Change is bound to happen, and so is the expansion of global trade.

Trade methods have developed in tandem with the newest technological breakthroughs in the last few decades. These advancements have automated numerous processes, including the equipment and structures we utilize for storing and moving goods.

A prime illustration of this is seen in cold chain logistics.

Temperature-sensitive items are moved through a cold chain system. Like other products, it requires a lot of science and technology to maintain its cold temperature during transport.

This blog encompasses everything that you need to know about cold chain management including the technology that goes behind it, the requirements, and the obstacles that hinder the complex process.

So, let’s get started!

What Is Cold Chain Logistics?

The cold chain, as its name implies, is a method of managing logistics for items that need to be kept cold. This involves tasks like getting things ready, storing them properly, and transporting them along the chilled supply chain.

Lots of products, especially important ones, need to be stored at specific temperatures. If they aren’t, they can spoil and go to waste. When this happens, both the person transporting the goods and the person receiving them lose money.

Have you ever wondered how big companies like Nestle and Johnson & Johnson maintain their quality during shipment?

For food and pharmaceutical manufacturers, the cold chain is essential as it prevents product contamination during shipping and storage, ensuring their quality until they’re sold. These companies are always working on enhancing their cold chain management, even though it’s not their main area of expertise.

Different products have varying cold chain temperature requirements. However, here are the typical temperature requirements for different goods:

- Ambient fresh produce: kept between 57°F and 75°F

- Chilled fruits, vegetables, and dairy products: maintained between 45°F and 57°F

- Pharmaceutical drugs: stored between 36°F and 46°F

- Frozen meat and seafood: preserved between -0.5°F and 32°F

- Deep-frozen meat and seafood: frozen between -22°F and -0.5°F

Read further to know more about cold chain logistics.

The Components of Cold Chain Management

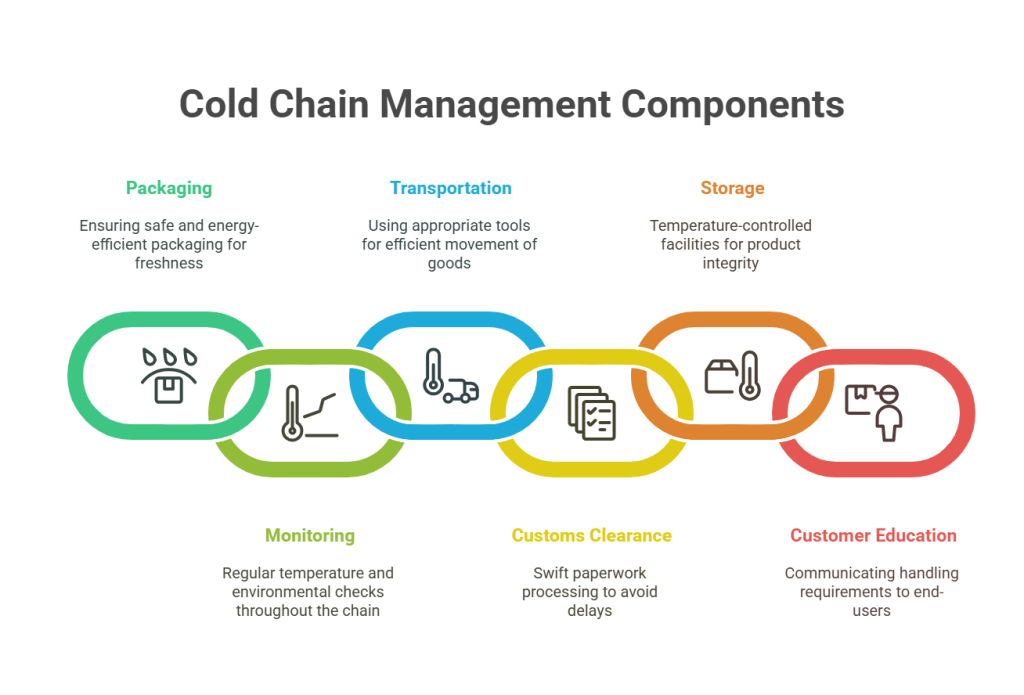

Now that we have a clear understanding of the cold chain definition, let’s explore its specific components.

There are six main parts to the cold chain process, and your company must implement each of them to ensure the safe transit and storage of your products.

1. Packaging

Making sure that your goods are packed safely and in energy-efficient materials is important. This helps maintain freshness even when there are short-term fluctuations in temperature.

2. Monitoring

Regularly checking temperature changes and environmental conditions throughout the supply chain is vital. Utilizing appropriate tools and equipment for this greatly benefits your operations.

