Introduction

In today’s global economy, supply chains are essential for business success. Whether it’s a smartphone assembled in Vietnam, coffee sourced from Brazil, or groceries delivered to your home, each product’s journey depends on how effectively a company plans, coordinates, and optimizes its supply network.Supply chain management tools play a crucial role here. They provide the digital infrastructure that helps organizations manage complexity, anticipate risks, and transform operational chaos into a strategic edge.

Let’s examine how these tools influence modern supply chains, the types that exist, and how companies use them to make smarter decisions and improve performance.

Understanding the Core Supply Chain Components

Before selecting a tool, it’s important to understand the structure it supports. At its core, a supply chain consists of five interconnected components:

| Component | Purpose | Common Challenges |

|---|---|---|

| Procurement & Sourcing | Acquiring materials and services | Supplier reliability, cost changes |

| Production & Manufacturing | Turning materials into finished goods | Quality control, downtime |

| Inventory & Warehousing | Managing and storing goods | Overstocking, stockouts |

| Transportation & Logistics | Moving goods through the network | High freight costs, delays |

| Distribution & Fulfillment | Delivering to customers | Delivery speed, last-mile costs |

When these components operate in harmony, the entire chain runs smoothly. However, if one component fails, the effects can disrupt the entire process.

That’s why effective supply chain management focuses not only on daily operations but also on optimizing each part to support long-term business goals.

Why Supply Chain Management Tools Matter More Than Ever

Supply chains are no longer simple or predictable. Market changes, geopolitical disruptions, and rising customer expectations make traditional planning inadequate.

Supply chain management tools provide companies with visibility, control, and insights throughout the entire chain. They gather real-time data, conduct predictive analyses, and enable leaders to plan based on informed insights instead of guesswork.

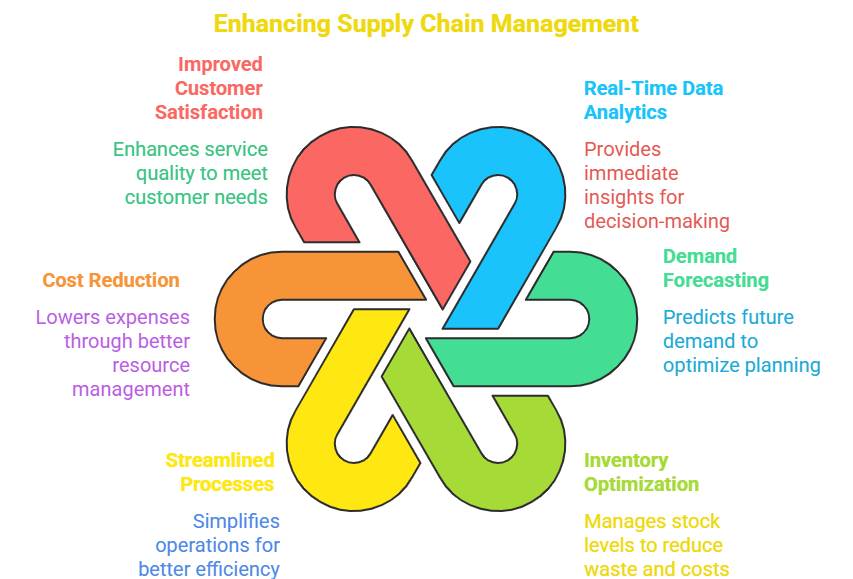

Key Benefits:

- End-to-end visibility: Track where materials and orders are across the network.

- Forecast accuracy: Predict demand to avoid under- or overproduction.

- Risk mitigation: Identify potential disruptions and simulate responses.

- Inventory optimization: Balance cost, availability, and storage efficiency.

- Collaboration: Bring suppliers, logistics partners, and teams together on one platform.

In essence, a supply chain tool acts like a command center—helping businesses see, think, and act more quickly.

Types of Supply Chain Management Tools

Not every organization needs the same tool. The right selection depends on your industry, scale, and goals.

Below are the major types of supply chain management tools and their primary functions.

1. Supply Chain Planning Tools

These tools help companies align supply and demand by forecasting, modeling scenarios, and planning capacity. They serve as the brain of strategic operations, balancing production, inventory, and logistics in advance.

Example: Heineken uses AI-driven planning tools to forecast demand in 190 countries, aligning its brewing and distribution schedules with local trends.

2. Inventory Management Systems

These systems track stock levels, reorder points, and product visibility. They ensure the right amount of stock to meet demand without tying up too much capital.

Example: Zara’s parent company, Inditex, uses a sophisticated inventory system integrated with store sales data to restock stores twice a week based on real-time demand.

