Global supply chains are under immense pressure to deliver accountability, accuracy, and traceability across every step. In this environment, achieving transparency in supply chains requires more than traditional tracking systems—it demands technologies that connect physical goods with immutable digital records. When integrated, blockchain and RFID create an infrastructure that eliminates blind spots, ensures data integrity, and enables real-time decision-making.

This blog explores the technology in detail: how blockchain networks interact with RFID systems, the architectures behind their deployment, and the challenges enterprises face when scaling them globally.

Blockchain as the Digital Trust Layer: Supply Chain Tracking

Blockchain operates as a distributed ledger technology (DLT) where each transaction is stored in cryptographically linked blocks. For supply chains, this means:

- Immutability: Once the signals are captured, nothing changes them except verified user approval.

- Decentralisation: No single stakeholder controls the ledger, reducing opportunities for manipulation.

- Smart Contracts: Automated rules enforce compliance and trigger actions (e.g., releasing payments when RFID confirms delivery).

In practice, blockchain transforms fragmented, siloed records into a unified, tamper-proof system. This foundation is essential for delivering true transparency in supply chains, as every stakeholder works with a single source of truth.

RFID as the Physical-to-Digital Connector

Radio Frequency Identification (RFID) uses electromagnetic fields to transfer data wirelessly from tags attached to objects.

Key technical components:

- Passive RFID Tags: Powered by the reader’s signal; cost-effective for tagging large volumes of items.

- Active RFID Tags: Battery-powered, capable of long-range tracking and transmitting sensor data.

- RFID Readers & Antennas: Capture tag data at warehouses, shipping docks, or retail shelves.

This constant, automated identification allows goods to broadcast their status. When combined with blockchain, RFID ensures that physical assets correspond exactly to their digital ledger entries, enhancing transparency in supply chains at scale.

How Blockchain and RFID Work Together

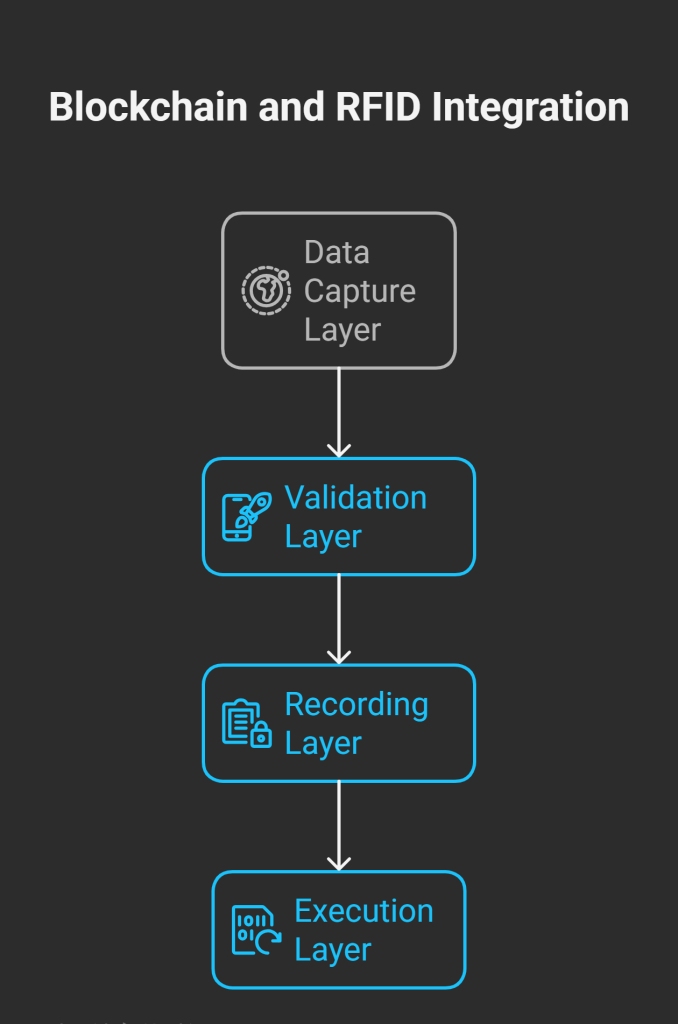

The integration of blockchain and RFID involves multiple layers of data flow:

1. Data Capture Layer

RFID readers capture identifiers, timestamps, and environmental conditions (e.g., temperature, shock).

2. Validation Layer

Captured data is transmitted to blockchain nodes, where algorithms verify authenticity. Duplicate or manipulated inputs are flagged. Data analytics separate the essential from the non-essential stuff.

3. Recording Layer

Validated data is appended to the blockchain ledger. Each update forms part of an immutable record, accessible to all stakeholders.

4. Execution Layer

Smart contracts trigger automated actions such as alerting distributors of temperature breaches in perishable goods.

