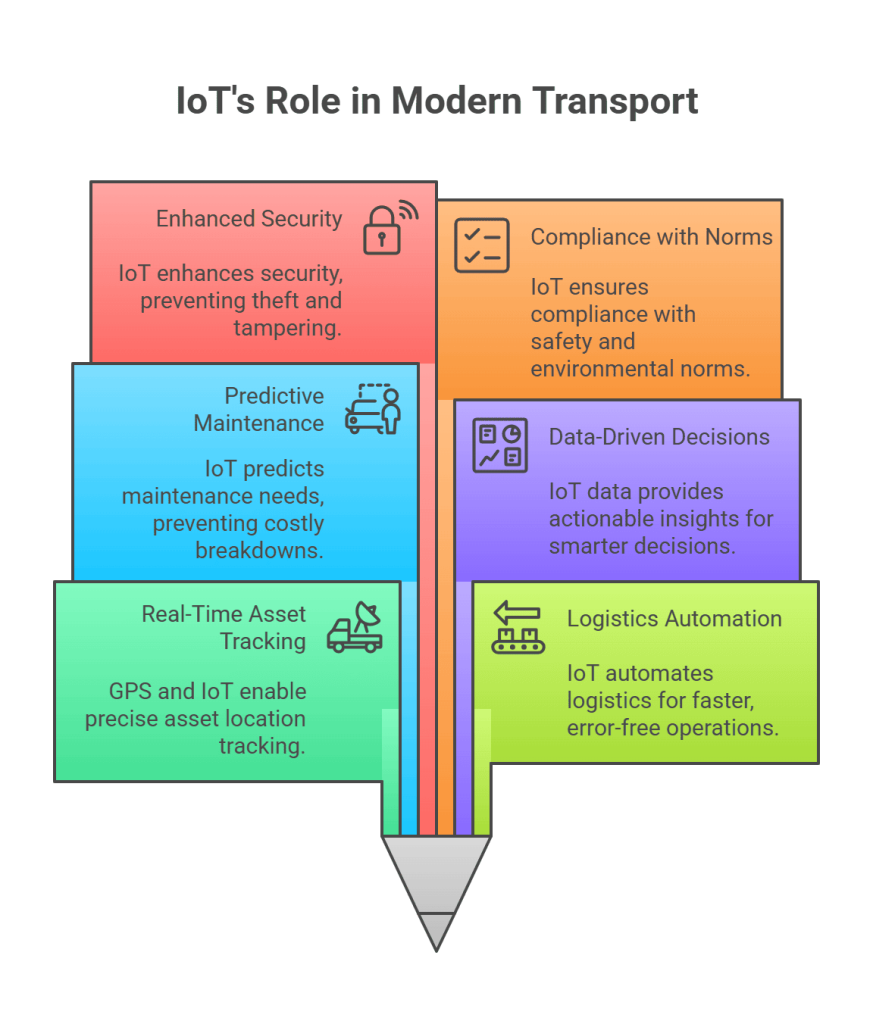

In a sector where time, precision, and visibility define success, the Internet of Things (IoT) is quietly revolutionizing how logistics and transportation companies operate.

From live location updates to predictive maintenance, IoT in logistics is more than a trend. It’s a fundamental shift in how assets are tracked, managed, and optimized.

Let’s explore how this technology is reshaping the industry, making operations more transparent, efficient, and scalable.

Let’s dive right in.

1. Real-Time Asset Tracking with GPS and IoT

The backbone of asset tracking IoT lies in GPS sensors, RFID tags, and cellular networks that work together to offer real-time data.

These devices monitor vehicles, containers, pallets, and even individual items, helping companies reduce loss, delays, and inventory inaccuracies.

GPS tracking IoT allows companies to:

- Track fleet location down to street-level accuracy

- Monitor idle times and route deviations

- Set geofencing alerts for unauthorized movements

For instance, DHL has adopted IoT-based smart sensors across its global supply chain to track shipments and avoid cold-chain spoilage in pharmaceuticals. Their “SmartSensor” technology enables temperature, humidity, and shock tracking – crucial for high-value goods.

Now that we understand real-time tracking, let’s explore how IoT boosts operational efficiency.

2. Logistics Automation for Efficiency and Scale

Logistics companies are under pressure to move faster, with fewer errors. That’s where logistics automation driven by IoT steps in. IoT devices automate:

- Inventory updates via smart shelves and RFID tags

- Predictive maintenance alerts for fleet vehicles

- Load optimization using weight and pressure sensors

FedEx, for example, uses IoT-powered scanners and conveyor sensors to streamline parcel sorting in their distribution hubs. This helps reduce manual errors and increase throughput.