3. Warehouse Management Systems (WMS)

A WMS oversees how goods are stored, picked, packed, and shipped within a warehouse. By optimizing layout and movement, it reduces time and errors.

Example: Walmart’s distribution centers use IoT sensors and robotics to enhance order accuracy and efficiency.

4. Transportation Management Systems (TMS)

A TMS optimizes routes, carrier selection, and freight costs—critical for companies where transportation represents a significant expense.

Example: Unilever’s global Transportation Management Systems consolidates loads to reduce empty miles and emissions, cutting costs and supporting sustainability.

5. Supplier Relationship Management (SRM) Tools

These tools manage sourcing, supplier performance, and risk monitoring—crucial for supply chain resilience.

Example: Apple’s Supplier Relationship Management system monitors supplier networks, ensuring sustainability and labor compliance while keeping production on track.

6. End-to-End Supply Chain Platforms

These integrated systems combine planning, logistics, and analytics into one cohesive platform.

Example: Procter & Gamble uses SAP’s integrated suite to connect factories, suppliers, and distributors globally, ensuring synchronization across thousands of products.

What Makes a Tool Strategic

Many businesses gather supply chain data, but few turn it into actionable insights. The key is using data to anticipate rather than react.

A supply chain tool becomes strategic when it allows you to:

- Model “what-if” scenarios (e.g., what if shipping costs double?)

- Connect demand forecasts with supplier capacity

- Simulate production constraints in advance

- Optimize trade-offs between cost, speed, and sustainability

Companies like Amazon thrive because predictive algorithms forecast consumer demand weeks in advance—guiding inventory placement before orders arrive.

How to Choose the Right Supply Chain Tool

With so many choices, selecting the right tool can be daunting. Here’s a simple framework to guide your decision:

| Step | What to Consider | Why It Matters |

|---|---|---|

| 1 | Identify Your Pain Points | Focus prevents over-investing in the wrong area. |

| 2 | Define Strategic Goals | Aligns tools with business objectives. |

| 3 | Assess Data Readiness | Poor data leads to misleading insights. |

| 4 | Evaluate Integration | Isolated tools reduce efficiency. |

| 5 | Pilot & Measure | Start small; quick wins build confidence. |

Companies following this approach often see measurable returns within a year through lower inventory costs and improved service levels.

Avoiding Common Pitfalls in Implementation

Even the best technology can fail without a solid foundation. Avoid these common mistakes:

- Starting big and failing fast: Begin with a pilot before scaling.

- Ignoring user adoption: Train teams early; they must trust the tool.

- Neglecting integration: Disconnected tools create more work.

- Skipping measurement: Define KPIs before rollout.

A tool is only as strategic as the process it supports.

The Future of Supply Chain Optimization

The next generation of supply chain tools is shaped by data, automation, and sustainability.

Key Trends:

- Artificial Intelligence (AI): Predictive analytics for demand and disruption management.

- Digital Twins: Virtual models for testing “what-if” scenarios.

- Cloud Collaboration: Shared platforms linking all stakeholders.

- Sustainability Metrics: Tracking carbon emissions and ethical sourcing.

- Blockchain Transparency: Enhancing traceability across industries.

Companies embracing these capabilities are not just surviving disruptions—they’re building resilient, future-ready systems.

FAQs: Best Supply Chain Management Tools for Optimization in 2025

1. How are supply chain management tools different from ERP systems?

ERP manages overall processes, while SCM tools focus on optimizing sourcing, production, logistics, and distribution.

2. What are some top-rated tools in 2025?

SAP Integrated Business Planning, Blue Yonder, Kinaxis RapidResponse, and E2Open lead global SCM planning.

3. How long does it take to see results?

Most firms see improvements in 3–6 months—especially in forecasting and inventory accuracy.

4. Are these tools suitable for small businesses?

Yes. Many offer modular, cloud-based solutions that scale with business size and budget.

5. Which supply chain areas benefit most from automation?

Inventory management, transport routing, and demand forecasting show the quickest ROI.

Conclusion

At its best, a supply chain tool is not just software—it’s a strategic asset that connects every component, predicts challenges, and transforms operational data into a competitive edge.

To summarize:

- Understand your supply chain components and bottlenecks.

- Choose tools that align with your strategic goals.

- Start small, measure results, and scale wisely.

- Keep optimizing—supply chain excellence is an ongoing process.

Whether you’re a fast-growing D2C brand or a large manufacturer, success depends on how expertly you manage complexity. The right supply chain management tool with qodenext helps you see the big picture—and act before your competitors do.