In any business that sells products, whether they are tangible or intangible, it is the balancing act that determines success. What makes up the crux of this equilibrium is the distinction between demand planning vs supply planning. Nail it, and your profits increase; mess it up, and you wind up with either empty shelves or a mountain of stock you can’t sell. These two processes are the vital twin flues of contemporary supply chain management.

Round 1: Demand Planning – Figuring Out What People Want

In order to appreciate the distinction between demand planning vs supply planning, you need to start with the customer.

Demand planning is the critical activity to accurately anticipate what customers are going to buy, where they are going to buy it, and when they are going to buy it. In simple terms, what is demand planning? It’s the art and science of predicting customer demand with accuracy so the business can prepare its resources accordingly.

You can consider the demand planning team as the company’s internal market research arm looking into the future. The answer to what demand planning is is a mixture of science and human perceptiveness that predicts future requirements. Patrick Does This Forecast Goes With That Number? This forecast turns into the biggest number in the business, since every other determination emanates from this one.

Responsibilities of a Demand Supply Planner (Demand Side)

The demand-side planner relies on multiple sources of information to produce a sound prediction. They are not basing their analyses solely on historic sales; rather, they’re incorporating anything that could impact future sales:

1. Past purchasing history:

Examining historical shopping habits, seasonal peaks, and year-on-year rises.

2. Market Intelligence:

Collecting a cloud of information about what competitors are doing, economic patterns, and significant industry changes.

3. Promotional Plans:

Accounting for the anticipated sales gain of marketing campaigns, discounts, and promotional activities. (Find out how intelligent systems distill sales data in our report on Supply Chain Management).

The end product of this process is a well-defined, consensus-based sales forecast, the instruction sheet that is handed to the following group.

Round 2: Supply Planning, Building How to Build It

Supply planning decides the how and where if demand planning is the what and when.

With a buyer’s expectation defined (demand planning), supply planning is the crazed act of lining up all required raw materials, production capacity, and logistics to fulfill that number, no matter how much or how little it is.

Think of the supply planner as the operations professional. They use the sales forecast (the blueprint) to develop the MPS (the construction plan).

Demand Supply Planner (Supply Side) Role

The Supply-side Planning is a planner who budget the Furious. It focuses on the physical day-to-day reality of the activities of the company. Managing flowers, critical constraints that cost time and money, is while they handle pivotal constraints that consume both time and cash:

1. Material Sourcing and Procurement:

Ordering and receiving the correct amount of raw material. They honor the tight lead times suppliers dictate.

2. Plant Capacity Planning:

Check the plant has sufficient machine and labor capacity to meet the amount without costly overtime or bottlenecks.

3. Inventory Management:

Deciding where to store finished goods and how much safety stock to keep to handle unexpected surges.

The difficulty of managing both demand planning vs supply planning, in which demand is flexible (it can change tomorrow) and supply is rigid (it takes weeks to produce a product). In many organizations, the demand supply planner bridges both sides, ensuring forecasts and resources align seamlessly.

The Core Relationship: Demand Planning and Supply Planning

The best companies realize that demand planning vs supply planning isn’t a battle; it needs to be almost symbiotic. That’s why demand planning and supply planning must work together like two halves of the same system, constantly adjusting to market changes and operational constraints. Both constantly have to be in sync:

- Demand planning gives the need.

- Supply planning gives the need to supply the need.

That communication handful at which this coordination takes place in a couple of weeks’ iterations is S&OP, or Integrated Business Planning (IBP). Where the demand team says, “We can sell 150 000 units,” and the supply team says, “Given the materials, we can make only 130 000 units.”They then collaborate to close the 20,000 hole, either by lowering the demand target or by increasing supply.

The goal is to create a single, unified plan that everyone in the company, from sales to production, can follow. This balance of demand planning and supply planning prevents costly mistakes like overstocking or stockouts.

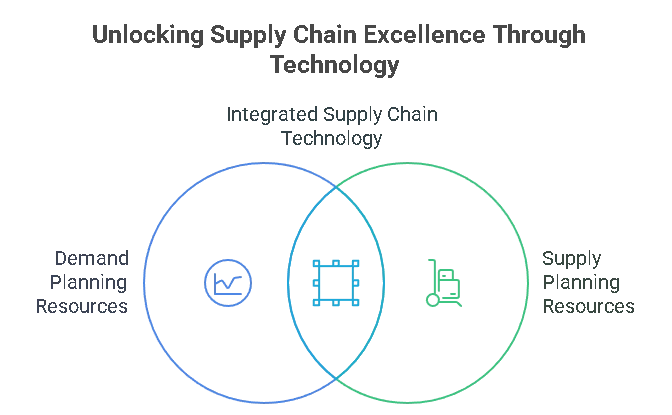

Demand Planning vs Supply Planning: Finding the Best Resources for Supply Chain Planning

To be good at both demand vs supply planning, companies need “best of breed” technology and trustworthy data. It’s not the work of isolated spreadsheets anymore.

