The automotive industry faces a multitude of challenges in today’s dynamic business environment. Amidst evolving customer expectations and market dynamics, managing inventory effectively has become a critical aspect for automakers and dealerships alike.

In 2023, the automotive industry is confronted with a range of pressing challenges, including supply chain disruptions, fluctuating customer demand, and rising production costs. To maintain a competitive edge, it is crucial to address these challenges head-on and devise strategic solutions for efficient inventory management.

In this blog, we will explore the key automotive industry challenges and delve into innovative solutions to navigate the complexities of inventory management in 2023. Join us as we uncover the strategies that can drive success in this ever-evolving landscape.

What Is a Automotive Supply Chain ?

An automotive supply chain refers to the interconnected network of companies and processes involved in the production and distribution of automotive components and vehicles.

It encompasses various stages, starting from the procurement of raw materials and parts, through manufacturing and assembly, to the delivery of finished vehicles to dealerships or customers.

The automotive supply chain plays a crucial role in ensuring the availability of components, optimizing production processes, and delivering high-quality vehicles to the market. Listed below are the six key features of the automotive supply chain:

1.Globalization

The automotive supply chain is highly globalized, with companies sourcing materials and components from various countries to take advantage of cost efficiencies and access specialized expertise.

2.Complex network:

The supply chain involves numerous suppliers, manufacturers, logistics providers, and distributors, forming a complex web of relationships and dependencies.

3.Just-in-time manufacturing:

The automotive industry relies heavily on just-in-time manufacturing principles, where components are delivered precisely when needed to minimize inventory costs and improve efficiency.

4.Quality control:

Given the stringent quality requirements in the automotive sector, quality control is a critical aspect of the supply chain. Stringent measures are implemented to ensure that all components and vehicles meet safety and performance standards.

5.Regulatory compliance:

The automotive industry is subject to various regulations related to safety, emissions, and labor standards. Supply chain participants must adhere to these regulations to ensure compliance throughout the production and distribution processes.

6.Innovation and technology integration:

The automotive supply chain continuously embraces innovation and technology advancements. From the use of advanced manufacturing techniques like robotics and automation to the implementation of digital solutions for inventory management and supply chain visibility, technology plays a vital role in optimizing operations.

These features highlight the complexity and dynamic nature of the automotive supply chain, which requires efficient coordination, collaboration, and continuous improvement among its various stakeholders to ensure the timely delivery of high-quality vehicles to customers worldwide.

Automotive Industry Challenges in Inventory Management

Inventory management in the automotive industry poses several challenges due to its complex and dynamic nature. One of the primary challenges is the vast range of components and parts required to assemble a vehicle, leading to a large inventory with diverse items.

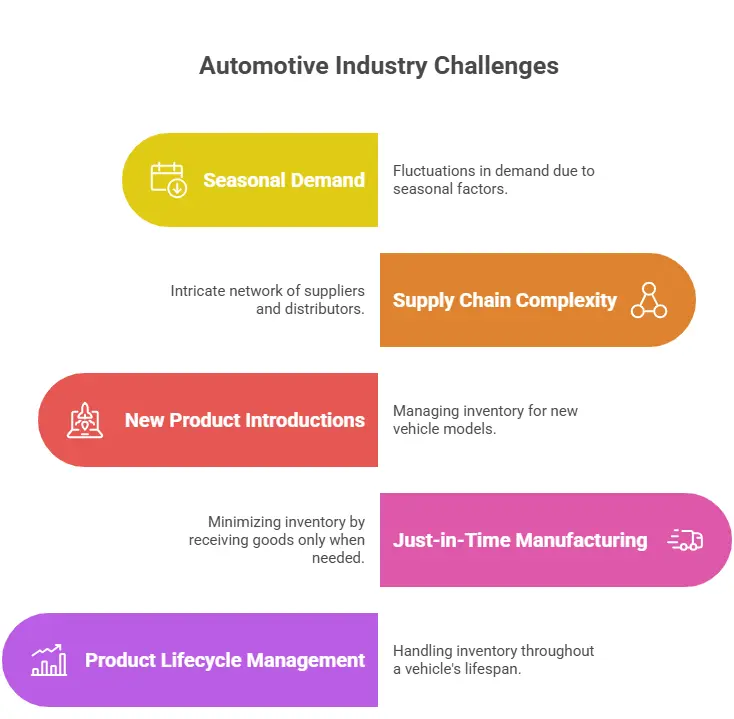

This necessitates effective tracking and management to avoid stockouts or excess inventory, which can have significant financial implications. Additionally, the following five challenges further impact inventory management in the automotive industry:

1.Seasonal Demand:

The automotive industry experiences fluctuating demand throughout the year due to seasonal factors, such as increased sales during holidays or specific weather conditions. Managing inventory levels to match demand variations is crucial to avoid excess stock during low-demand periods and prevent stock outs during peak seasons.

2.Supply Chain Complexity:

Automotive manufacturers often have a vast network of suppliers and distributors, both domestic and international. Coordinating the movement of parts and components across various locations adds complexity to inventory management, as delays or disruptions in the supply chain can lead to production interruptions or excess inventory.

3.New Product Introductions:

The automotive industry constantly introduces new models, variants, and upgrades to meet changing customer preferences and market trends. Introducing new products while effectively managing existing inventory requires careful planning and coordination to ensure a smooth transition and prevent the obsolescence of older parts.

