In today’s highly competitive business landscape, efficient inventory management is vital to the success of any company. Among the various inventory management models, consignment inventory management has emerged as a popular and effective approach to optimize inventory control while minimizing costs. This model involves storing inventory at a customer’s location until the product is sold, at which point the customer pays for the inventory.

While the consignment inventory management model can offer significant benefits, it also poses some unique challenges. In this blog post, we will explore the consignment inventory management model, its advantages and disadvantages, and the best practices for implementing this inventory management strategy effectively.

What Is the Meaning of Consignment in the Context of Inventory Management?

Consignment in inventory management system refers to an arrangement between a supplier and a customer where the supplier places goods at the customer’s location, and the customer pays for the goods only after they sell them to the end consumer. This method allows suppliers to reduce the risk of holding excess inventory, while customers benefit by avoiding the need to purchase stock upfront.

In a consignment inventory management model, the supplier remains the owner of the inventory until the goods are sold. This means that the supplier retains the right to remove the inventory from the customer’s location or replace it with new items if they are not selling. The customer, on the other hand, is responsible for ensuring the security and proper storage of the consigned inventory.

Some key points to remember about consignment inventory management include:

- The supplier retains ownership of the inventory until it is sold to an end consumer.

- The customer is responsible for storing and protecting the inventory while it is in their possession.

- The customer pays for the inventory only after they sell it to the end consumer.

- The supplier may choose to remove or replace the inventory if it is not selling well.

- Consignment inventory management can help suppliers minimize the risk of holding excess inventory, while customers can benefit from lower upfront costs.

How Does Consignment Inventory Management Work?

Consignment inventory management is a business model where a supplier (consignor) retains ownership of the inventory until it is sold by the retailer (consignee). This means that the supplier retains the financial risk of the inventory until it is sold, and the retailer only pays for what they sell.

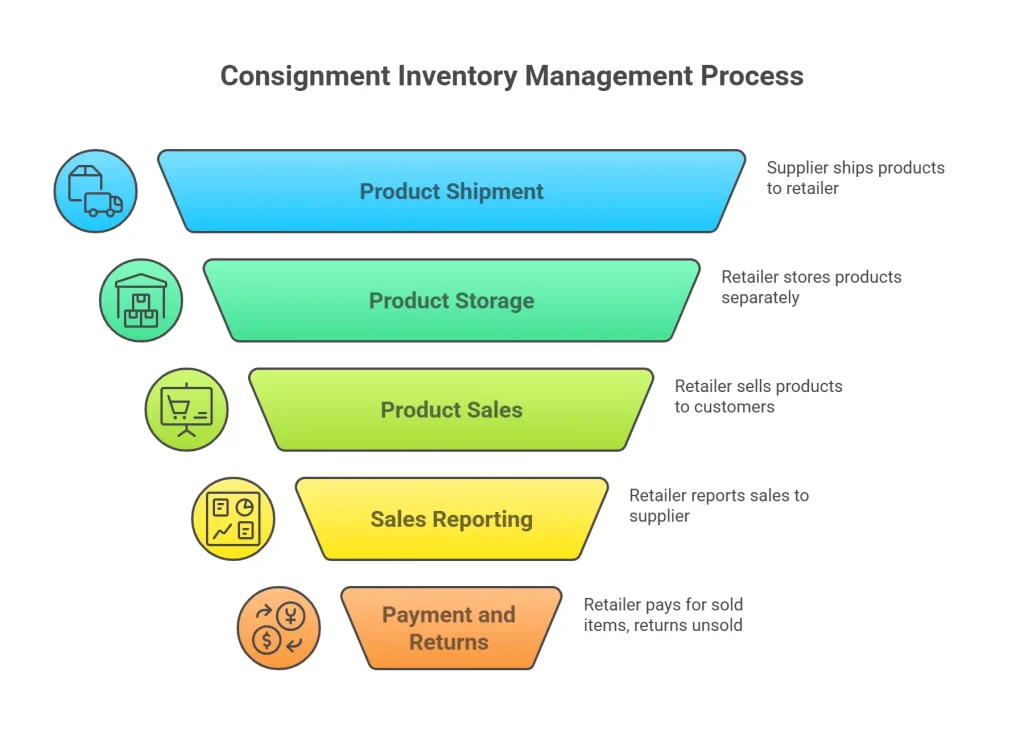

The steps involved in consignment inventory management:

Consignment inventory is a win-win setup where suppliers place their products at a retailer’s store, and the retailer pays only when the items are sold. Here’s how it works step-by-step:

STEP 1. Set the Ground Rules

The supplier and retailer agree on terms—like how long the products will stay, how much commission the retailer gets, and how payments will work.

STEP 2. Ship and Store

The supplier sends the products to the retailer, who stores them separately from their own stock to avoid mix-ups.

STEP 3. Sell to Customers

The retailer displays and sells the products, usually at a markup. The supplier still owns the items until they’re sold.

STEP 4. Share Reports and Pay Up

The retailer regularly updates the supplier about sales and remaining stock, then pays only for what’s been sold.

STEP 5. Return or Replace Unsold Stock

If something doesn’t sell, the supplier can take it back or switch it out for new items.

Consignment inventory management allows consignees to offer a wider range of products without incurring the financial risk of purchasing and owning inventory outright, while consignors can expand their reach to new markets without the upfront costs of creating their own retail channels ,This model helps retailers reduce risk and investment, while suppliers get more visibility for their products—without needing their own store.

Best Practices for Consignment Inventory Management

Consignment inventory management is the process of managing inventory that is owned by a supplier but is being stored and sold by a retailer. This type of arrangement can be beneficial for both parties, as it allows the supplier to maintain control over their inventory while also giving the retailer the ability to sell the products without having to make an upfront investment. To ensure successful consignment inventory management, several best practices should be followed.