This closed-loop system ensures that real-world events (captured by RFID) are mirrored with integrity in the digital ledger (managed by blockchain). Such a dual feedback loop helps blockchain and RFID bring transparency to supply chains.

Advanced Applications of Blockchain + RFID

1) Anti-Counterfeit Frameworks

Each RFID-tagged product has a unique identifier that blockchain records at origin. If counterfeiters attempt to duplicate tags, blockchain cross-verification rejects mismatched entries. This approach is being piloted in luxury goods and pharmaceuticals, where transparency in supply chains is non-negotiable.

2) Real-Time Cold Chain Monitoring

RFID sensors embedded in shipments act like watch-guards, noticing temperature and humidity changes. Blockchain immutably records any breach, enabling stakeholders to isolate compromised batches. This is critical in industries like vaccines, seafood, and dairy, where safety depends on maintaining strict conditions.

3) Automated Customs and Compliance

Customs authorities can access blockchain-verified RFID logs to confirm that cargo matches manifests. Smart contracts can block clearance if discrepancies arise, embedding compliance into the process itself and increasing transparency in supply chains.

Data Architecture Considerations

1) On-Chain vs. Off-Chain Storage

- On-Chain: High-value data such as product IDs and event triggers.

- Off-Chain: Large volumes of RFID sensor data, stored in cloud databases but referenced via blockchain hashes.

2) Consensus Mechanisms

Supply chain blockchains often use Proof of Authority (PoA) or Byzantine Fault Tolerance (BFT), as they prioritise speed and trust among known participants rather than energy-heavy Proof of Work.

3) Interoperability Protocols

RFID middleware must translate tag data into blockchain-compatible formats (often JSON). Standards like GS1 EPCIS are emerging to harmonise this process.

These architectural choices directly influence scalability and the effectiveness of transparency in supply chains.

Integration with IoT and Digital Twins

Blockchain and RFID become even more powerful when integrated with IoT sensors and digital twin models:

- IoT Sensors: These sensors have taken the entire industry, capturing granular data such as vibration, tilt, faults, bends, or GPS location.

- Digital Twins: Simulate supply chain operations in real time using verified blockchain + RFID data.

This fusion allows predictive modelling. For example, if RFID and IoT data show repeated delays at a port, the digital twin can forecast bottlenecks, enabling proactive rerouting. Such systems elevate transparency in supply chains from simple traceability to strategic foresight.

Key Implementation Challenges

- Infrastructure Costs: Large-scale RFID deployment requires thousands of readers and antennas.

- Data Overload: RFID systems generate massive datasets; blockchain must filter and store only high-value records.

- Standardisation Gaps: Lack of uniform global protocols hinders interoperability.

- Change Resistance: Supply chain partners may resist transparency if it exposes inefficiencies.

Overcoming these barriers requires collaboration among industry alliances, technology vendors, and regulators to align on best practices. Only then can transparency in supply chains become universal.

Future Outlook: Autonomous Supply Chains

The long-term trajectory points toward autonomous supply networks, where RFID-tagged goods interact directly with blockchain-based smart contracts. Payments, insurance claims, and regulatory clearances will execute automatically without human mediation.

As 5G, edge computing, and AI converge with blockchain and RFID, businesses will achieve self-regulating ecosystems where trust is embedded into system design. In this future, transparency in supply chains will shift from a competitive advantage to a baseline expectation.

Conclusion

Blockchain and RFID are not devices manufactured for the future. They have already arrived and are setting new benchmarks for logistics operations. RFID tags ensure accurate, automated physical tracking, while blockchain locks this data into immutable, universally accessible ledgers. Together, they create ecosystems where data integrity, trust, and efficiency are inseparable.

Building networks with transparency in supply chains is not just optional; it’s a survival. Companies that adopt these technologies today will define the trusted, autonomous supply chains of tomorrow. Do you want to explore these smart tracking tools for your supply chain processes? Feel free to contact Qodenext today.

FAQs – Blockchain and RFID Supply Chain

1. Why can’t RFID alone ensure transparency?

RFID identifies and tracks goods, but without blockchain, data can be tampered with or siloed. Blockchain ensures immutability, making RFID data trustworthy.

2. What type of blockchain suits supply chains best?

Permissioned blockchains using consensus models like Proof of Authority or BFT are preferred, as they balance speed with controlled access.

3. Can blockchain and RFID scale for global logistics?

Yes, but scalability requires hybrid architectures—on-chain for critical events and off-chain for bulk data. This ensures speed while maintaining transparency in supply chains.

4. How do smart contracts add value?

They automate compliance, payments, and alerts based on RFID events. For instance, payment can be auto-released when a shipment arrives and RFID verifies delivery.

5. Are there industries leading adoption?

Pharmaceuticals, luxury goods, and perishable food supply chains are early adopters because they face high stakes in counterfeiting and safety.