3. Transportation

When you use the right tools and equipment for moving goods, it makes the task a whole lot easier. These tools include refrigerated vehicles, thermal blankets and bags, and insulated vacuum panels.

4. Customs Clearance

Ensuring all paperwork is cleared as soon as possible when it reaches customs, helps avoid delays in moving perishable goods.

5. Storage

It is almost a necessity to utilize temperature-controlled facilities for storing goods. Additionally, conducting quality assurance checks is essential to maintain product integrity.

6. Customer Education

Communicating storage requirements and other important information about the goods to the end customer also becomes very crucial. This helps to make sure they handle the products correctly to maintain their quality.

With this understanding, let us dive deep into the various types of cold chain materials and packaging that are available to facilitate the transfer of perishable goods.

What Are The Types Of Cold Chain Packaging and Materials Available?

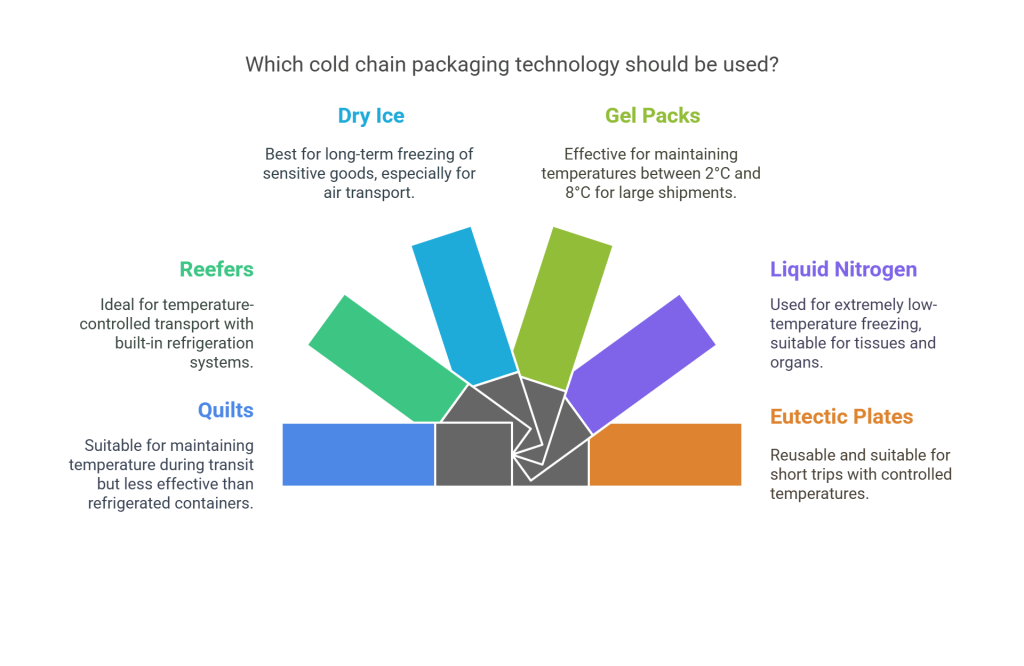

When it comes to packaging, there are a few things to think about, like how big the shipment is, what the weather’s like outside, how long it’s going to take to get there, and so on.

You need to consider all these factors before deciding on the best way to pack your goods. Here are some cold chain packaging technologies that can help you keep everything at the right temperature while it’s being transported.

1. Quilts

- These are big blankets made of insulated material that you wrap around or lay over your shipment.

- They help keep the temperature steady during transit and come in handy when you need to keep frozen goods cold.

- However, they’re not as effective as using a refrigerated container.

2. Reefers

- These are special vehicles like vans, trucks, trailers, or containers that can control the temperature inside.

- They have their own fridge system to keep things cool or warm as needed.

3. Dry Ice

- This is super cold solid carbon dioxide, about -80°C, and is used to keep things frozen for a long time.

- It’s often used for shipping food, medicine, or other sensitive goods, especially by air.

4. Gel Packs

- They are special substances that can change from solid to liquid and back again to help keep the cargo at the right temperature.

- They’re often used for big shipments of medicine or medical supplies that need to stay between 2°C and 8°C.

5. Liquid Nitrogen

- This is a really cold chemical that stays as a gas at about -196°C.

- It’s used to keep things frozen for a long time, especially when shipping foods like tissues or organs.

6. Eutectic Plates

- Just like reusable gel packs, eutectic plates are cold plates that can be used many times.