1. Establish Clear Communication

Establishing clear communication between the supplier and the retailer is critical to the success of the consignment arrangement. This means that both parties should have a clear understanding of the terms of the agreement, including the payment terms, the consignment period, and any other relevant details. Additionally, regular communication should be maintained throughout the consignment period to ensure that both parties are aware of any issues or changes that may arise.

2. Implement a Robust Inventory Tracking System

A robust inventory tracking system is essential for effective consignment inventory management. This system should allow both the supplier and the retailer to monitor the inventory levels and sales data in real-time. It should be able to generate reports that provide insight into inventory turnover, sales velocity, and other key metrics. This data can help both parties to identify any issues or trends that may impact the success of the consignment arrangement.

3. Establish Clear Policies and Procedures

Establishing clear policies and procedures for handling damaged or unsold inventory is important to ensure that any issues are addressed in a timely and effective manner. This can help to minimize the impact on both parties. For example, the policy may include provisions for returning unsold inventory to the supplier, or for disposing of damaged inventory in a responsible manner.

4. Accurate Record-Keeping

Accurate record-keeping is essential for effective consignment inventory management. This includes keeping detailed records of all transactions, including inventory transfers, sales, and payments. Accurate record-keeping can help to prevent disputes and ensure that both parties have a clear understanding of the status of the consignment arrangement at all times.

5. Consignment Agreement

Having a consignment agreement is important to ensure that both parties are clear on the terms and conditions of the arrangement. The agreement should include details such as the consignment period, payment terms, and provisions for handling damaged or unsold inventory. It should also clearly outline the responsibilities of each party.

6. Consignment Inventory Audit

Conducting a consignment inventory audit on a regular basis is important to ensure that the inventory levels and sales data are accurate. This can help to identify any discrepancies or issues that may need to be addressed. The audit should be conducted by an independent third party to ensure that it is unbiased and impartial. By following these six best practices for consignment inventory management, both the supplier and the retailer can ensure that the arrangement is successful and mutually beneficial.

7. Set Realistic Expectations

It is important to set realistic expectations for the consignment arrangement. Both parties should have a clear understanding of the expected sales volume, the consignment period, and the payment terms. This can help to prevent misunderstandings or disputes down the line.

8. Optimize Inventory Levels

Optimizing inventory levels is key to ensuring that the consignment arrangement is successful. This means maintaining an appropriate level of inventory based on sales volume and trends. Overstocking can lead to excess inventory that may not sell, while understocking can lead to missed sales opportunities.

9. Regularly Evaluate Performance

Regularly evaluating the performance of the consignment arrangement is important to identify any issues or areas for improvement. Both parties should review the sales data and other relevant metrics regularly to ensure that the arrangement is meeting expectations.

10. Ensure Quality Control

Ensuring quality control is important to maintain the integrity of the products being sold. The retailer should have a process in place to inspect and verify the quality of the inventory before it is put on display or sold. This can help to prevent any issues with damaged or defective products.

11. Maintain Clear Channels of Communication

Maintaining clear channels of communication between the supplier and the retailer is essential to the success of the consignment arrangement. Both parties should have a designated point of contact who is responsible for maintaining regular communication and addressing any issues that may arise.

12. Consider Market Trends

Finally, it is important to consider market trends when managing consignment inventory. This includes keeping up-to-date on industry trends, changes in consumer preferences, and other relevant factors that may impact sales. By staying informed, both parties can make informed decisions about inventory levels, pricing, and other important factors.

Conclusion

In conclusion, we can say that managing consignment inventory can be a challenging task for businesses, but with the right model and best practices in place, it can be a profitable and efficient way to do business. Companies that implement a consignment inventory model can benefit from reduced inventory carrying costs, increased product visibility, and better control over stock levels.

It’s important to work with a trusted partner like Qodenext to ensure that consignment inventory is stored and managed properly. Qodenext offers state-of-the-art inventory management solutions that can help businesses optimize their supply chain and minimize inventory waste. With their expertise and experience, businesses can streamline their consignment inventory processes and focus on their core operations.

If you are looking for a reliable and efficient consignment inventory management solution, then Qodenext is the perfect partner for you. Get in touch to learn more about the services and how it can help your business succeed.

FAQs on Consignment Inventory Management

1. What is consignment inventory management?

It’s a model where the supplier places inventory at the retailer’s location, and the retailer pays only after the product is sold.

2. Who owns the inventory in a consignment arrangement?

The supplier retains ownership until the goods are sold to the final customer.

3. What are the key benefits of consignment inventory?

Lower upfront costs for retailers, better product visibility, and reduced holding risks for suppliers.

4. What are the risks associated with consignment inventory?

Inventory damage, poor sales performance, and disagreements on unsold stock responsibilities.

5. How is consignment inventory tracked?

Using inventory management software that monitors real-time stock levels, movement, and sales.

6. What should be included in a consignment agreement?

Payment terms, consignment period, inventory return policies, and responsibilities of both parties.

7. How often should inventory audits be conducted?

Regularly—monthly or quarterly—to ensure stock accuracy and resolve discrepancies.

8. Can unsold inventory be returned to the supplier?

Yes, based on terms defined in the consignment agreement.

9. Is consignment inventory suitable for all businesses?

It works best in industries with stable relationships and predictable demand, such as retail, pharma, and electronics.

10. How can Qodenext help with consignment inventory?

Qodenext offers automated inventory tracking, real-time insights, and streamlined reporting for efficient consignment operations.