With efficiency covered, let’s dive into another key reason for IoT adoption – predictive asset health.

3. Predictive Maintenance and Asset Health

The cost of breakdowns in the middle of a logistics chain can be massive. With IoT in transportation, companies can proactively monitor vehicle health.

Using vibration, temperature, and engine sensors, IoT systems detect anomalies and trigger alerts before a failure occurs. This approach helps:

- Avoid unexpected downtimes

- Optimize maintenance schedules

- Extend asset lifespan

Maersk, the global shipping giant, uses IoT on its cargo vessels to monitor engine and container performance in real-time, reducing fuel usage and maintenance costs by millions annually.

Now that predictive maintenance is in play, what about improving decision-making through data?

4. Smarter Decisions with Data-Driven Insights

IoT in supply chain management doesn’t just collect data; it turns it into actionable insights. Cloud platforms connected to IoT devices help companies:

- Forecast delays

- Improve delivery ETAs

- Analyze route efficiencies

- Benchmark carrier performance

UPS has been a pioneer in this area with its ORION (On-Road Integrated Optimization and Navigation) system. It leverages IoT data to optimize delivery routes, saving the company an estimated 10 million gallons of fuel annually.

After exploring data insights, let’s move into how security is elevated through IoT.

5. Enhanced Security and Theft Prevention

When assets are on the move, theft and tampering risks rise.

With asset tracking IoT, companies can detect:

- Unscheduled access to containers

- Tampering with package seals

- Movement outside designated routes

IoT-enabled locks and seals offer alerts and remote locking features. Walmart has used IoT-integrated trailers that log unauthorized door openings in real time, helping reduce shrinkage in high-theft areas.

6. Compliance with Safety and Environmental Norms

From temperature logs to emissions tracking, IoT in logistics helps meet compliance mandates. IoT systems:

- Monitor driver behavior for road safety compliance

- Track emissions for sustainability reporting

- Log environmental conditions for sensitive cargo

Amazon uses IoT sensors for cold-chain compliance in its grocery delivery arm, ensuring perishables stay within regulatory temperature limits. These logs are digitally stored for audits, minimizing paperwork.

The benefits of IoT in transportation extend beyond just cost savings or speed.

It fosters an environment of continuous visibility, data-driven optimization, and operational resilience. Whether it’s logistics automation or GPS tracking IoT, businesses are gaining more control over their assets than ever before.

More importantly, these use cases show that IoT in supply chain management is not reserved for tech giants alone. Affordable sensors, cloud connectivity, and scalable platforms have made it accessible to SMEs too.

FAQs: 6 Reasons Why Transport Companies Are Investing in IoT for the Long Run

1. What industries benefit most from IoT asset tracking?

Apart from transport and logistics, industries like agriculture, pharmaceuticals, retail, and construction benefit from IoT-based asset tracking, especially for mobile or high-value assets.

2. How secure is IoT-based tracking for logistics?

Most systems today use encryption, multi-factor authentication, and blockchain-based ledgers to ensure the integrity and security of asset tracking data.

3. Can small logistics companies afford IoT systems?

Yes, many affordable plug-and-play IoT platforms exist today with pay-as-you-scale models, making them accessible to startups and growing logistics providers.

4. What are some challenges when implementing IoT in transportation?

Some challenges include the initial cost of devices and integration, ensuring reliable network coverage for data transfer, cybersecurity risks, and training staff to use new systems effectively. Planning and partnering with experienced IoT providers can help overcome these issues.

5. How does IoT help transport companies lower their environmental impact?

IoT enables smarter route planning, reduces vehicle idling, and monitors conditions that can raise emissions or cause spoilage. By optimizing operations and reducing wasted fuel or goods, companies can lower their carbon footprint and operate more sustainably.

6. Can IoT systems be scaled as a transport company grows?

Yes, modern IoT platforms are designed to be scalable. Companies can easily add new devices, expand asset tracking, and connect additional vehicles or shipment types as their business expands, without overhauling their original investment.

Conclusion

As customer expectations grow and margins tighten, the choice becomes clear: embrace IoT in supply chain management, or risk falling behind.

For modern logistics providers, IoT isn’t just a competitive advantage – it’s the backbone of operational excellence. In short, the logistics leaders of tomorrow are already investing in IoT today.