opportunities if they rigidly stick to EOQ rather than negotiating for bulk pricing or leveraging supplier offers.

6. Not Suited for Perishable or Obsolescent Goods

EOQ assumes indefinite product usability and doesn’t factor in shelf life or technological obsolescence.

- Implication: This is especially problematic for industries dealing with perishables, fashion, or electronics, where goods may lose value quickly.

7. Lack of Integration with Modern Inventory Systems

EOQ is a static formula, whereas modern systems use AI, machine learning, and predictive analytics for dynamic inventory control.

- Gap: Relying solely on EOQ prevents companies from taking advantage of integrated, data-driven systems that adapt to real-time changes.

8. Environmental and Sustainability Concerns

By encouraging large batch ordering, EOQ may inadvertently lead to increased carbon emissions due to warehousing, packaging, and transport inefficiencies.

- Modern Priority: Sustainable supply chain practices often prioritize smaller, more frequent shipments from local or regional suppliers.

Conclusion

Irrespective of the situation, economic order quantity remains the ideal solution for businesses to match order frequency and maximise profits. To assess the formula’s probability, do an internal analysis and ensure your demand, supply, and ordering points are the same. For further inventory control management and supply chain visibility, trust Qodenext to be your next-door ally in logistics solutions.

FAQs: Economic Order Quantity: Definition, Formula and Everything You Need to Know

1. What is EOQ and its assumptions?

To match the rising demand of customers, managers rely on the EOQ formula. However, there are basic assumptions governing the inventory calculating technique.

The ordering cost is fixed, and the demand is constant throughout the year.

2. Why is EOQ important?

Economic order quantity is a boon for companies looking to reduce inventory expenses and increase revenue. Maintaining a fine balance between the dynamic changes in the supply chain is hard and EOQ simplifies the process by creating a buffer zone between supply and demand.

3. What is EOQ and economic lot size?

EOQ relies on ordering batch items while economic lot size offers continuous delivery of products throughout the year. Both are different inventory tools used by companies to streamline their daily operations.

4. What is the EOQ tool for controlling?

The formula controls total annual cost, ordering, holding, and carrying costs. It manages the number of orders, quantity, and total reorder points.

5. How often should EOQ be calculated for a business?

EOQ should be recalculated regularly—quarterly or bi-annually—to reflect changes in demand, cost, or inventory conditions.

6. Can EOQ be used for perishable goods?

EOQ can be adapted for perishables, but it must factor in shelf life, spoilage risk, and more frequent ordering cycles.

7. What tools can automate EOQ calculations?

Inventory management software like SAP, Oracle NetSuite, or Zoho Inventory can automate EOQ based on live inventory data.

8. Is EOQ suitable for seasonal businesses?

Traditional EOQ assumes constant demand, so seasonal businesses need a modified EOQ model that includes demand variability.