- They are most suitable for shorter trips, like delivering goods in places where the temperature is controlled, or for night deliveries.

Advantages of Cold Chain Logistics

In today’s global supply chain, cold chain logistics play a vital role in maintaining the safety, quality, and integrity of temperature-sensitive goods. From pharmaceuticals to frozen foods, effective cold chain systems enable businesses to meet customer expectations and comply with international standards.

Here are the key advantages of cold chain logistics for businesses and consumers:

1. Product Safety & Quality Assurance

Maintains the freshness, potency, and overall quality of sensitive goods such as vaccines, seafood, dairy, and specialty chemicals.

2. Regulatory Compliance

Helps companies meet strict global food and pharmaceutical regulations, ensuring adherence to industry standards and reducing risks of legal issues.

3. Reduced Waste & Spoilage

Prevents product degradation during storage and transit, which directly translates to higher profitability and reduced losses.

4. Extended Shelf Life

Provides longer product stability, ensuring consistent availability, repeat orders, and better customer satisfaction.

5. Global Market Reach

Enables businesses to expand into new geographies, offering reliable exports of perishable goods across borders.

6. Stronger Customer Trust

By delivering safe and high-quality products, businesses can enhance their brand reputation and build long-term customer loyalty.

These benefits are only possible with robust cold chain management systems in place. By combining advanced packaging, monitoring technologies, and efficient logistics strategies, organizations can minimize risks while maximizing efficiency in their cold chain operations.

Conclusion

In conclusion, mastering cold chain logistics is paramount for the global movement of temperature-sensitive goods. This complex process fundamentally depends on the accurate classification and handling of diverse cold chain items, from pharmaceuticals to perishable foods. By implementing robust and efficient cold chain management systems, businesses can not only ensure product integrity and compliance with strict regulations but also secure a competitive edge in the market.

We hope this blog has provided a comprehensive understanding of these critical elements. For expert guidance on optimizing your cold chain operations and leveraging advanced technologies, reach out to the specialists at QodeNext today.

FAQs: Mastering Cold Chain Logistics

1. What does the cold chain process entail?

The cold chain process starts with choosing suitable packaging and employing temperature-controlled technologies tailored to the specific needs of the products. Upon arrival at their destination, cold chain items are moved to temperature-controlled storage facilities until they are prepared for distribution.

2. What is the importance of cold chain logistics?

Cold chain logistics is crucial for industries that need to control temperatures to uphold product quality and safety. Sustaining the cold chain is crucial as it prevents spoilage, deterioration, and loss of effectiveness in delicate products during shipment. Cold chain supply plays a vital role in guaranteeing the quality, safety, and effectiveness of sensitive products.

3. What are some typical challenges faced in Cold Chain Logistics?

Common issues in cold processing include temperature inconsistencies, insufficient packaging, inappropriate transportation gear, and the absence of monitoring and control systems. These factors can result in fluctuations in climate control and an inability to sustain a steady temperature.

4. How can technology improve cold chain efficiency?

Technology improves cold chain efficiency by enabling real-time tracking, automated temperature control, route optimization, and data analytics, all of which help reduce spoilage, ensure compliance, and improve delivery timelines.

5. How does temperature monitoring work in cold chain logistics?

Temperature monitoring in cold chain logistics uses IoT sensors and data loggers placed inside transport containers or storage units, which continuously record and transmit temperature data to a central system, allowing immediate action if conditions go out of range.

6. Which industries rely heavily on cold chain logistics?

Industries that depend heavily on cold chain logistics include pharmaceuticals, food and beverages, agriculture, dairy, biotechnology, and floriculture, where product quality and safety are highly sensitive to temperature variations.

7. What are the key regulatory standards for cold chain logistics?

The main regulatory standards include the Food and Drug Administration (FDA) regulations for pharmaceuticals and the Hazard Analysis Critical Control Point (HACCP) system for food products. Compliance is crucial for product safety and market access.

8. How can businesses reduce cold chain logistics costs?

Businesses can reduce costs by optimizing shipping routes, consolidating shipments, investing in energy-efficient refrigeration, and leveraging data analytics to minimize waste and prevent spoilage.

9. What are the future trends in cold chain logistics?

Future trends include the wider adoption of IoT sensors for real-time monitoring, the use of blockchain technology for supply chain transparency, and the integration of automation and AI for route and inventory optimization.

10. How is a cold chain logistics service different from a cold storage facility?

A cold chain logistics service provides a full, end-to-end solution that includes transport, handling, and storage. A cold storage facility, on the other hand, is just one component, offering only temperature-controlled warehousing.