Demand Planning vs Supply Planning: Best Tools for Supply Chain Planning output= To all planners and managers that want better resources for supply chain planning, this is where your focus should be. Some of the most valuable resources for supply chain planning are advanced forecasting software, AI-driven analytics, and real-time inventory visibility tools.

1. Real-Time Data Visibility:

Planners need to know exactly how much inventory is on hand, in transit, and sitting at the supplier location. These results provide exactly the level of visibility we aim to provide in our industry-focused supply chain management offerings at Qodenext; the supply planner will always be able to work with the right numbers.

2. Accuracy of Forecast:

The tools should be able to perform sophisticated statistics and even run on AI/machine learning to analyze the data and come up with accurate predictions, rather than just relying on historical averages.

3. Cross-Functional Platform:

The most critical resource for supply chain planning is a common platform where demand and supply planners have access to the same data and can view each other’s updates and work together in real-time to solve problems. This shared virtual space removes the back-and-forth slow emails and contradictory reports.

What separates demand planning vs supply planning? Having the right technology in place turns the demand-supply planner from a reactive role to a proactive, strategic one.

Conclusion: Striking the Right Balance

Balancing demand planning and supply planning isn’t about choosing one over the other—it’s about making them work hand in hand. Demand planning helps you understand what customers want, while supply planning ensures you have the resources ready to deliver on that promise. When both sides are aligned, businesses avoid the frustration of stockouts, reduce waste, and keep customers happy.

In today’s fast-moving world, the companies that thrive are the ones that use reliable data, smart tools, and strong collaboration to bring these two processes together. At Qodenext, we believe that mastering this balance is the key to building resilient, future-ready supply chains.

FAQs: Demand Planning vs Supply Planning

1. What is the difference between production planning and demand planning?

Demand planning is the sales volume prediction (intention of the customer to buy). Production planning is a part of supply planning that determines the supplier schedule (how many units to build/day/week) based on this predicted sales volume. Demand informs production execution.

2. Supply Planning vs Production Planning: What is the difference?

Supply planning is the overarching strategic role that deals with all resources (materials, inventory, logistics, and production). Production planning is the real-time scheduling based on how much you will be producing and how many operators are working on that shift. Production planning is just a part of the larger supply planning equation.

3. What is a practical example of demand planning?

One obvious example is a large electronics firm forecasting demand for a new tablet. The demand planner takes into account sales of the old model, a competitor’s product release date, and the size of the advertising budget. They project, “We will sell 300,000 tablets in North America for the month.” That figure is followed for all other supply planning activities.

4. What is a key step in the demand and supply planning process?

Consensus Forecasting is a key activity in the process. A critical step is consensus forecasting. This is where Sales, Marketing, and Finance’s pre-shipping statistical demand forecast is reviewed and agreed upon before going to the supply side. This is to ensure that everyone in the organization is focusing on the same goal.

5. What are the main duties in a Demand and Supply Planner description of work?

The job has two aspects: Forecasting Accuracy (working with sales data, and market trends) and Inventory Optimization (converting the forecast into production orders, running safety stock, and purchasing co-ordinating with procurement).

6. What are the major differences between demand and supply?

Demand forecasting is the activity (act of mathematically calculating for the next n days/months/years of business sales). The supply is the tangible facility (the real raw materials, factory hours, and logistics) to fulfill that expectation. It’s the number that forecasting gives; it’s the resources that supply gives.

7. What does “unconstrained demand” mean in demand planning?

Unconstrained demand is a sales forecast as if you had infinite factory capacity and materials. It reveals the real potential with the customer for that product. The supply planner then can take that number and try to get as close to that number with their own resource constraints.

8. Why do accurate supply chain planning resources matter so much?

Accurate supply chain planning resources (such as up-to-date software and quality end-to-end data capture tools) can prevent the astronomical costs of guessing. Improved planning decreases inventory holding costs, reduces the obsolescence of products, and prevents sales from going out of stock, which has a direct positive effect on the margin of profits.