4.Just-in-Time Manufacturing:

Many automotive manufacturers adopt a just-in-time (JIT) manufacturing approach to minimize inventory holding costs. While JIT can improve efficiency, it also increases the risk of stockouts if supply chain disruptions occur or forecasts are inaccurate. Maintaining a delicate balance between lean inventory and meeting production demands is a significant challenge.

5.Product Lifecycle Management:

The automotive industry faces challenges related to managing inventory throughout a product’s lifecycle. As vehicles and components go through different stages, such as introduction, growth, maturity, and decline, inventory levels need to be adjusted accordingly to prevent excess inventory or shortage of discontinued parts.

Addressing these challenges requires implementing advanced inventory management systems, leveraging data analytics for demand forecasting, improving communication and collaboration with suppliers, and establishing effective inventory control policies. By effectively managing inventory, automotive companies can enhance operational efficiency, reduce costs, and meet customer demands more efficiently.

Solutions for Automotive Industry in Inventory Management

Effective inventory management is crucial for the automotive industry to streamline operations, reduce costs, and enhance customer satisfaction. By implementing efficient solutions, automakers and dealerships can optimize inventory levels, improve supply chain visibility, and minimize stockouts. Here are five solutions that can significantly benefit the automotive industry in inventory management:

1.Demand Forecasting:

Leveraging advanced analytics and historical data, demand forecasting helps anticipate customer demand accurately. This enables automakers to optimize inventory levels, reduce excess stock, and maintain a balanced supply chain

2.Just-in-Time (JIT) Inventory: .

JIT inventory management focuses on minimizing inventory holding costs by receiving and stocking components and finished goods at the last possible moment. By synchronizing production with demand, JIT helps reduce waste, carrying costs, and the risk of obsolescence

3.Real-Time Inventory Tracking:

Utilizing technologies like RFID (Radio Frequency Identification) or barcode systems, real-time inventory tracking provides visibility into the movement and location of automotive parts and vehicles throughout the supply chain. This enables better inventory control, faster order fulfillment, and reduced manual errors.

4.Collaborative Supply Chain Management:

Establishing strong partnerships and collaborations with suppliers, distributors, and dealerships is crucial for effective inventory management. By sharing real-time data, demand forecasts, and production schedules, all stakeholders can align their operations and optimize inventory levels across the supply chain.

5.Automated Replenishment Systems:

Automated replenishment systems use intelligent algorithms to monitor inventory levels and trigger automatic reordering of parts or vehicles when predetermined thresholds are reached. This helps eliminate manual intervention, reduce lead times, and ensure consistent availability of critical components.

By implementing these solutions, the automotive industry can enhance inventory management practices, reduce costs, and improve overall operational efficiency, ultimately resulting in improved customer satisfaction and profitability.

Conclusion

In conclusion, we can say that the automotive industry faces several challenges in inventory management in 2023, including increasing complexity due to multiple vehicle models and variants, global supply chain disruptions, and demand fluctuations.

To address these challenges, companies need robust solutions that offer real-time visibility, predictive analytics, and streamlined processes. Qodenext, a leading technology provider, offers an innovative inventory management platform specifically designed for the automotive industry.

With their advanced features and intelligent algorithms, Qodenext can help automakers optimize inventory levels, reduce carrying costs, minimize stockouts, and enhance overall supply chain efficiency. Contact Qodenext today to transform your inventory management and stay ahead of the competition.

1.What are the main challenges facing inventory management in the automotive industry in 2023?

Key challenges include managing a wide variety of parts, fluctuating seasonal demand, complex global supply chains, just-in-time manufacturing risks, and handling product lifecycle changes.

2.How does seasonal demand impact automotive inventory management?

Seasonal demand creates fluctuations in vehicle and parts sales, requiring careful inventory adjustments to avoid excess stock during slow periods and stockouts during peaks.

3.Why is supply chain complexity a critical challenge for automotive inventory?

Automotive supply chains span multiple countries and suppliers, making coordination difficult. Delays or disruptions can cause production stoppages or inventory imbalances.

4.What role does just-in-time (JIT) manufacturing play in automotive inventory challenges?

JIT reduces costs by minimizing inventory on hand but increases vulnerability to supply disruptions, demanding highly accurate forecasting and quick supplier responsiveness.

5.How can advanced demand forecasting improve automotive inventory management?

Using data analytics and historical sales patterns, demand forecasting predicts customer needs more accurately, helping optimize inventory levels and reduce carrying costs.

6.What are the benefits of real-time inventory tracking for automotive companies?

Technologies like RFID and barcode systems provide visibility on parts and vehicle location, accelerating order fulfillment, enhancing accuracy, and reducing manual errors.

7.How important is collaboration across the automotive supply chain for effective inventory control?

Sharing real-time data and forecasts among manufacturers, suppliers, and dealers aligns production and deliveries, helping prevent excess inventory or shortages.

8.What is an automated replenishment system, and how does it aid automotive inventory management?

Automated systems use intelligent triggers to reorder parts or vehicles when stock falls below certain thresholds, reducing manual oversight and preventing stockouts.

9.How do new product introductions pose inventory management challenges in the automotive industry?

Frequent model updates and variant launches require careful planning to phase out old inventory without excess, preventing obsolete stock and losses.

10.Why is product lifecycle management critical in automotive inventory planning?

Inventory must be adjusted as products go from introduction to decline, ensuring availability for ongoing demand while avoiding costly overstock of discontinued parts.